5

1. Disconnect power.

2. Remove the refrigerant from the existing system per the

manufacturer’s instructions provided with the recovery

system being used. Connect the R-22 gauge set is

connected to both sides of the refrigerant system (as shown),

and verify that the entire system is void of refrigerant in

accordance with the manufacturer’s instructions provided

with the recovery system being used.

3. Disconnect the liquid and vapor lines from the existing

outdoor unit.

4. Remove the existing outdoor unit.

5. Set the new R-410A outdoor unit and connect the refrigerant

lines. See “Connect Refrigerant Lines” steps 1 through 5. Do

not evacuate the lines.

6. Remove the existing R-22 refrigerant flow control orifice or

thermal expansion valve on the indoor coil, and use a field

provided fitting to reconnect the lines.

Thermal Expansion Valve

Orifice

7. Remove the caps from the suction and liquid pressure taps.

8. Remove the valve cores.

9. Connect an R-22 cylinder with clean refrigerant to the suction

pressure tap.

10. Connect the R-22 gauge set to the liquid line service valve

and connect a recovery machine with an empty recovery tank

to the gauge set.

11. Set the recovery machine for liquid recovery and start the

recovery machine in accordance with the manufacturer’s

instructions provided with the recovery system being used.

12. Open the gauge set valves to allow the recovery machine to

run until a vacuum level less than 0" Hg (gauge pressure) is

established in the existing system line set and indoor coil.

13. Invert the cylinder of clean R-22 and open its valve to allow

liquid refrigerant to flow into the system through the vapor

line valve.

14. After all of the liquid refrigerant has been recovered, switch

the recovery machine to vapor recovery to allow the recovery

machine to run until a vacuum level less than 0" Hg (gauge

pressure) is established in the existing system line set and

indoor coil in accordance with the manufacturer’s instructions

provided with the recovery system being used.

NOTE: A single system flush should remove all of the mineral oil

from the existing refrigerant lines and indoor coil. A second

flushing may be done (using clean refrigerant) if insufficient

amounts of mineral oil were removed during the first flush. A

second flushing may be required to ensure that the maximum

amount of oil is removed.

15. Close the valves on the inverted R-22 cylinder and gauge set.

16. Remove the recovery machine, gauges, R-22 cylinder and the

field provided fitting installed in Step 6.

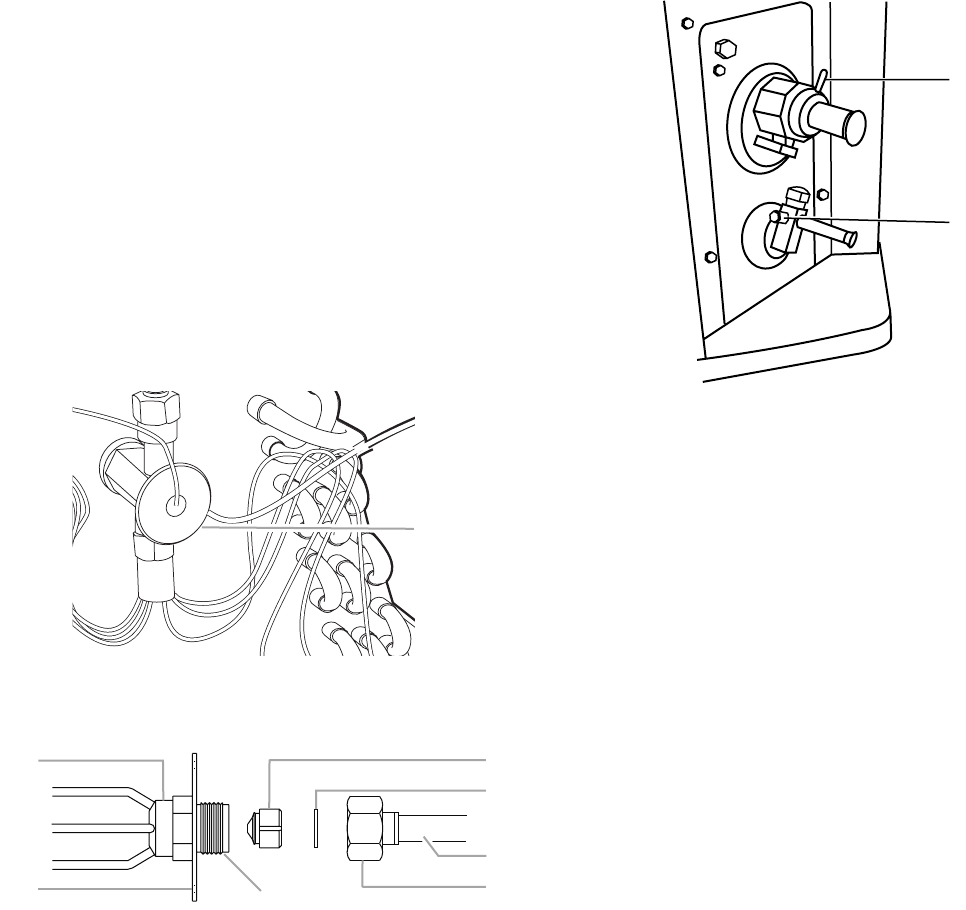

A.Thermal expansion valve

A. Distributor fitting

B. Mounting flange

C. Piston orifice

D.Ring seal (supplied)

E.Orifice extension stub

F. 0.812" brass hex nut

G. Brass hex fitting

A

A

B

D

E

C

F

G

A. Suction pressure tap

B. Liquid pressure tap

A

B