GAUGE

PORT BOSS

STORAGE:

If the pump and coupling are to be stored, drain the pump

and pour non-detergent SAE 30-weight oil into the pump port.

Apply grease to the pump or the coupling shaft extension, if

present or accessible.

Viking suggests rotating the pump shaft every 30 days to

circulate the oil in the pump. The coupling should be stored

in a dry area.

Note: If the liquid to be pumped reacts with oil, use an

acceptable alternate.

SUGGESTED REPAIR TOOLS:

The following tools are required to properly repair Series 855

pumps. These tools are in addition to standard mechanics’

tools such as open-end wrenches, pliers, screwdrivers, etc.

Most of the items can be obtained from an industrial supply

house.

1. Soft face hammer

2. Metric Allen wrenches (for set screws)

3. Torque Wrench with a locknut socket

4. External snap ring pliers - (Viking Part # 2-810-029-375)

5. Internal snap ring pliers - (Viking Part # 2- 810-047-999)

6. Arbor press

7. Brass bar

8. Hook style spanner wrench

SECTION TSM 685.2 ISSUE C PAGE 4 OF 16

MAINTENANCE

Series 855 pumps are designed for long, trouble-free service

life under a wide variety of application conditions with a

minimum of maintenance. The points listed below will help

provide long service life.

CLEANING PUMP:

Keep the pump as clean as possible. This will facilitate

inspection, adjustment and repair work.

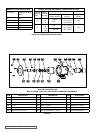

ROTOR

HEAD

IDLER PIN

RELIEF VALVE

(shown with optional

RV coverplate)

HEAD

GASKET

SEAL

IDLER

CUTAWAY VIEW MAG DRIVE PUMP, MD2-B

WITH BEARING CARRIER ILLUSTRATED

INNER MAGNET

ASSEMBLY

OUTER

MAGNET

ASSEMBLY

BEARING

CARRIER

ASSEMBLY

(Optional)

CANISTER

TEMPERATURE

PROBE HOLE

CANISTER

O-RING

CASING

BUSHING

BRACKET

SHAFT

FIGURE 4

CASING

LUBRICATION:

Some bearing carriers require external lubrication. This must

be applied slowly with a handgun to lubrication fittings every

500 hours of operation with multi-purpose grease, NLGI # 2.

Do not over-grease. Applications involving very high or low

temperatures will require other types of lubrication. Refer to

ESB-515. Consult factory with specific lubrication questions.