– 7 –

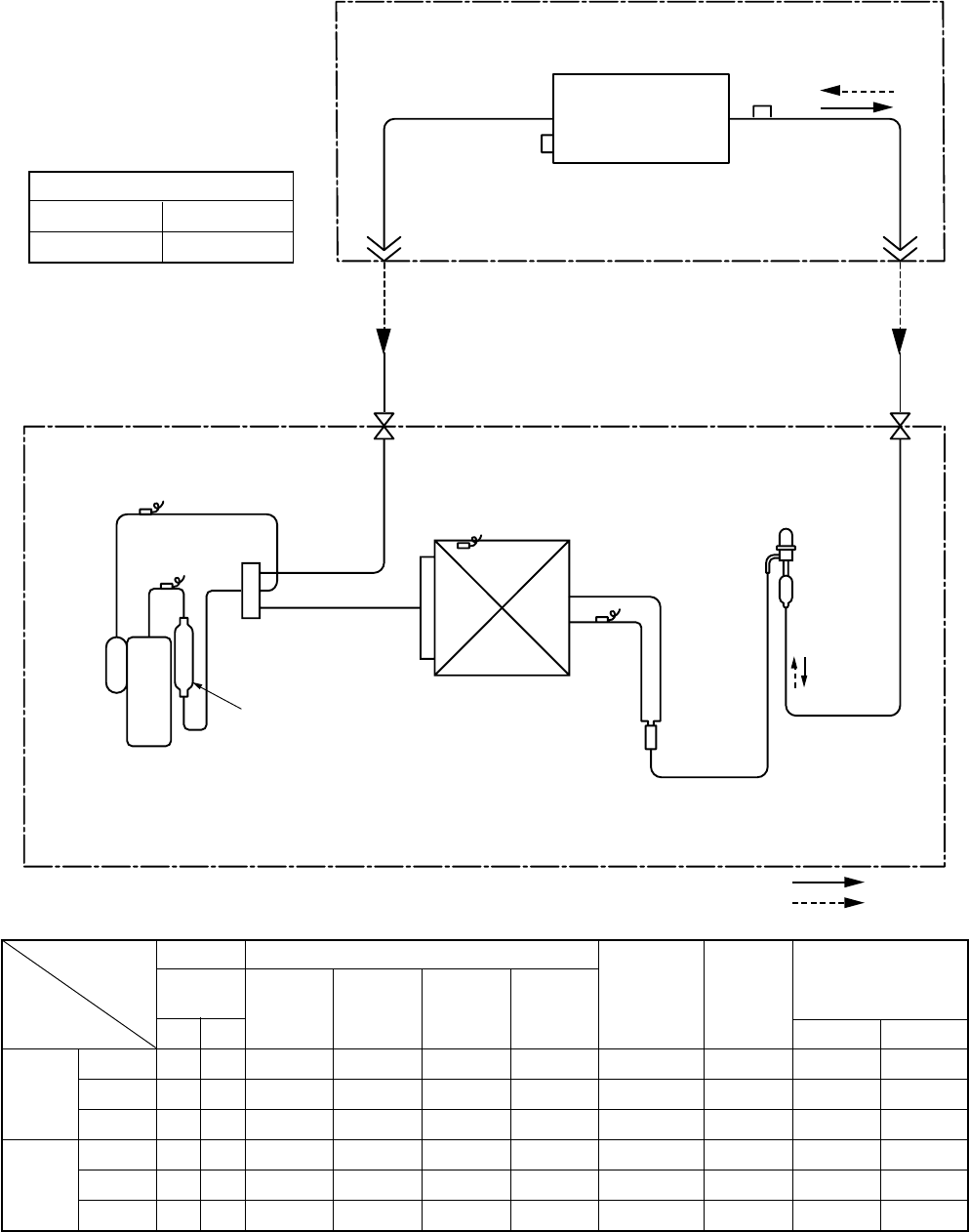

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

3-1. RAV-SM560XT-E / RAV-SM560AT-E

Pressure Pipe surface temperature (°C)

(MPa) Discharge Suction

Indoor heat Outdoor heat Indoor

exchanger exchanger fan

Pd Ps (TD) (TS) (TC) (TE) Indoor Outdoor

Standard 3.1 0.9 85 13 10 47 74 HIGH 27/19 35/–

Cooling Overload 3.8 1.0 96 13 12 60 71 HIGH 32/24 43/–

Low load 0.9 0.5 25 7 10 5 28 LOW 18/15.5 –5/–

Standard 2.8 0.6 87 3 46 1 87 HIGH 20/– 7/6

Heating Overload 3.3 1.1 78 22 55 16 55 LOW 30.– 24/18

Low load 1.7 0.2 110 –20 26 –22 110 HIGH 0 –20/(70%)

Indoor/Outdoor

temp. conditions

(DB/WB) (°C)

Compressor

revolutions

per second

(rps)

*

* 4 poles are provided to this compressor.

The compressor frequency (Hz) measured with a clamp meter is 2 times of revolutions (rps) of the compressor.

Indoor unit

Outdoor unit

TCJ

sensor

Air heat exchanger

Strainer

TC sensor

Refrigerant pipe

at liquid side

Outer dia. ∅B

Refrigerant pipe

at gas side

Outer dia. ∅A

Packed valve

Outer dia. ∅B

Packed valve

Outer dia. ∅A

Max

30m

TS sensor

TD sensor

TO sensor

TE

sensor

Distributor

4-way valve

(VT7101D)

Muffler

∅19 x L160

Rotary compressor

(DA130A1F-23F)

Heat exchanger

∅8 multiple thread

ripple 1 row 22 stages

FP1.3 flat fin

PMV

(SKV-18D26)

R410A 0.9 kg

Cooling

Heating

Outer diameter of refrigerant pipe

Gas side ∅A Liquid side ∅B

6.4 mm 12.7 mm