– 14 –

Table 6-2-1 Thicknesses of annealed copper pipes

Thickness (mm)

Nominal diameter Outer diameter (mm) R410A R22

1/4 6.35 0.80 0.80

3/8 9.52 0.80 0.80

1/2 12.70 0.80 0.80

5/8 15.88 1.00 1.00

b) Socket joints

Socket joints are such that they are brazed for

connections, and used mainly for thick pipings

whose diameter is larger than 20 mm.

Thicknesses of socket joints are as shown in

Table 6-2-2.

(2) Joints

For copper pipes, flare joints or socket joints are

used. Prior to use, be sure to remove all

contaminants.

a) Flare joints

Flare joints used to connect the copper pipes

cannot be used for pipings whose outer

diameter exceeds 20 mm. In such a case,

socket joints can be used.

Sizes of flare pipe ends, flare joint ends and

flare nuts are as shown in Tables 6-2-3 to 6-2-6

below.

Table 6-2-2 Minimum thicknesses of socket joints

Nominal diameter

Reference outer diameter of Minimum joint thickness

copper pipe jointed (mm) (mm)

1/4 6.35 0.50

3/8 9.52 0.60

1/2 12.70 0.70

5/8 15.88 0.80

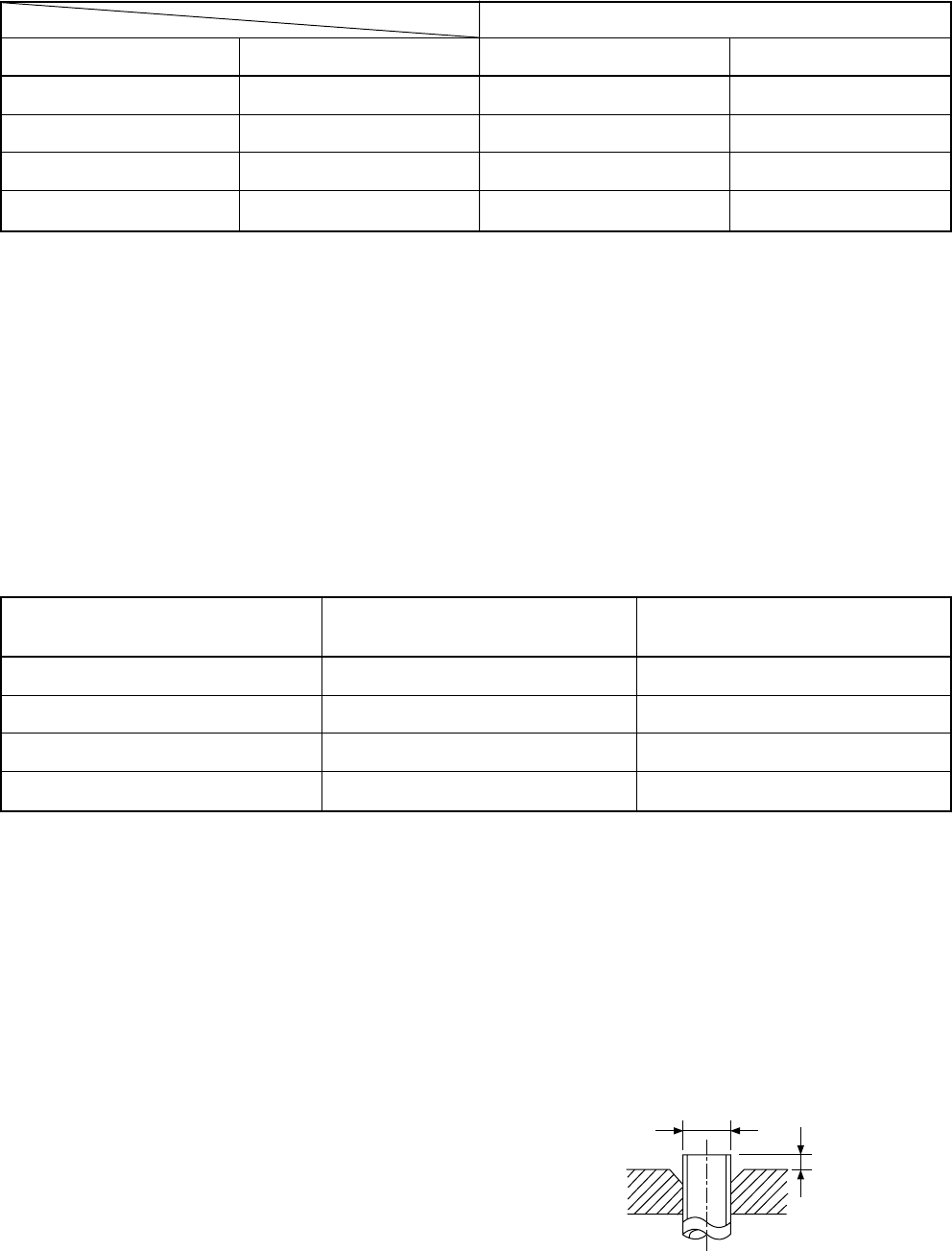

d) Flare processing

Make certain that a clamp bar and copper pipe

have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conven-

tional flare tool.

Flare processing dimensions differ according to

the type of flare tool. When using a conven-

tional flare tool, be sure to secure “dimension A”

by using a gauge for size adjustment.

Fig. 6-2-1 Flare processing dimensions

6-2-1. Processing of piping materials

When performing the refrigerant piping installation,

care should be taken to ensure that water or dust does

not enter the pipe interior, that no other oil other than

lubricating oils used in the installed air conditioner is

used, and that refrigerant does not leak. When using

lubricating oils in the piping processing, use such

lubricating oils whose water content has been removed.

When stored, be sure to seal the container with an

airtight cap or any other cover.

(1) Flare Processing procedures and precautions

a) Cutting the pipe

By means of a pipe cutter, slowly cut the pipe

so that it is not deformed.

b) Removing burrs and chips

If the flared section has chips or burrs,

refrigerant leakage may occur. Carefully

remove all burrs and clean the cut surface

before installation.

c) Insertion of flare nut

∅D

A