– 43 –

PRE.DFILTERHi POWER

9-10. FINAL INSTALLATION CHECKS

9-10-1. Precautions

Ensure that the electrical cable used for power supply

and control of the system is unable to come into

contact with either service valves or piping work which

are not insulated.

9-10-2. Electrical wiring

When installation is complete, check that all power

supply and interconnecting wiring has been

appropriately protected.

9-10-3. Refrigerant piping

When refrigerant and drain piping have been

completed. Ensure that all pipework is fully insulated

and apply finishing tape to seal the insulation.

9-10-4. Check and Test Operation

• Pressure of R410A is approx. 1.6 times of that of

R22. If installation work is incompletely finished, a

gas leakage may occur at the cases such as

pressure rise during operation.

Therefore, be sure to test the piping connections for

leakage.

• Check the flare nut connections, valve stem cap

connections and service port cap fittings for gas

leak with a leak detector or soap water.

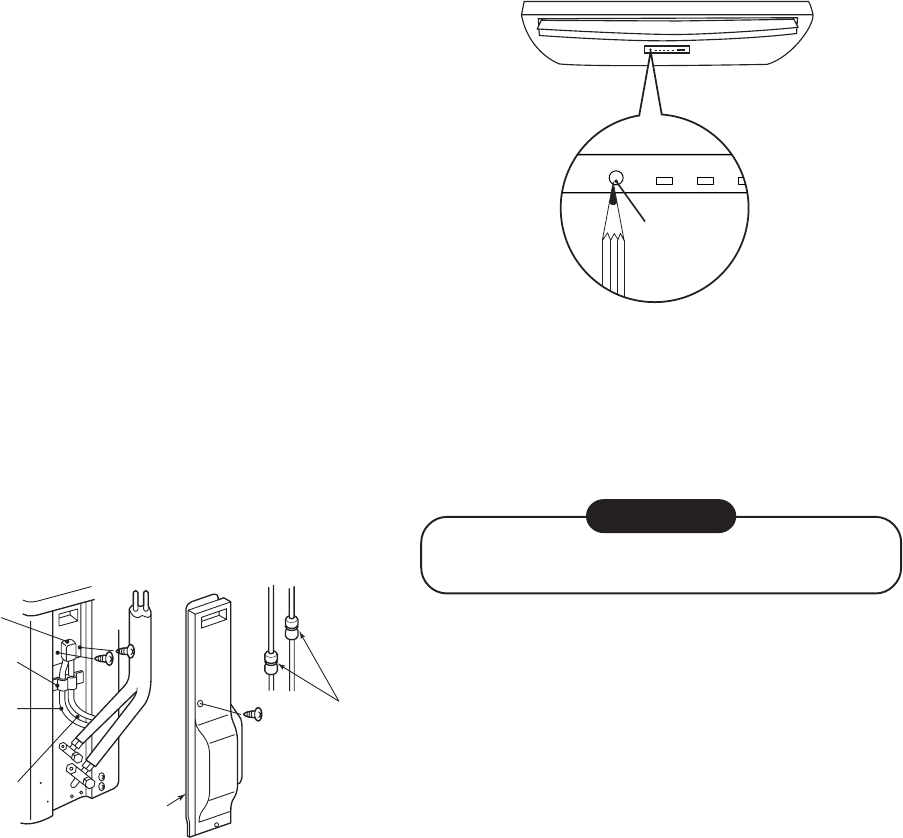

Fig. 9-10-1

Flare nut

connections

(Indoor unit)

Piping cover

Cord clamp

Indoor/Outdoor

connecting

cables

Power cable

Valve cover

9-10-5. Test Operation

To switch the TEST RUN (COOL) mode, press

TEMPORARY button for 10 sec.

(The beeper will make a short beep.)

Fig. 9-10-2

TEMPORARY

button

9-10-6. Auto Restart Setting

This product is designed so that, after a power failure,

it can restart automatically in the same operating

mode as before the power failure.

Information

The product was shipped with Auto Restart

function in the off position. Turn it on as required.

<How to set the Auto Restart>

• Press and hold the TEMPORARY button for about

3 seconds. After 3 seconds, the electronic beeper

makes three short beeps to tell you the Auto Restart

has been selected.

• To cancel the Auto Restart, follow the steps

described in the section Auto Restart Function of

the Owner’s Manual.