– 30 –

CAUTION

• KEEP IMPORTANT 4 POINTS FOR INSTAL-

LATION (PIPING WORK)

(1) Take away dust and moisture (Inside of the

connecting pipes.)

(2) Tight connection (between pipes and unit)

(3) Evacuate the air in the connecting pipes using

VACUUM PUMP.

(4) Check gas leak (connected points)

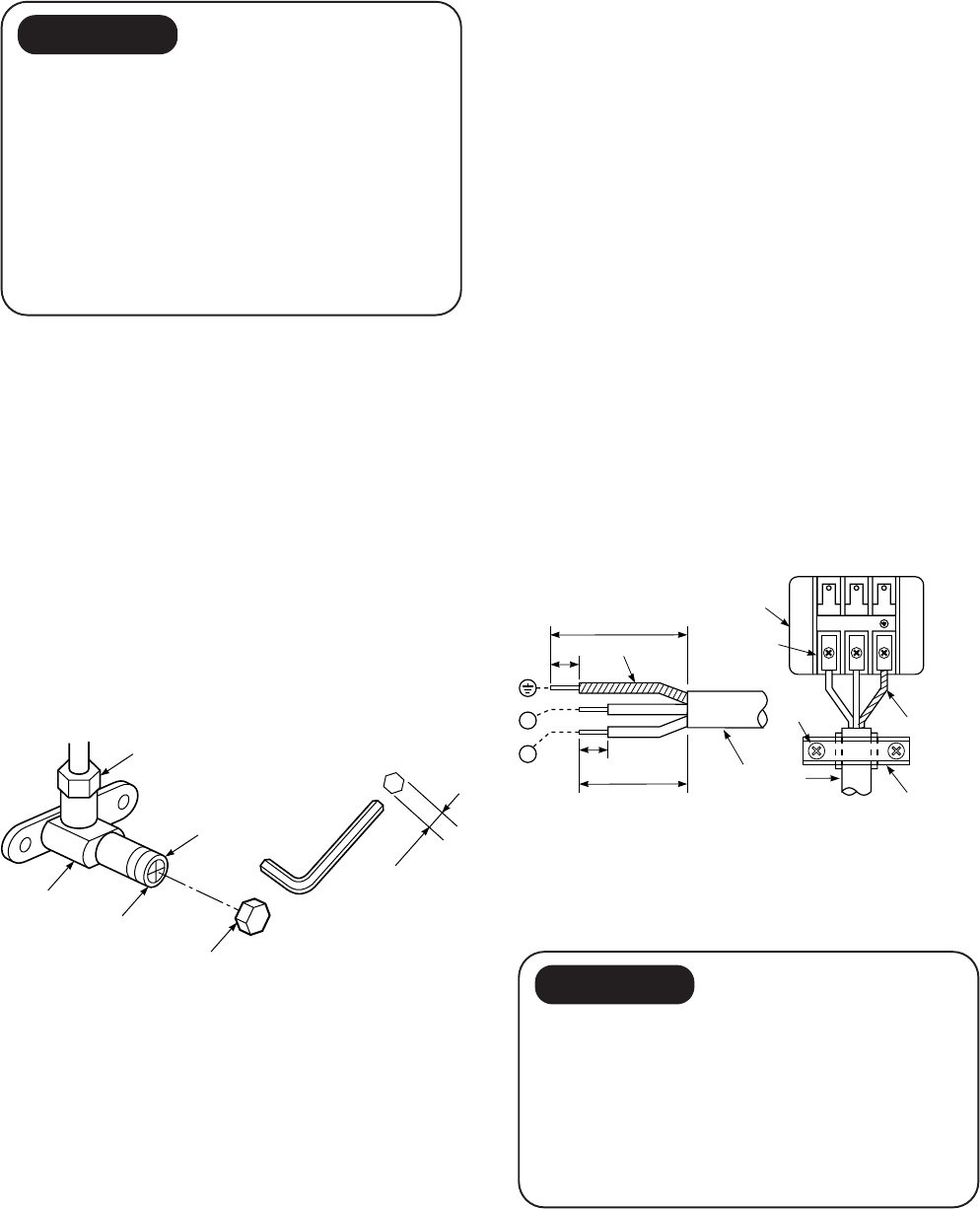

<Packed Valve Handling Precautions>

• Open the valve stem all the way out; so not try to

open it beyond the stopper.

• Securely tighten the valve stem cap with the

wrench or like.

• Valve stem cap tightening torque is as follows;

Gas pipes side (ø9.52) : 29.4 N•m (3.0 kgf•m)

Liquid pipe side (ø6.35) : 16.2 N•m (1.7 kgf•m)

<A5 mm hexagon wrench is required.>

8-5-3. Wiring Connection

(1) Remove the electric parts cover from the outdoor

unit. (1 screw)

(2) Connect the connecting cable to the terminals as

identified with their respective matched numbers

on the terminal block of indoor and outdoor units.

(Strip the sheath of connecting cable with following

stripping length to and insert into the terminal

block.)

(3) When connecting the connecting cable to outdoor

unit terminal, make a loop as shown in the

installation diagram of indoor and outdoor unit, to

prevent water coming in the outdoor unit.

(4) Insulate the unused cords (conductors) with water

coming in the outdoor unit. Process them so that

they do not touch any electrical or metal parts.

<Stripping length of connecting cable>

Fig. 8-5-6

5mm

Flare nut

Stopper

Valve body

Valve stem

Valve stem cap

60mm

1

12

10mm

10mm

50mm

Connecting

cable

Screw

Terminal block

Terminal

screw

Cord clamp

Earth line

2

Earth line

For a three conductor cable

Fig. 8-5-7

CAUTION

• Wrong wiring connections may cause some

electrical parts to burn out.

• Be sure to comply with local code on running

the wire from the indoor unit to outdoor unit.

(size of wire and wiring method etc.)

• Every wire must be connected firmly.

NOTE :

• Wipe type : More than H05 RN-F