11

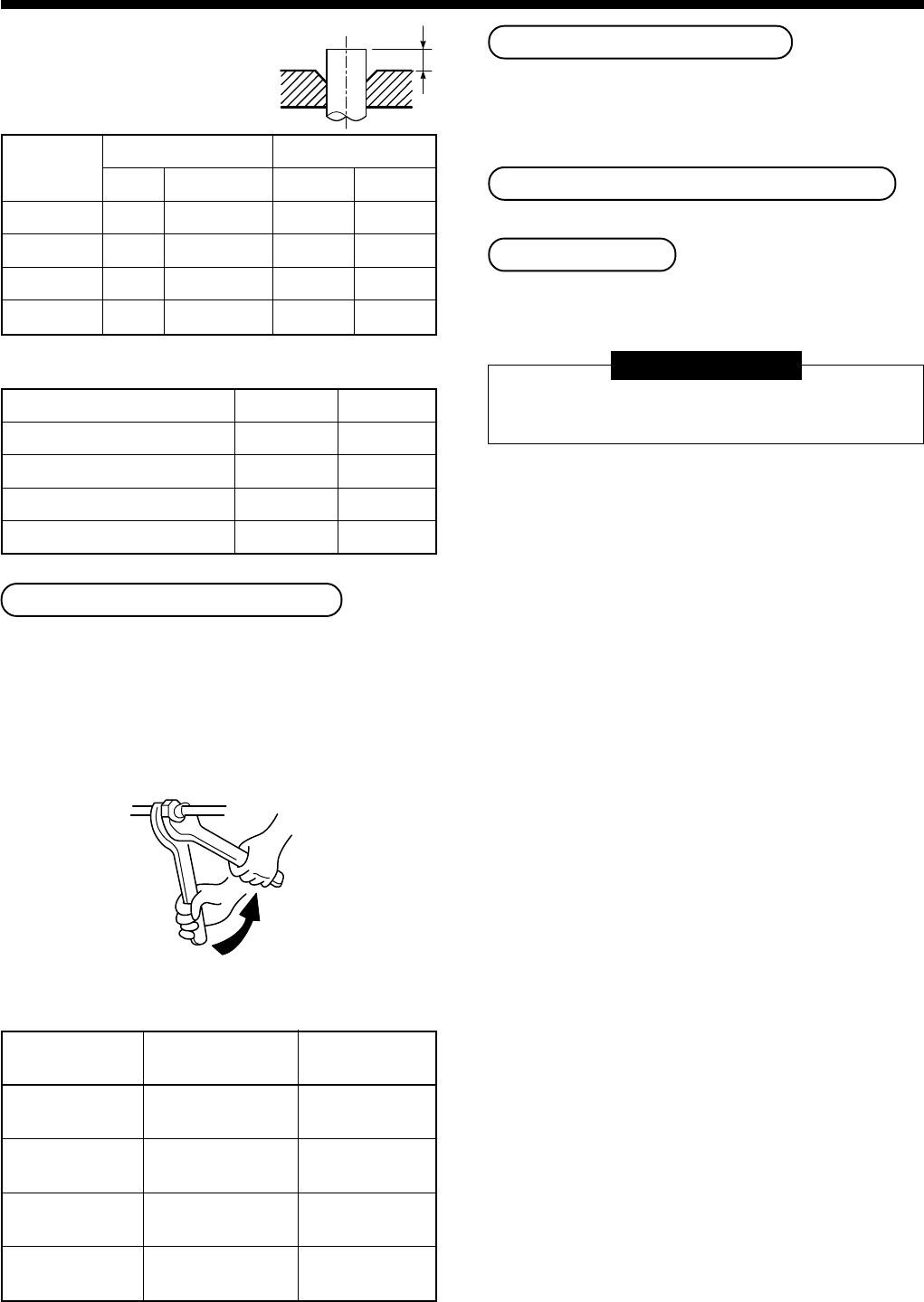

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

Imperial (Wing nut type)

Connection of refrigerant pipe

Connect all the refrigerant pipes with flare connecting

work.

• Since the atmospheric pressure only is sealed as the

sealing gas, it is not abnormal that “Pushu…” sound

is not heard when the flare nut is removed.

• Be sure to use a double spanner for pipe connecting

work of the indoor unit.

• Refer to the following table for tightening torque.

Connecting pipe

outer dia. (mm)

Ø6.4

Ø9.5

Ø12.7

Ø15.9

Tightening torque

(N•m)

14 to 18

(1.4 to 1.8 kgf•m)

33 to 42

(3.3 to 4.2 kgf•m)

50 to 62

(5.0 to 6.2 kgf•m)

68 to 82

(6.8 to 8.2 kgf•m)

Re-tightening

torque (N•m)

18

(1.8 kgf•m)

42

(4.2 kgf•m)

50

(5.0 kgf•m)

68

(6.8 kgf•m)

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant, and

gas leak check, follow the Installation Manual attached

to the outdoor unit.

Open fully valves of the outdoor unit

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap

of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for

HFC refrigerant (R410A, R134a, etc.).

Outer diam. of

copper pipe

6.4

9.5

12.7

15.9

R410A tool used

R410A R22

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

B

Work using double spanner

8

REFRIGERANT PIPING