NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

7

The gas control valve is located in the lower

control compartment. To access the valve open

the lower control compartment door (

Figure

13

). The control valve has a ³⁄₈" NPT thread inlet

port and is fitted with a 3" (76 mm) long nipple,

³⁄₈" NPT on both ends. Plan the connections

accordingly.

D. When the gas lines are tested and leak free,

observe the individual tongues of flame on the

burner. Make sure all ports are open and pro-

ducing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean

out the ports.

An external regulator must be used on all pro-

pane (L.P.G.) heaters, in addition to the regula-

tor within the gas valve, to reduce the supply

tank pressure to 13" w.c. (maximum).

WARNING: CONNECTING DIRECTLY TO

AN UNREGULATED PROPANE TANK CAN

CAUSE AN EXPLOSION.

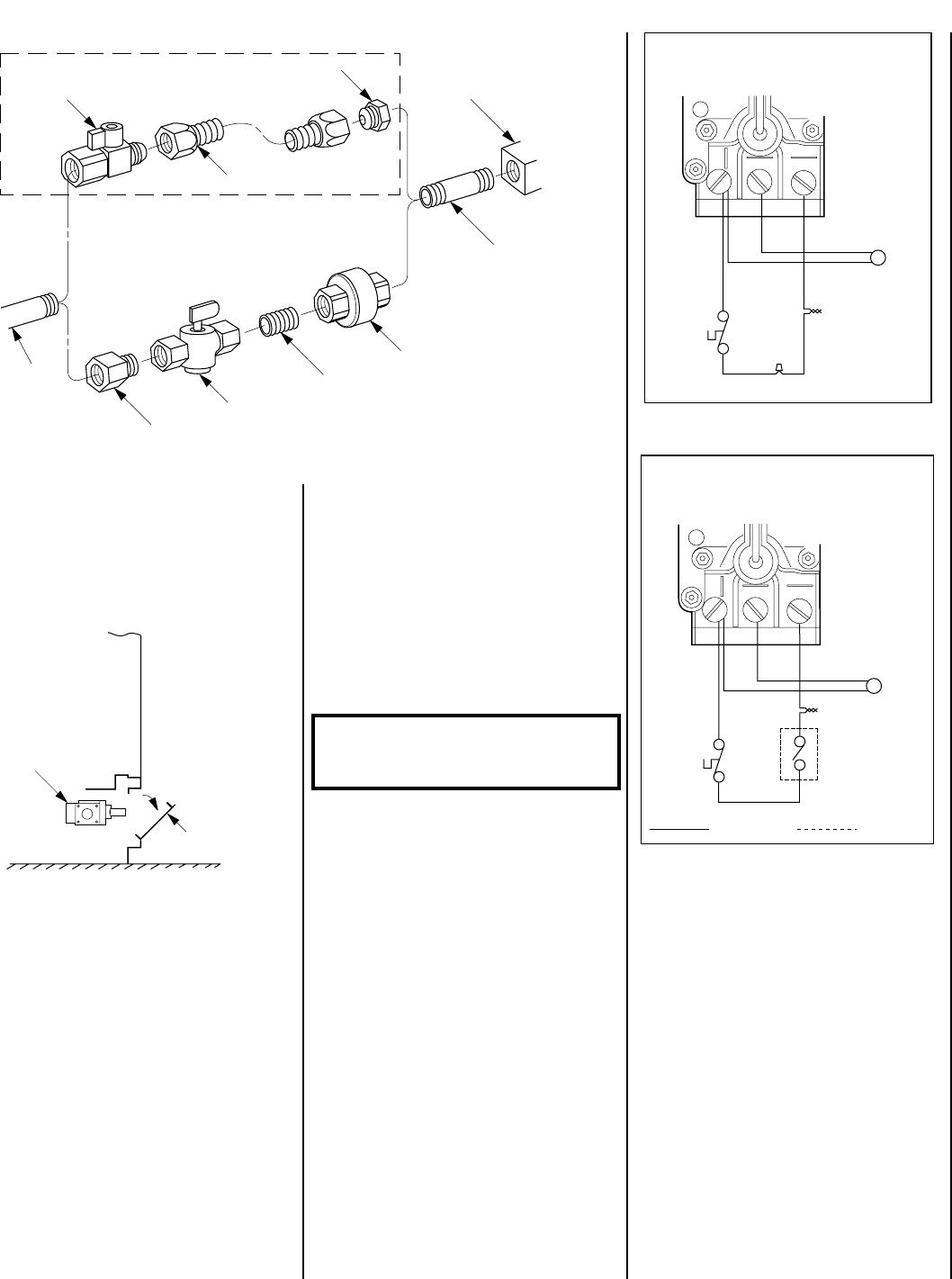

Step 6. Wiring – The wiring diagram is detailed

in

Figure 14

. Refer to

Figure 15

to field wire

optional wall switch. All electrical wiring must

be in accordance with local codes or, in the

absence of local codes the latest edition of the

National Electrical Code, ANSI/NFPA 70. The

heater must be electrically grounded.

Step 7. Installing the Optional Remote Wall

Switch – The standard millivolt system comes

from the factory wired as shown in

Figure 14

.

Select a convenient location for the remote wall

switch and connect the wiring to the appliance

(

Figure 15

).

CAUTION: DO NOT CONNECT THE OP-

TIONAL REMOTE SWITCH TO A 120V

POWER SUPPLY.

Note: The optional rocker switch is mounted to

the appliance and wired in the same way as the

remote wall switch.

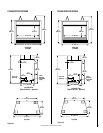

Figure 12

Control

Valve

Lower Control

Compartment Door

Figure 15

Standard Wiring Diagram

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 105°C – 18 GA. wire.

Door

Switch

Thermopile

TPTH TP TH

Red

Wht

Red

Blu

* For On/Off Switch Attachment.

*

Blk

Blk

Optional Wiring Diagram

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 105°C – 18 GA. wire.

Optional

ON/OFF

Rocker

Switch

Door

Switch

Thermopile

TPTH TP TH

Red

Blk

Wht

Red

Blu

Factory Wired

Field Wired

Figure 14

Step 8. Installing the Optional Forced Air Blower

Kit Wiring – An electrical outlet box is provided

for the installation of the FAB-1100 forced air

blower kit (optional). Electrical power must be

provided to this box to operate the blower.

Route a 3-wire, 120Vac power line with control

switch to the lower right rear corner of the

appliance. Make connections to the receptacle as

shown in

Figure 16

.

IMPORTANT: Ground lead must be connected

to the green screw located on the junction box

cover plate. Failure to do so will prevent the

appliance from operating. The appliance must

be electrically grounded in accordance with local

codes or, in the absence of local codes, the

National Electrical Code, ANSI/NFPA 70- latest

edition. (In Canada, the current CSA C22-1 Cana-

dian Electrical Code.)

Gas Stub

¹₂" x ³₈" Flare

Shut-Off Valve

³₈" Flex Tubing

³₈" NPT x ³₈"

Flare Fitting

³₈" Nipple, Standard

with all Units

³₈" Union

³₈" Close Nipple

³₈" Shut-Off Valve

¹₂" x ³₈" Reducer

Gas Valve

Gas Flex Line Kit, Model GFLV

Figure 13

Secure all joints tightly using appropriate tools

and sealing compounds (ensure propane resis-

tant compounds are used in propane applica-

tions). Turn on gas supply and test for gas leaks

using a soapy water solution. Never use an

open flame to check for leaks.

A. Mix a 50% dish soap, 50% water solution.

B. Light the appliance (refer to safety and

lighting instructions on page 17).

C. Brush all joints and connections with the

soapy water solution to check for leaks. If

bubbles are formed, or gas odor is detected,

turn the gas control knob to the “OFF” position.

Either tighten or refasten the leaking connec-

tion and retest as described above.