356214-XIM-A-0108

16 Johnson Controls Unitary Products

For satisfactory operation, L.P./propane gas pressure

must be 10.0 I.W.C. at the unit manifold under full load.

Maintaining proper gas pressure depends on three

main factors:

1. The vaporization rate depends on (a) the tempera-

ture of the liquid and (b) the "wetted surface" area

of the container or containers.

2. The proper pressure regulation. (Two-stage regula-

tion is recommended from the standpoint of both

cost and efficiency.)

3. The pressure drop in the lines between regulators

and between the second stage regulator and the

appliance. Pipe size required will depend on the

length of the pipe run and the total load of all appli-

ances.

Complete information regarding tank sizing for vapor-

ization, recommended regulator settings, and pipe siz-

ing is available from most regulator manufacturers and

L.P./propane gas suppliers.

L.P./propane gas is an excellent solvent and special

pipe compound must be used when assembling piping

for this gas as it will quickly dissolve white lead or most

standard commercial compounds. Shellac base com-

pounds such as Rectorseal #5 are satisfactory for this

type of gas.

Check all connections for leaks when piping is com-

pleted, using a soap solution. NEVER USE A FLAME.

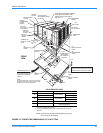

VENT AND COMBUSTION AIR HOODS

Two vent hoods and a combustion air hood (with

screens) are shipped attached to the blower housing in

the blower compartment. These hoods must be

installed to assure proper unit function. All hoods must

be fastened to the outside of the gas heat access panel

with the screws provided in the bag also attached to

the blower housing.

The screen for the combustion air intake hood is

secured to the inside of the access panel opening with

four fasteners and the screws used for mounting the

hood to the panel. The top flange of this hood slips in

under the top of the access panel opening when install-

ing. Refer to Vent and Combustion Air Hood Figure 8.

Each vent hood is installed by inserting the top flange

of the hood into the slotted opening in the access panel

and securing in place.

The products of combustion are discharged horizon-

tally through these two screened, hooded vent open-

ings on the upper gas heat access panel.

OPTIONAL ECONOMIZER/MOTORIZED DAMPER RAIN

HOOD

The instruction for the optional economizer/motorized

damper rain hood can be found in the kit. Use these

instructions when field assembling an economizer rain

hood onto a unit. The outdoor and return air dampers,

the damper actuator, the damper linkage, the outdoor

and return air divider baffles, and all the control sen-

sors are factory mounted as part of the "Factory

installed" economizer option.

FIRE OR EXPLOSION HAZARD

FAILURE TO FOLLOW THE SAFETY WARN-

ING EXACTLY COULD RESULT IN SERIOUS

INJURY, DEATH OR PROPERTY DAMAGE.

NEVER TEST FOR GAS LEAKS WITH AN

OPEN FLAME. USE A COMMERICALLY

AVAILABLE SOAP SOLUTION MADE SPE-

CIFICALLY FOR THE DETECTION OF

LEAKS TO CHECK ALL CONNECTIONS. A

FIRE OR EXPLOSION MAY RESULT CAUS-

ING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

FIGURE 8 - VENT AND COMBUSTION AIR HOOD

VENT AIR

OUTLET

HOODS

SLOTTED

OPENINGS IN

ACCESS PANEL

COMBUSTION

A

IR INTAKE

HOOD

GAS HEAT

ACCESS

PANELS