Dehumidifying Dryers Chapter 5: Maintenance 43 of 59

Cleaning with Compressed Air

Blow clean, dry compressed air up and down the pleats, blowing out the filter

from the inside out. Remove loose dirt from the filter with compressed air or

vaccum from the outside.

Caution! DO NOT clean/wash filter with water!

After each cleaning:

• Inspect the filter element. Briefly hold a light bulb behind the element

and look for any fatigued paper or residual dirt. Inspect for holes and

tears by looking though the filter toward a bright light. Check for

damaged gaskets or dented metal parts. Do not re-use a damaged

filter!

• Check the gasket for damage. A damaged gasket allows contaminants

into the process. Replace as needed.

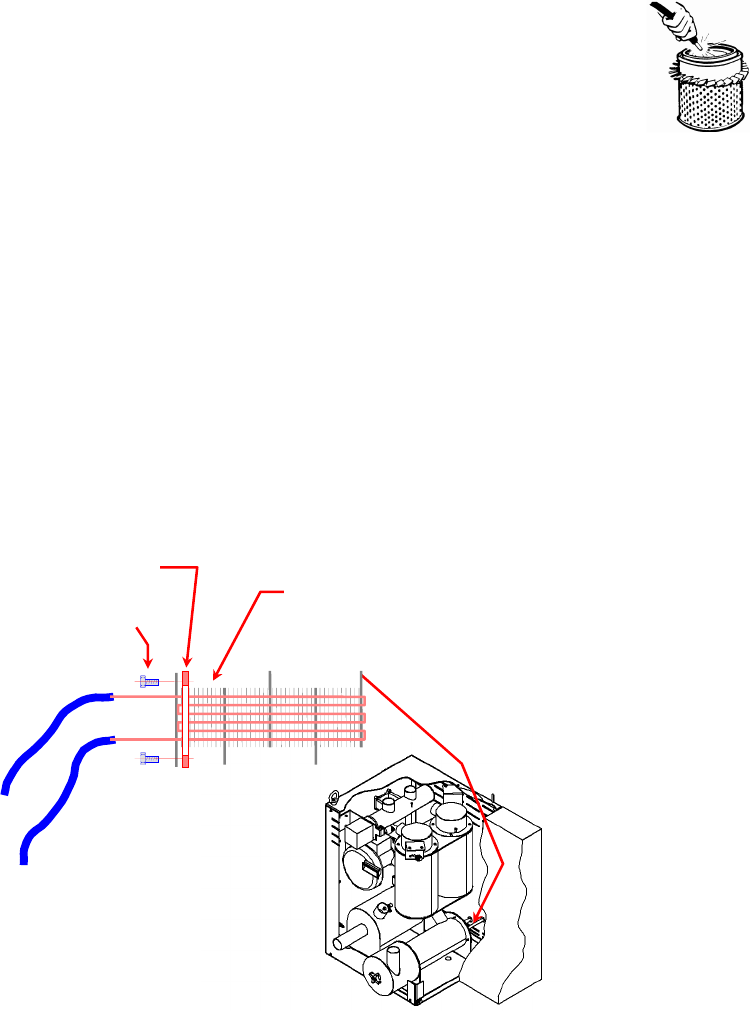

Figure ?: Cooling Coil Location and Disassembly

Note: To clean the cooling coil, use compressed air or a steam cleaner to blow the

dust off or clean any oily residue on the coil.

Servicing the Dew Point Monitor

The accuracy of the dew point monitor on mini dryer systems depends on proper operation of

the dew point sensor and the control board. The dew point sensor is in the process air stream

and is therefore susceptible to contamination.

Undo (4) 10-32 Button

Head Screws using 1/8

Allen Wrench

Use compressed air or a steam

cleaner to blow the dust off or clean

any oily residue on the coil.

1" Wide x 1/8" Thick High

Temperature Gasket