Dehumidifying Dryers Chapter 3: Installation 21 of 59

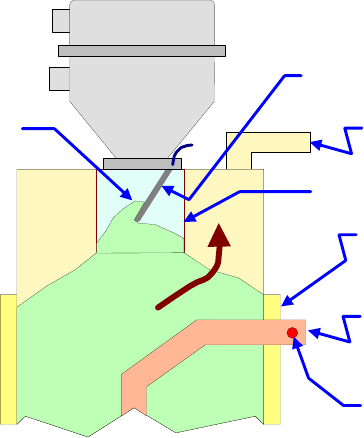

Drying Hopper Air Trap Considerations

Our exclusive air trap assembly on the top of the drying hopper prevents ambient air from

contaminating the material being dried. To ensure that your unit will operate at peak

efficiency, do the following:

• Keep the material level at the mid point of the air trap

• This can be achieved by utilizing a hopper loader or vacuum conveying system to

supply material to the drying system.

Figure 1: Drying Hopper Air Trap

Optional Aftercooler

Water-cooled 15/30/60 cfm models use a water-to-air heat exchanger as an aftercooler.

Cooling water is required for this design (3 gpm at 85°F or lower). Return air from the

hopper passes through the air filter to trap fines and dust before entering the heat exchanger.

Installing Water Lines

(Hose and Hose Clamp)

When installing the water lines, ensure that the aftercooler utilizes either tower, chilled or city

water as warm as 85°F (29°C). Recommended flow rate is three (3 gpm) gallons per minute

(11 liters per minute).

Suggested material level

for the optimum

efficiency.

Air Trap

Flapper Valve

of the loader

Return air from the

drying hopper.

Delivery low dew point,

heated air to the drying

hopper.

Insulation

Recommended process

temperature control

thermocouple location.