Dehumidifying Dryers Chapter 2: Functional Description 11 of 59

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for 15, 30, and 60

cfm dehumidifying dryers. Model numbers are listed on the serial tag. Make sure you know

the model and serial number of your equipment before contacting the manufacturer for parts

or service.

Our dehumidifying mini dryers are designed to generate heated dehumidified air at carefully

controlled temperatures for use in plastic drying systems. Drying systems are sized to meet

the specific requirements stated by the Customer at the time of purchase.

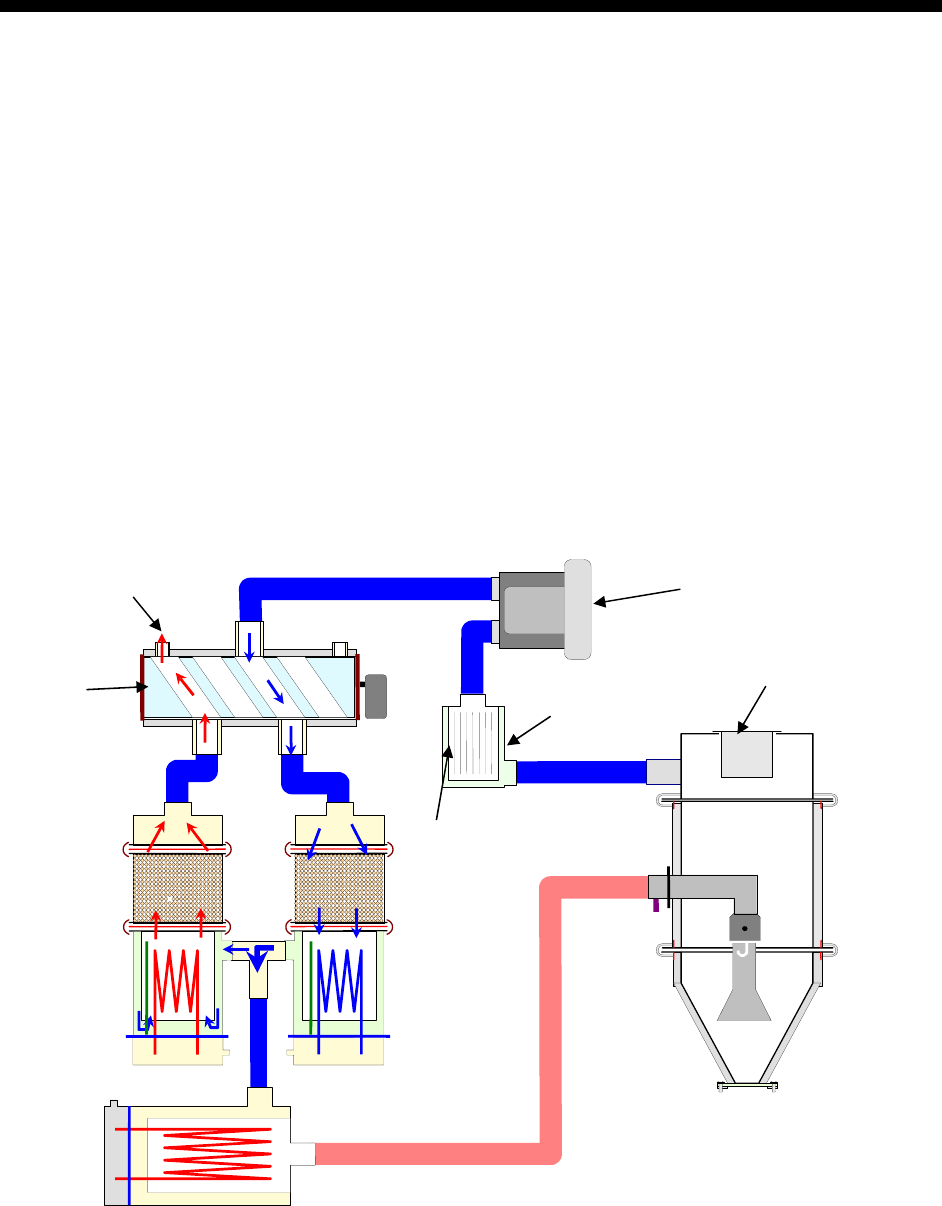

2-2 General Description

Dehumidifying dryers are used to generate very low dew point air heated to a controlled

temperature for drying plastic pellets and regrind.

Our dryers force hot, dry air through resin in a drying hopper, where air picks up moisture

from the material and draws it back to the dryer. In the dryer, a desiccant bed strips moisture

from the air. The dried process air is then re-heated and delivered back into the drying

hopper to continue to remove moisture.

Figure 15: Typical Dryer Air Flow Schematic

Drying Hopper

Valve

Moisture

Exhaust

Filter (Separates

Dust)

A

mbient

Air Flow

High pressure

prepheral blower