BP1620, BP1628 & BP1640 Granulators Page 39 BP1600

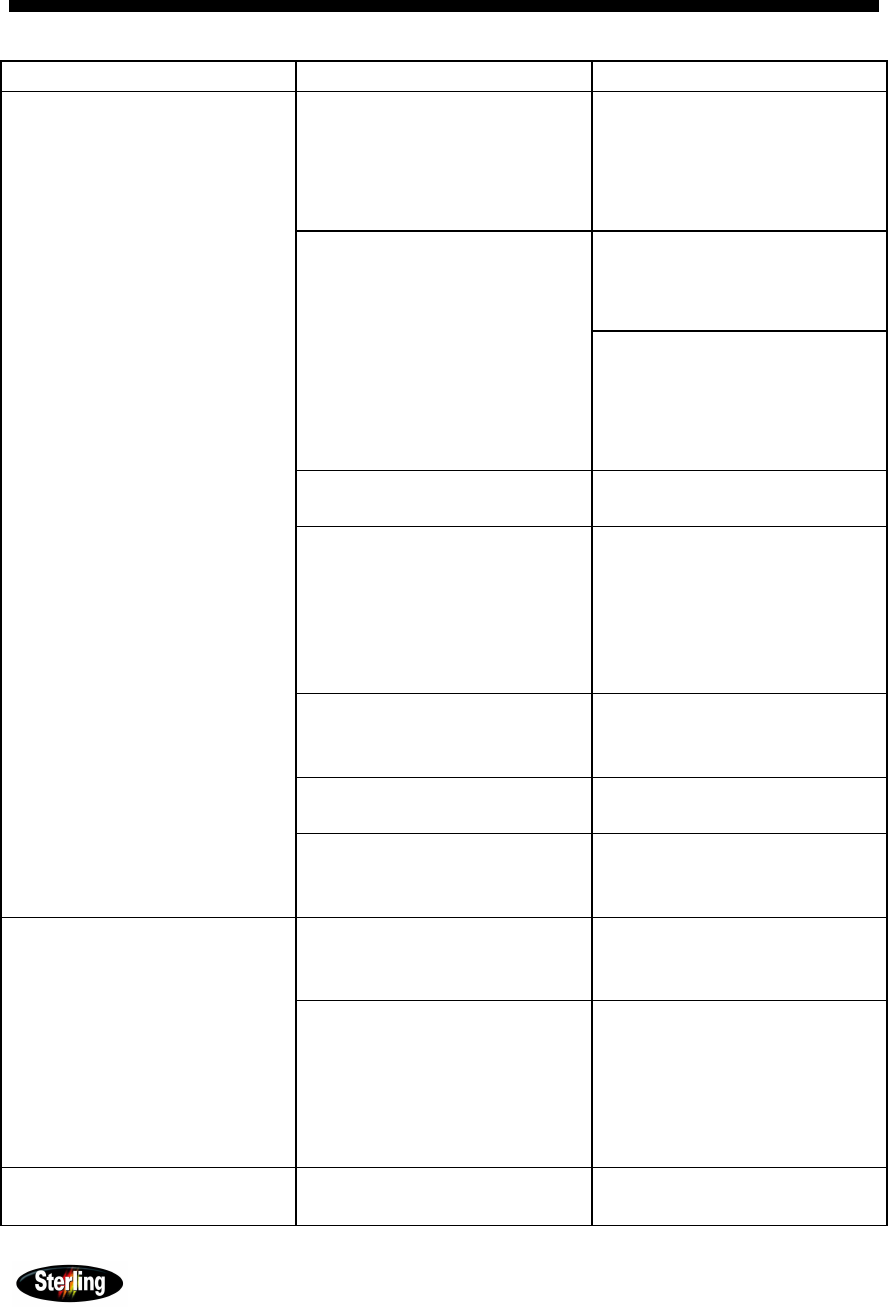

10 Troubleshooting

Problem Possible Cause Solution

No power.

Verify that the correct

pushbuttons are being

depressed and that the

main disconnect switch is

in the ON position.

Try to locate grounds, a

locked rotor or other

reasons.

Fuses are blown.

Replace fuses with the

size and type shown on

the wiring diagram

(located in the control

enclosure).

Check for motor and fan

overloads.

If required, reset #1

MOL, #2 MOL.

If a limit switch is open.

Check the limit switches

at the cutting chamber,

screen chamber, and

hopper cleanout doors.

Ensure proper actuation

and replace if required.

If fan is hinged type

design (optional)

Check safety limit switch

to be sure it is making

contact.

If not equipped with fan

Check jumper on

terminals #3 & #5.

Motor/(optional) fan

motor will not start.

After completing above

inspection, machine will

still not start.

Call Service Department.

Machine is overloaded

with feedstock.

Reduce amount of

feedstock put into

machine per unit of time.

Machine stalls/(optional)

fan stalls

Pieces of feedstock

jammed in the rotor.

Clear the jammed

material then visually

inspect the rotor to

ensure it is not damaged

and that the knife gaps

are correct.

Problem

Possible Cause Solution