BP1620, BP1628 & BP1640 Granulators Page 38 BP1600

7. After the clearance setting of both the primary and

secondary bed knives is complete and checked, turn the

rotor by hand to ensure that none of the rotor knives hit

the bed knives.

8. Double check inside the machine to make sure no tools

or other articles are left in the cutting chamber or have

fallen into the screen area.

9. Close the cutting chamber and tighten the fasteners

(refer to Section 4-2).

9-9 Preventative Maintenance Service

Follow a systematic preventative maintenance program to

help avoid costly down time. Call the Sterling Service

Department to arrange a schedule of inspections. This

service can be tailored to fit your maintenance

requirements.

9-10 Recommended Torque For Knife Bolts

NOTE: For Rotor knife applications, use Grade 10.9 ad cap screws.

For Bed knife applications, use Grade 10.9 hex head

screws.

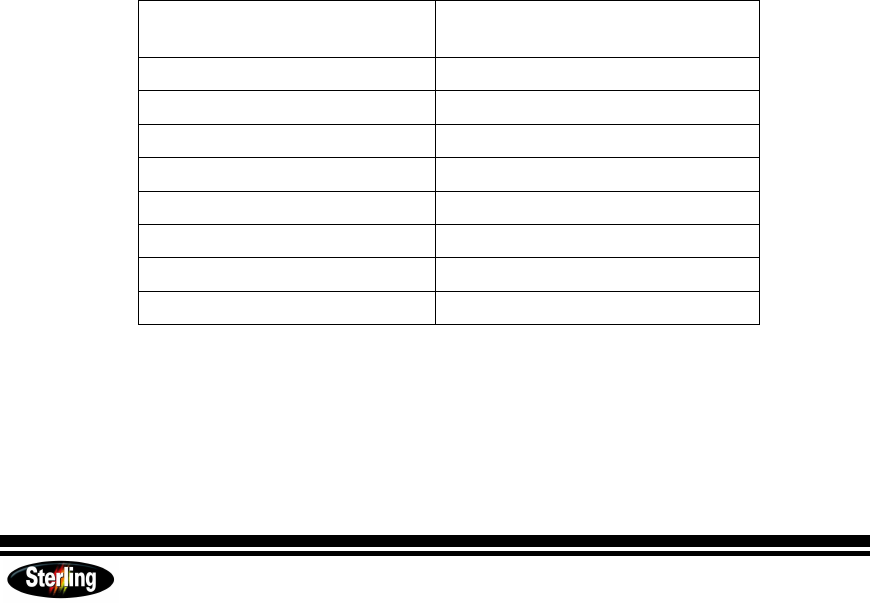

Table 6

Recommended Bolt Torques (Metric)

METRIC SCREW SIZE

FT/LBS TORQUE

(DRY)

M8 28

M10 54

M12 100

M14 155

M16 232

M18 340

M20 472

M24 610

**The above listed torque values are standard specifications.

***Metric Knife Bolt/Screw Tightening Torque for Grade 10.9 Fine Thread