Large Dehumidifying Dryers Mechanical Installation 27

; Make sure all electrical connections are tight.

3-4 Making Gas Line Connections (Gas-Fired Models Only)

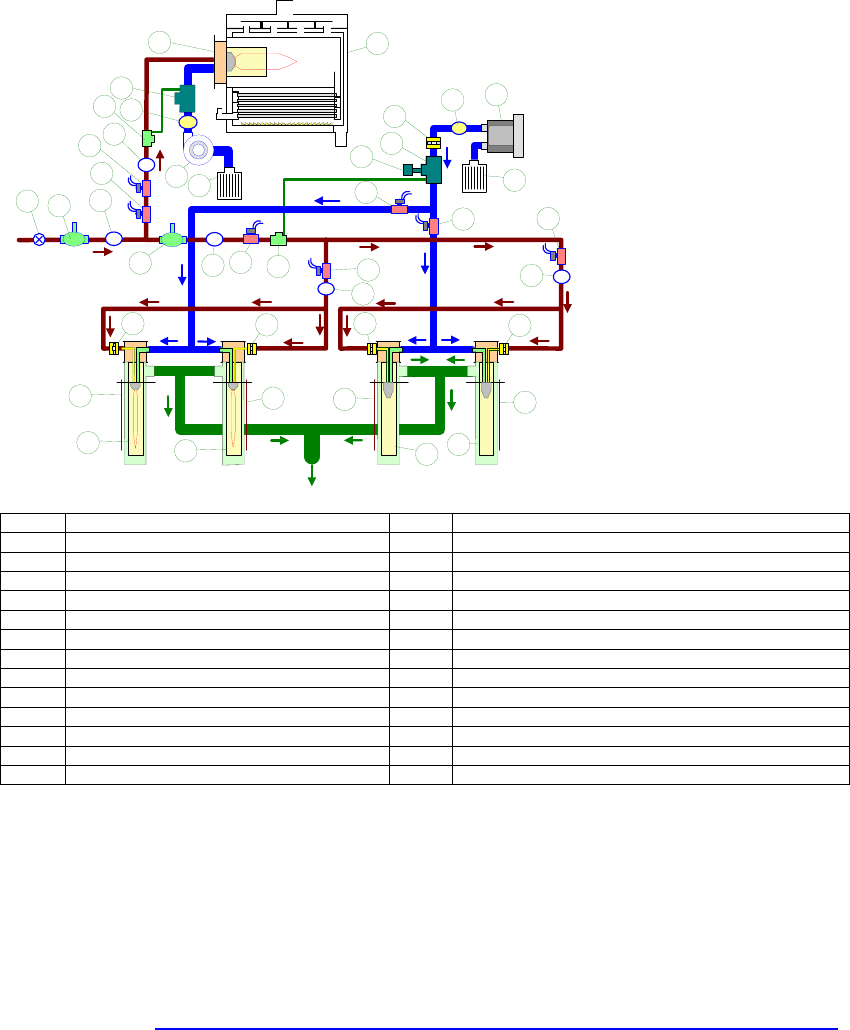

Connect a gas line to the dryer’s gas inlet. See Figure 6 for a detailed schematic of the gas

system.

Figure 6: Gas Flow Schematic

PS

Fume

Exhaust

PS

PS

C

B

1

2

3

4

4

6

7

8

9

10

11

12

13

14

3

16

17

16

PS

3

20

21

22

21

21

21

20

20

20

22

22

22

16

3

23

24

25

PS

PS

P

S

5

15

15

18

19

Gas Dryers Air

Fuel Train

Item Description Item Description

1 Manual gas shut off valve 14 Regeneration gas regulator

2 Gas regulator 15 Regeneration air solenoid valve

3 Gas pressure switch 16 Regeneration gas solenoid valve

4 Process gas solenoid valve 17 Regeneration gas proportionator

5 Manual adjustable butterfly valve 18 Regeneration butterfly orifice valve

6 Process gas proportionator 19 Regeneration air actuator

7 Process air actuator 20 Adjustable gas orifice

8 Air pressure switch 21 Regeneration thermocouple

9 Process ratiomatic burner 22 Regeneration SER burner

10 Process gas heat exchanger 23 Regeneration & combustion air filter

11 Gas pressure switch 24 Combustion air blower

12 Process combustion air blower 25 Air pressure switch

13 Process combustion air filter

DANGER! Natural gas burners are started, stopped, and monitored independently of

the dryer controls using Eclipse

TM

Bi-Flame burner controls. Read and

follow the burner control manufacturer’s operating and safety instructions

and applicable NFPA© (National Fire Protection Association) codes in

addition to your local rules and regulations. The Eclipse Bi-Flame model

6500 Dual Burner Monitoring System (instruction manual no. 826, 05/03)

should be included with the dryer. It is also available online at

http://www.eclipsenet.com/catalog/contents/Documents/08/826IM0503s.pdf