26

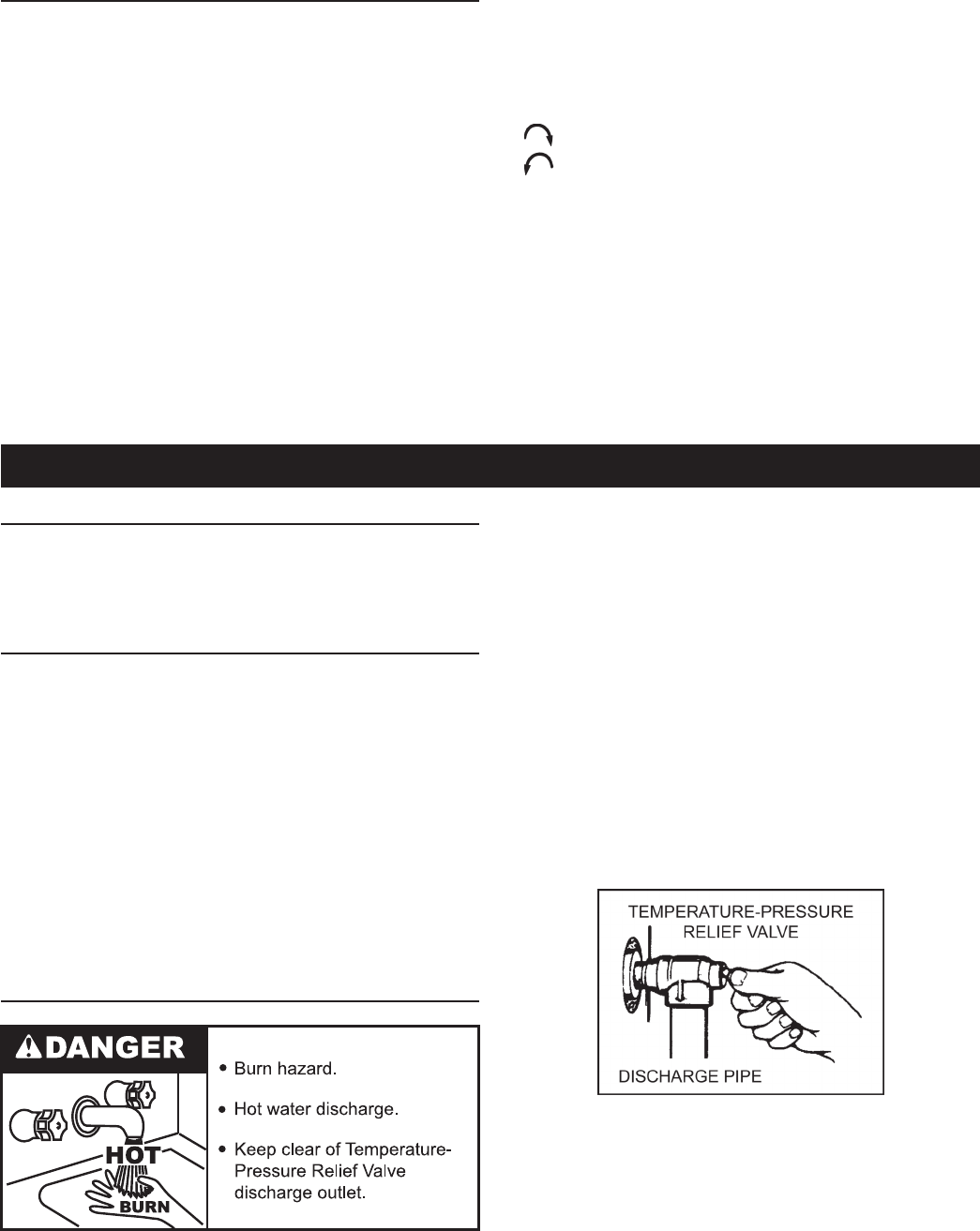

When checking the Temperature-Pressure Relief Valve operation,

make sure that (1) no one is in front of or around the outlet of the

Temperature-Pressure Relief Valve discharge line, and (2) that

the water discharge will not cause any property damage, as the

water may be extremely hot. Use care when operating valve as

the valve may be hot.

To check the relief valve, lift the lever at the end of the valve

several times, see Figure 26. The valve should seat properly and

operate freely.

If after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold water

inlet to the water heater and drain the water heater according to

the Draining and Flushing instructions on page 27. Replace the

Temperature-Pressure Relief Valve with a properly rated/sized new

one, see Temperature-Pressure Relief Valve on pages 13-14 for

instructions on replacement.

FIGURE 26

If the Temperature-Pressure Relief Valve on the water heater

weeps or discharges periodically, this may be due to thermal

expansion.

NOTE: Excessive water pressure is the most common cause of

Temperature-Pressure Relief Valve leakage. Excessive water

system pressure is most often caused by "thermal expansion"

in a "closed system." See Closed Water Systems and Thermal

CHECKING THE INPUT

For appliance installation locations with elevations above 2000

feet, refer to HIGH ALTITUDE INSTALLATIONS section of this

manual for input reduction procedure.

1. Attach a pressure gauge or a manometer to the manifold

pressure tap on the gas valve and refer to Table 3, page 8 for

correct manifold pressure.

2. Use this formula to “clock” the meter. Be sure that other gas

consuming appliances are not operating during this interval.

(3600/T) x H = Btuh

T = Time in seconds to burn one cubic foot of gas.

H = Btu’s per cubic foot of gas.

Btuh = Actual heater input.

Example: (Using SBD85500NE heater)

T = 7.56 seconds

H = 1050 Btu

Btuh = ?

(3600/7.56) X 1050 = 500,000 Btuh (Compare with the

SBD85500NE model and rating.)

Should it be necessary to adjust the gas pressure to the burners

to obtain the full input rate, the steps below should be followed:

3. Remove the regulator adjustment sealing cap, g. 25, and adjust

the pressure by turning the adjusting screw with a screwdriver.

Clockwise to increase gas pressure and input rate.

Counterclockwise to decrease gas pressure and input rate.

4. “Clock” the meter as in step 2 above.

5. Repeat steps 3 and 4 until the specied input rate is achieved.

6. Turn the gas control knob to PILOT. Remove the pressure

gauge and replace the sealing cap and the threaded plug in

the pressure tap opening.

UNDER NO CIRCUMSTANCES SHOULD THE GAS INPUT

EXCEED THE INPUT SHOWN ON THE HEATER MODEL AND

RATING PLATE. OVERFIRING COULD RESULT IN DAMAGE

OR SOOTING OF THE HEATER.

VENTING SYSTEM

Examine the venting system every six months for obstructions

and/or deterioration of the vent piping.

Remove all soot or other obstructions from chimney which will

retard free draft.

REMOTE STORAGE TANK TEMPERATURE CONTROL

The water temperature in the remote storage tank (if used) is

controlled by the storage tank temperature control. The sensing

element is mounted in the hot water storage tank, see Water

Piping Diagram section.

A change in water temperature in the storage tank lower than

the tank temperature control setting will cause the sensor to

activate the circulating pump. The pump then circulates the water

through the heater where the thermostat senses the drop in water

temperature and activates main burner operation of the appliance.

If the storage tank temperature control is out of calibration, replace

with new control.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE

TO THE APPLIANCE.

TEMPERATURE-PRESSURE RELIEF VALVE TEST

It is recommended that the Temperature-Pressure Relief Valve

should be checked to ensure that it is in operating condition every

6 months.

MAINTENANCE