GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS

Page 36

Piping For Use With Cooling Units

The boiler, when used in connection with a refrigeration

system, must be installed so the chilled medium is piped

in parallel with the boiler. Appropriate valves must be

used to prevent the chilled water from entering the boiler.

When a boiler is connected to a heating coil that may

be exposed to refrigerated air from an air handling

device, the piping system must be equipped with flow-

control valves or some other automatic means of

preventing gravity circulation of the boiler water during

the cooling cycle.

Steam Boiler Piping Connections

Table 3, contains the steam riser location schedule. Riser,

equalizer and header pipe sizes are located in Table 5.

A typical single boiler piping arrangement is shown in

Figure 95. Figures 97 & 97A contain typical piping

diagrams for steam boilers in battery. The steam piping

should be pitched so the condensate flows in the direction

of steam travel.

Table 4 Supply & Return Pipe Sizing

Boiler Model Supply Size (in) Return Size (in)

5 - 10 section 3" 3"

11 - 21 section 4" 3"

Install the Pressure Relief Valve in the 1 1/2 NPT

opening in the top of the end section opposite the gas

controls. Pipe the discharge of the Pressure Relief Valve

to prevent scalding in the event of a discharge, see

Figure 93. The discharge piping must be sized the same

as the Pressure Relief Valve outlet.

CAUTION: If the relief valve must be installed on the

same end as the gas controls, provisions to protect

the controls from water in the event of a discharge

must be made.

Locate the Theraltemeter, Low Water Cutoff Device, Hi

Limit Control and Operating Control per Figures 94 & 95.

Optional controls must be installed in accordance with the

control manufacturers instructions and Figure 94.

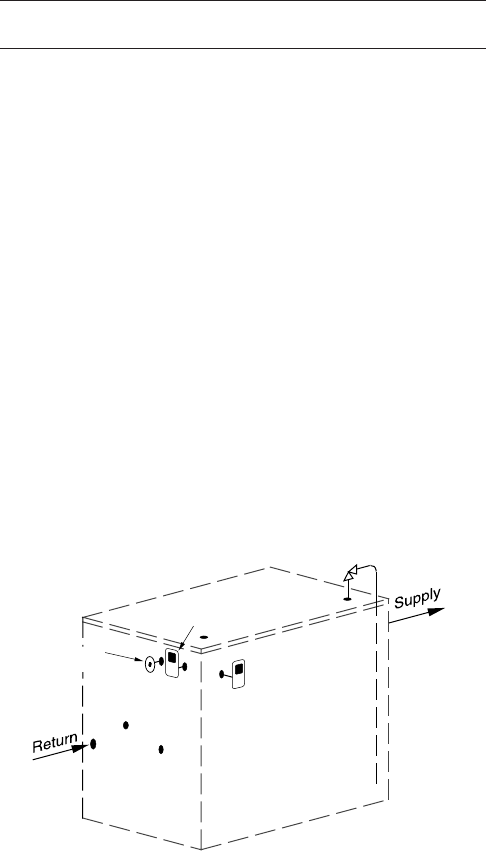

Figure 95 Single Water Boiler Piping

Hi Limit

Control

ASME

Safety

Valve

Operating

Control

Temperature

Pressure Gage