GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS

Page 19

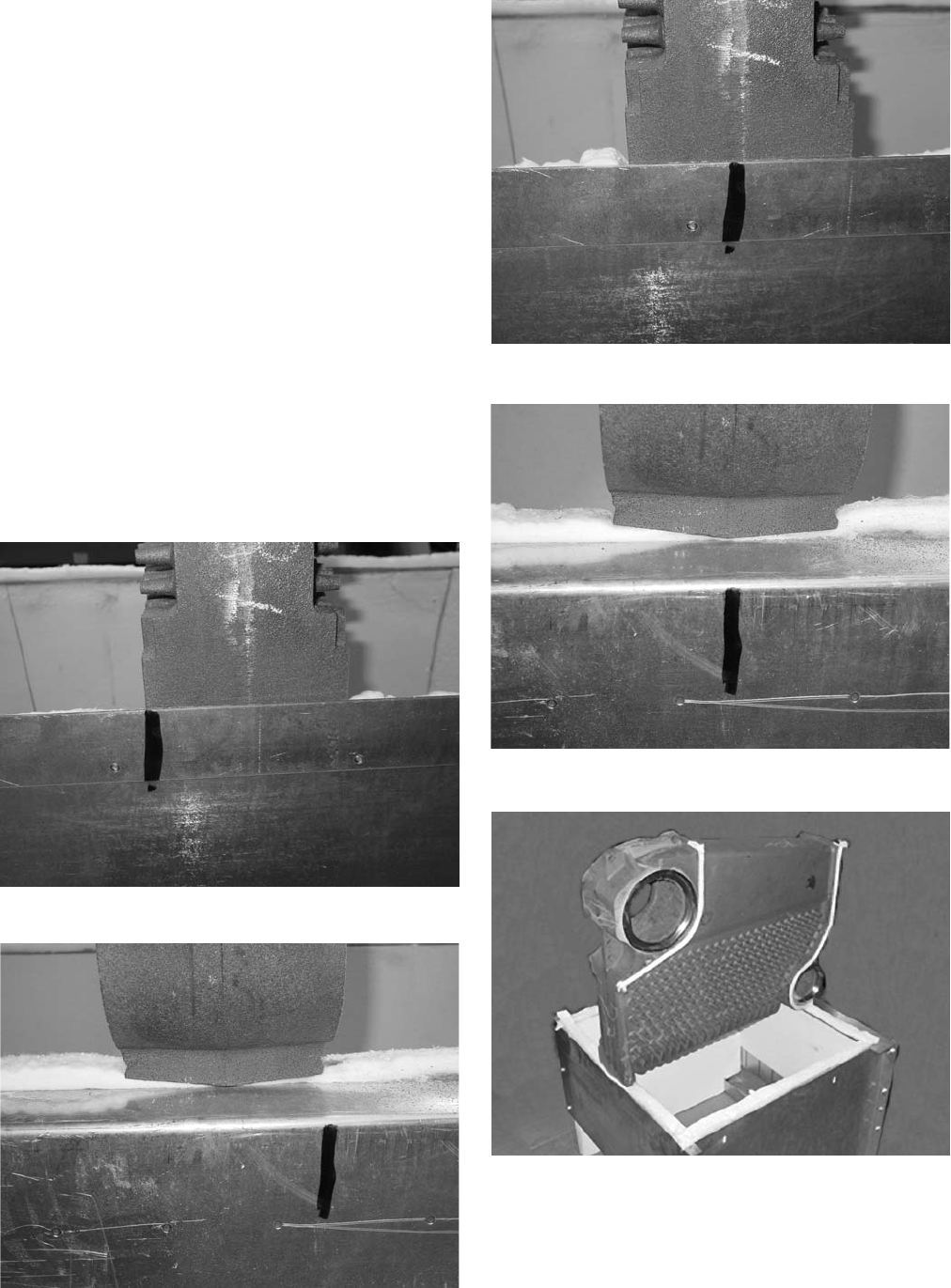

To ensure that the assembled sections will be centered

on the burner base the cast iron sections should be

assembled from the midpoint of the burner base outward.

On boilers having an even number of sections the first

intermediate section should be placed so it’s side surface

lines up with the midpoint marked on the burner base

front and rear panels, Figures 31 and 32.

For boilers having an odd number of sections, the

centerline of the first intermediate section should line up

directly with the midpoint marks on the burner base front

and rear panels, Figures 33 and 34.

Refer to Table 3 for the location of the intermediate

sections with steam riser tappings, the flue collector

brackets and the front jacket channel bracket. With the

rope seal in place set the first section on the base making

sure that the section is supported and will not fall over.

The large top port should be above the front of the burner

base, Figure 35. Set the hydronic seals from the X1 Box

in the port openings before carefully bringing the next

section along side of it, Figures 36 and 37.

Figure 31 Front View - Even Numbered Models

Figure 32 Rear View - Even Numbered Models

Figure 33 Front View - Odd Numbered Models

Figure 34 Rear View - Odd Numbered Models

Figure 35 Section Placement on Burner Base

CAUTION: Do not use adhesives or sealants on the

hydronic gaskets. The application of adhesives or

sealants may result in the failure of the hydronic

seals voiding the warranty!