GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS

Page 23

NOTE: All assembled boiler sections shall pass the

hydrostatic tests prescribed in Section IV of the

ASME Boiler and Pressure Vessel Code.

CAUTION: Do not connect any boiler controls during

the pressure test or they will be damaged!

Completed boiler blocks must be tested as follows:

Steam Boilers -

the assembled boiler sections shall be

subjected to a hydrostatic test pressure of not less than

45 psig,

315 kPa

.

Water Boilers -

the assembled boiler sections shall be

subjected to a hydrostatic test pressure of not less than

1 1/2 times the maximum allowable working pressure.

The hydrostatic pressure shall not exceed the required

test pressure by more than 10 psig,

70 kPa

during the

test.

Maintain the test pressure while carefully checking for

leaks. If a leak is found it must be eliminated. Once the

cast iron sections have proven to be watertight drain them

and remove the plugs from any tappings that will be used

in service.

FLUE COLLECTOR INSTALLATION

A single draft hood is used on the 5 through 12 section

boilers, two are used on the 13 to 21 section boilers.

The Draft Hood(s) are packed in a box marked with a

number from 63187 to 63194.

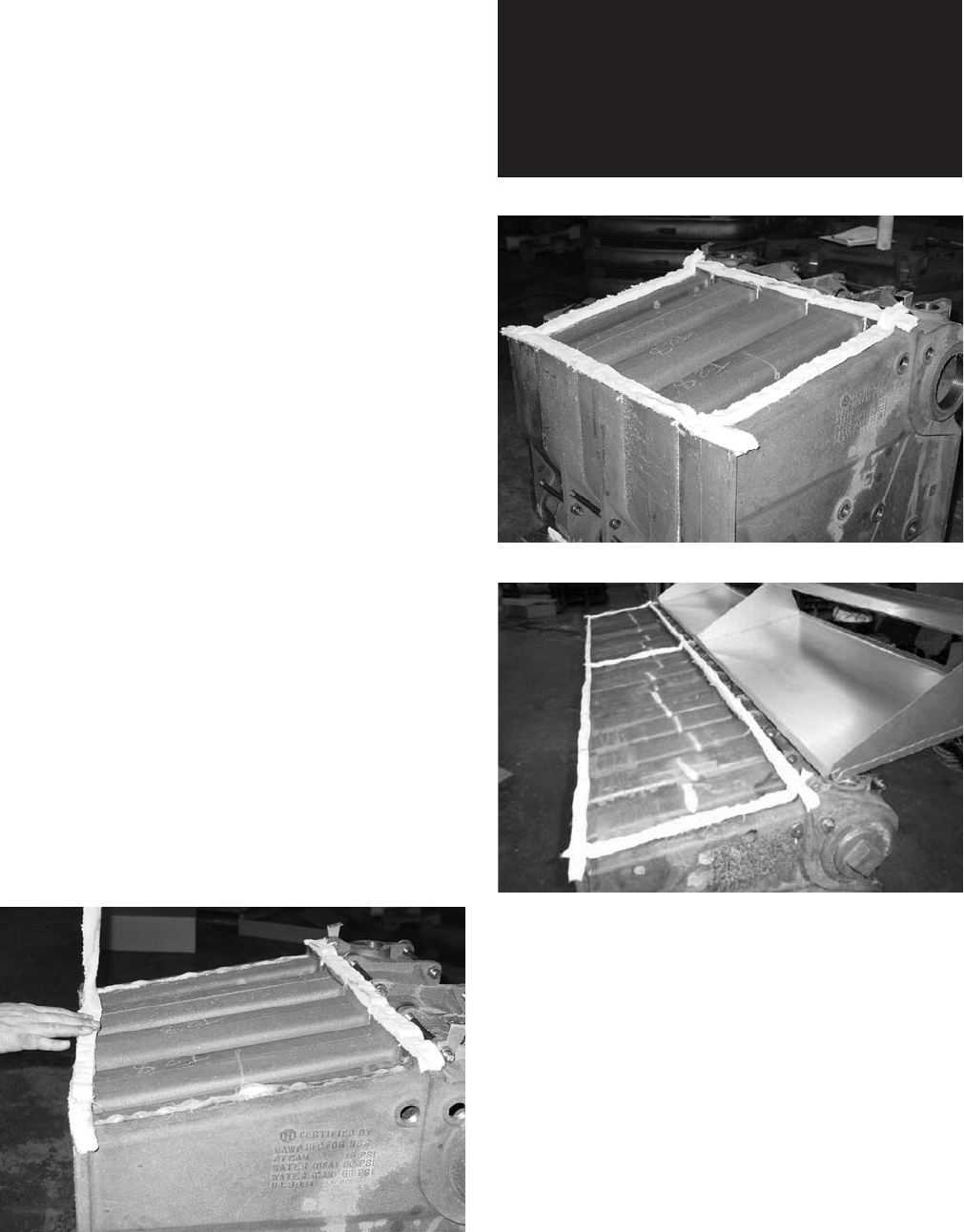

Apply two coats of the spray adhesive to the top of the

casings where the flue collectors will rest. When the

second coat of adhesive is tacky place strips of ceramic

blanket on the castings, Figures 46 and 47A & B.

Figure 46

Flue Collector Ceramic Blanket Placement

WARNING: The ceramic blanket must be

overlapped as shown in Figure 47A & B to

prevent the escape of flue gases. Failure to

properly seal the flue collector to the boiler

sections can result in excessive levels of carbon

monoxide which can result in severe personal

injury or death!

Figure 47A

Ceramic Blanket Placement 5-12 Sect.

Figure 47B

Ceramic Blanket Placement 13-21 Sect.