XL-2000

2

XL-20 0.65 91,000 78 68 8 x8x15 6 x 15 83.56 8

11

/

16

4

9

/

16

6¶ 1

1

/

4

25

3

/

8

XL-30H 0.85 119,000 104 90 8 x8x15 6 x 15 86.00 12

3

/

16

6

5

/

16

61

1

/

4

28

7

/

8

XL-30 1.00 140,000 121 105 8 x8x15 6 x 15 85.04 12

3

/

16

6

5

/

16

6 1

1

/

4

28

7

/

8

1.15 161,000 138 120 8 x8x15 6 x 15 84.12 12

3

/

16

6

5

/

16

61

1

/

4

28

7

/

8

XL-40H 1.25 175,000 152 132 8 x8x15 7 x 15 86.00 15

11

/

16

8

1

/

16

71

1

/

4

32

3

/

8

XL-40 1.35 189,000 162 141 8 x8x15 7 x 15 85.05 15

11

/

16

8

1

/

16

7 1

1

/

4

32

3

/

8

1.55 217,000 186 162 8 x8x15 7 x 15 84.38 15

11

/

16

8

1

/

16

71

1

/

4

32

3

/

8

XL-50 1.80 252,000 217 189 8 x8x15 8 x 15 85.00 19

3

/

16

9

13

/

16

81

1

/

2

35

7

/

8

2.00 280,000 239 206 8 x8x15 8 x 15 84.19 19

3

/

16

9

13

/

16

81

1

/

2

35

7

/

8

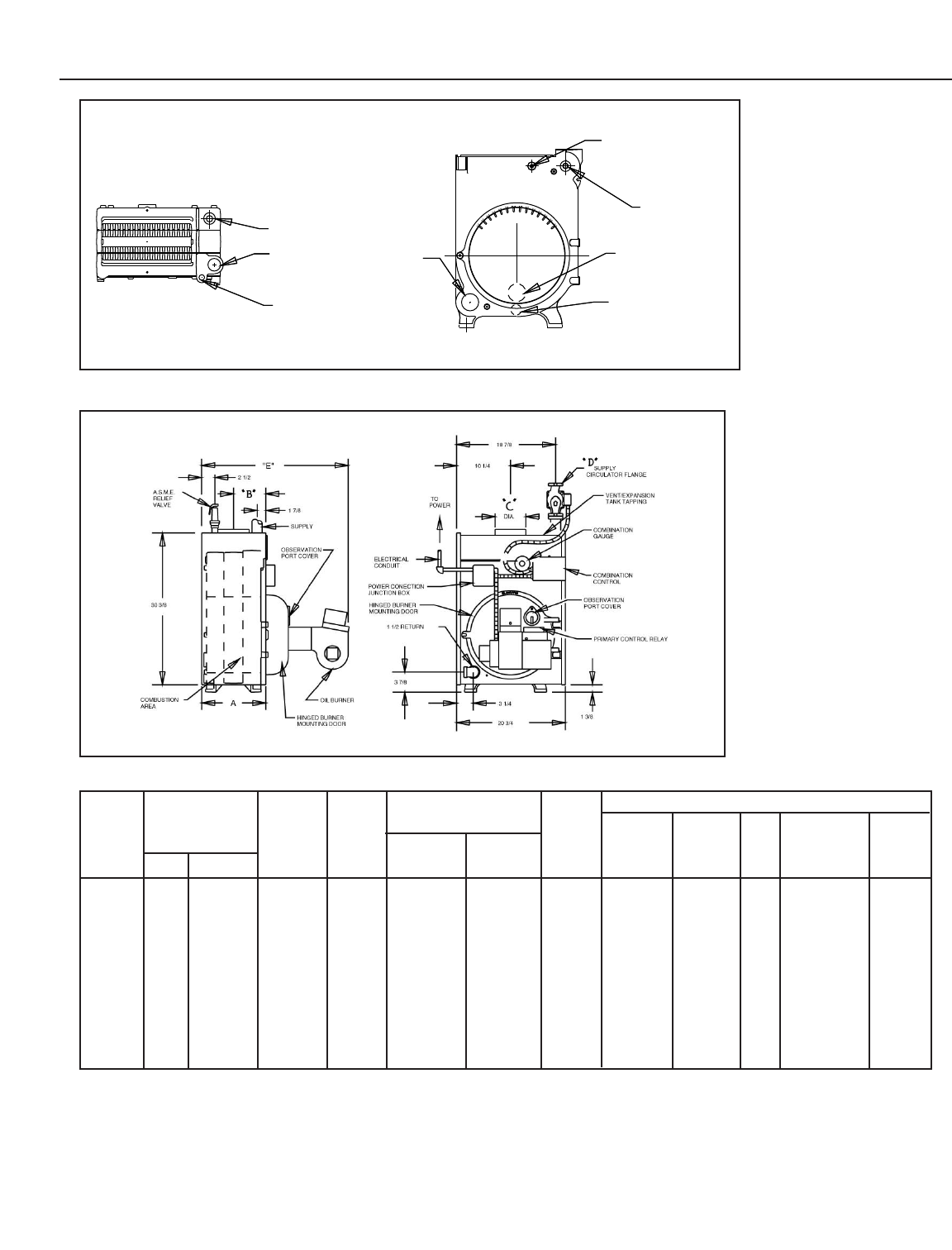

BOILER

MODEL

NO.

GPH BTUH

I=B=R

BURNER

CAPACITY

OIL INPUT † §

D

.O.E.

HEATING

CAPACITY

MBH *

W

ATER

I=B=R

WATER

NET

RATING

MBH *

NOM.

RECT

X HEIGHT‡

(in x in x ft)

I=B=R

CHIMNEY SIZE

DIMENSIONS (inches) #

I.D

. ROUND

X HEIGHT

(in x ft)

AFUE %

BOILER

LENGTH

“A”

FRONT TO

FLUE

“B”

FLUE

DIA.

“C”

CIRCULA

TOR

SUPPLY

FLANGE

“D”

NPT

APPROX.

OVERALL

LENGTH

“E”

Standard working pressure 30 psi.

All boilers hydrostatically tested — A.S.M.E.

* For forced hot water heating systems where the boiler and all piping are

located within the area to be heated, the boiler may be selected on the basis

of D.O.E.capacity output.The net I=B=R output ratings shown are based on

an allowance for piping and pickup of 1.15 (water) or 1.33 (steam). D.O.E.

capacity output is divided b

y the allowance to obtain net rating.The Slant/Fin

Technical Service department should be consulted before selecting a boiler

for unusual piping and pickup requirements such as intermittent system oper-

ation, extensive piping, etc.

† Ratings apply to the use of light oil at 140,000 Btu per gallon and apply only

when burner models listed on pages 11 and 12 of this manual are used, and

are properly adjusted to produce 13% CO

2

.

‡

Nominal clay tile liner dimensions.

§ Water boiler models XL-30 and larger have two firing rates.The boiler is fac-

tory shipped at the lower firing rate.To obtain the higher firing rate, refer to

the XL-2000 boiler installation instructions for the appropriate field adjust-

ments

.“H” models have only one firing rate.

¶

Oblong flue collar.Fits 6” dia.vent connectors.

#

All dimensions subject to nor

mal manufacturing tolerance.

NOTE: All boilers under 300,000 Btuh (87.9 kw) input are tested and rated for

capacity under the U.S.Department of Energy (D.O.E.) Test Procedures for

Boilers.

TABLE 1: Ratings and Dimensions

3

/4" RELIEF

VALVE TAPPING

1

1/2 SUPPLY

T

APPING

1

/2" AIR VENT

O

R EXPANSION TANK

T

APPING

T

OP VIEW

1/4 NPT PRESSURE

& TEMPERATURE TAPPING

F

RONT VIEW

3/4 REAR DRAIN

1 1/2 ALTERNATE

REAR RETURN

1 1/2 RETURN

TAPPING

1/2 NPT

CONTROL TAPPING

Figure 1.

Figure 2.