VICTORY 1

5

burners as described on page 13.

*

To clean burners run a clean flue brush up the tube

until all foreign matter is removed.

IV. SAFETY CHECK FOR CONTROL SYSTEM

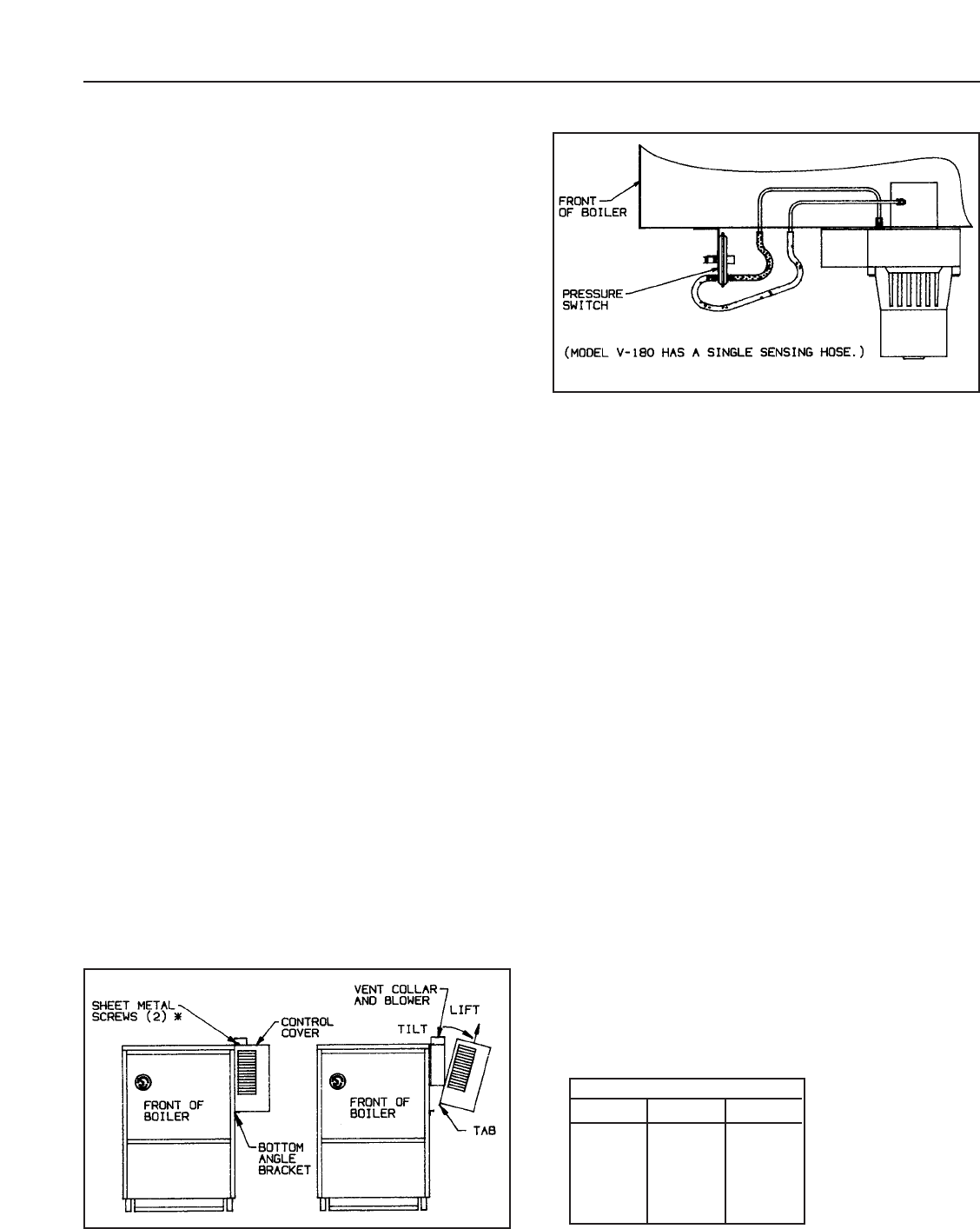

1. Remove Control Cover

To remove control cover, remove the two sheet metal

screws in the top of the top cover. (See figure 13.) Tilt

complete control cover away from boiler and lift up until it

clears the bottom angle bracket. To replace the cover,

reverse procedure. Be sure that the tab on the bottom of

the cover body enters the slot in the bottom angle bracket.

C

AUTION: The boiler should not be operated with cover

off except during certain control checkouts.

2. High Limit Control Test

Set thermostat high enough for boiler water temperature

to reach high limit control setting. When this temperature

is reached, the high limit switch should open and the

main gas valve should close automatically. If the high

limit does not operate to close the main gas valve, the

valve, the high limit or the wiring is faulty. Repair or

replace immediately.

3. Gas Valve Safety Shutdown Test

For boilers equipped with Honeywell S8600 intermittent

pilot systems, with main burners firing, disconnect the

ignition cable from the S8600 IGNITOR BOX. The gas

valve should shut off the main burners.

If the gas valve fails to shut off the main burners when

the test is performed, replace the gas valve.

4. Air Flow Pressure Switch Check

With the main burners firing, remove hose from pressure

switch, the one toward front of boiler, see figure 14.

(Model V-180 has a single sensing hose.) Gas valve

should shut off the main burners.

If the main burners do not shut down, shut off the power

to the boiler and check for continuity across the pressure

switch contacts. If the switch is made when the inducer

is not running, replace the pressure switch with one with

the exact model number as the existing switch.

If the switch is open and burners do not shut off, replace

the ignition control or gas valve.

5.

Check for gas leaks from valve and gas piping to burners

and pilot. If leaks are f

ound, repair or replace as

required.

V. 1. Providing Protection from Freezing

Anti-freeze is sometimes used in hydronic heating sys-

tems to protect against freeze-up in the event of power

failure or control shutdown when the building is unoc-

cupied. It should be recognized that unless the build-

ing is kept above freezing temperature by some

means, the plumbing system is not protected.

Two types of anti-freeze may be used: ETHYLENE

GLYCOL, used in automobiles, has desirable proper-

ties, but is toxic. Its use may be prohibited when sys-

tem water/glycol solution is in contact with a potable

water vessel (as with a tankless heater). PROPYLENE

GLYCOL is used in the quick-freeze food industry; it is

practically non-toxic. Its use may be permitted when

tankless heaters are used. When anti-freeze must be

used, inhibited propylene glycol is recommended.

Useful information on the characteristics, mixing pro-

portions, etc. of glycol in heating systems is given in

Technical Topics No. 2A, available from the Hydronics

Institute, 34 Russo Place, Berkeley Heights, NJ 07922.

Consult glycol manufacturers for sources of propylene

glycol.

2. Water Treatment

A good water treatment program will not only extend

the useful life of this boiler but it will also save much of

the time and expense of repairs made necessary by

preventable occurrences.

A reputable water treatment company should be con-

sulted to evaluate and determine the best overall treat-

ment program for your boiler equipment.

VI.

KEEP

THE BOILER AREA CLEAR AND FREE FROM

COMBUSTIBLE MA

TERIALS

, GASOLINE, AND O

THER

FLAMMABLE

V

APORS AND LIQ

UIDS

.

Figure 13.

Figure 14. Top View of Boiler

BOILER

W

A

TER CONTENT

Model Pounds Gallons

V-33 17.50 2.1

V-60 24.75 3.0

V

-90

32.00

3.8

V-120 39.25 4.7

V-150 46.50 5.6

* For service remove ONLY these two screws. DO NOT remove any

other screws.