VICTORY 1

3

8. Turn on all electric power to the appliance.

9. Set thermostat to desired setting.

10. If the appliance will not operate, follow the instructions

"To Turn Off Gas To Appliance" and call your service

technician or gas supplier.

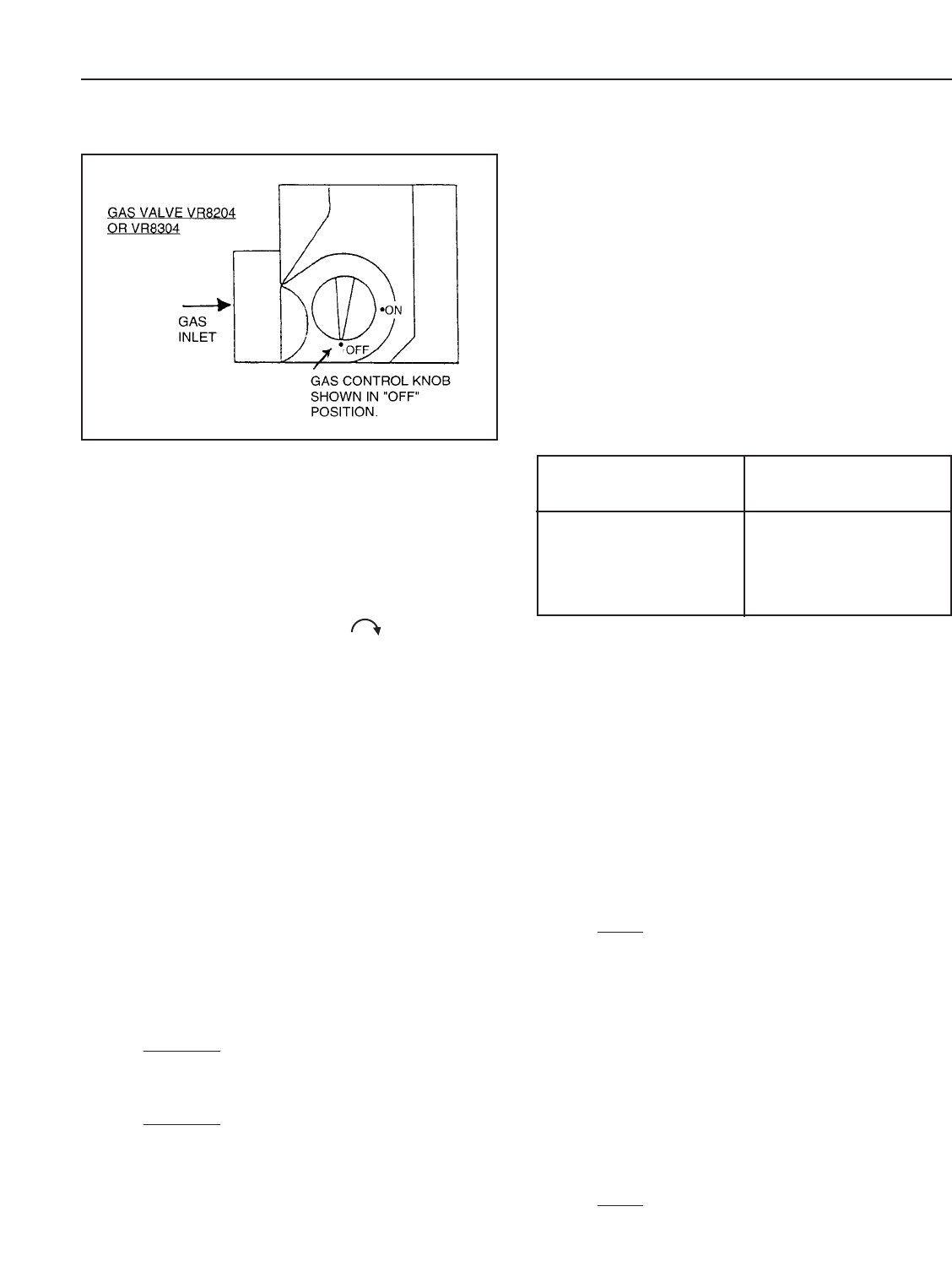

To Turn Off Gas to Appliance

1. Set thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Turn gas control knob clockwise to “OFF”.

DO NOT force.

III. BURNER ADJUSTMENT

A. Adjust gas input rate:

1. Consult gas supplier for higher heating value of gas

(Btu/cu.ft.).

2. Set thermostat high enough so that boiler will

remain on while checking rate.

3. Measure manifold pressure at 1/8" tapping. Correct

manifold pressure for gas used is printed on boiler

r

ating plate

.

NOTE: Gas pressure may be adjusted

by turning pressure regulator screw on combination

gas valve (turn clockwise to increase pressure,

counterclockwise to decrease pressure).

a.

Input for PR

OPANE is appro

ximately at r

ating

sho

wn on rating plate when manifold pressure is

9-1/2" water column.

b. Input for NATURAL GAS is approximately at rat-

ing when manifold pressure is 3-1/2" water col-

umn, but should be chec

ked on the gas meter:

Btuh Input = Btu/cu. ft. x cu. ft. metered in 3 min-

utes x 20

Example 1:

F

or 1000 Btu/cu.ft.

gas, this becomes:

Btuh Input = cu. ft. metered in 3 minutes

x 1,000 Btu/cu.ft. x 20

Example 2:

For 1050 Btu/cu.ft.

gas

, this becomes:

Btuh Input = cu. ft. metered in 3 minutes

x 1050 Btu/cu.ft. x 20

4. The higher* heating value of gas varies substantially for

different localities. Consult with Slant/Fin’s Technical Ser-

vice Dept. for re-orificing procedures if any of the following

a

pply:

a. Boiler (burner) is overfiring. CAUTION! National

Fuel Gas Code (ANSI Z223.1-latest edition) does

NOT permit firing at a higher input rate than the

i

nput rate indicated on the boiler rating plate in

order to avoid hazardous conditions such as explo-

s

ion or carbon monoxide poisoning.

b. Poor higher* heating value of gas is causing the

actual input to be substantially lower than the

rating plate indication.

* “Higher heating” value of gas is commonly

known as “heating value”.

The gas metered in 3 minutes to obtain rated input for

each boiler model, using 1000 Btu/cu.ft. gas, is tabulat-

ed in gas rate table.

B. Main Burners

1. Fire the boiler continuously for at least 15 minutes,

to reach burner operating temperature.

2. Observe the flames, all burners. The base of all

flame jets should be blue. The tips should be blue

shading to orange. NOTE: Dust, disturbed by any

movement, will cause bright orange flames. Wait

for dust to settle.

3. For one burner, close the air shutter until some of

its flame jet tips turn yellow-white, indicating insuffi-

cient primary air. Then open shutter until whitish

tips disappear completely. Set all burner shutters to

the same opening. Observe to make sure that no

yellow-white tips appear over any portion of the

flame. Small yellow tips at the pilot location are

permitted.

NO

TE: This adjustment method gives MINIMUM

primary air setting for safe combustion. DO NOT

attempt to make this adjustment unless burners are

at operating temperature. Adjustment should be

made with burner access panel in final operating

position. Use of a mirror may be helpful to observe

flames. Note that burner ports are on top of main

burner tube.

C. Main Burner Ignition Checkout and Pilot Adjustment.

1. The pilot flame must not smother or snuff out when

tested as follows:

a. Main burner ignition from cold start-repeat.

b. Continued operation of main burner.

c.

Main b

ur

ner ignition with appliance at maximum

operating temperature after prolonged operation.

NO

TE: Observe operation of the pilot burner with

appliance doors in the final oper

ating position.

Use

of a mirror ma

y be helpful.

Boiler rated input in

cu. ft./hr. of 1000 Btu/cu. ft.

Natural Gas

33

60

90

120

150

180

Cubic Feet Gas Consumption

1000 Btu/cu. ft. gas, in

3 minutes, at rated input

1.65

3.00

4.50

6.00

7.50

9.00

Figure 12. IID System with Honeywell VR8204 or VR8304

Gas Valve