VICTORY 1

1

at test pressures equal to or less than 1/2 PSIG.

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap must be pro-

vided, as illustrated on page 2.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for

the type of gas used. Gas supply pressure should never

be less than minimum or more than maximum pressure

when the boiler or any other appliance is turned on or off.

ELECTRICAL CONTROLS AND WIRING

A. The electrical power to the boiler must be on a separately

fused and live circuit.

B. If an external electrical source is utilized, the boiler, when

installed, must be electrically grounded in accordance

with the requirements of the authority having jurisdiction

or, in the absence of such requirements, with the National

Electrical Code, ANSI/NFPA No. 70-latest edition.

C. Basic control wiring diagrams are given on page 17 and

18. Other control systems may be factory supplied: see

User's Information Manual and instructions packed with

control system supplied.

D. After placing the boiler in operation, the safety shutoff

device must be tested. See page 14 safety check.

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required to obtain combustion and

v

entilation. ALL AIR COMES FROM OUTSIDE, directly

through wall openings to the boiler or through unsealed

openings around windows, doors, etc. in the whole building.

When buildings are insulated, caulked and weather-stripped,

now or later on, direct openings to outside may be required

and should be provided. If the boiler is not near an outside

wall, air may be ducted to it from outside wall openings.

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and Venti-

lation, of the National Fuel Gas Code, ANSI Z223.1-latest

edition, or applicable provisions of the local building codes.

The following recommendation applies to buildings of ener-

gy-saving construction, fully caulked and weather stripped:

Provide one GRILLED opening near the floor and one near

the ceiling on an outside wall near the boiler (or duct from

such openings to the boiler), EACH opening to be a mini-

mum of one square inch per 2000 Btuh input to ALL APPLI-

ANCES in the area. For a total appliance input of 200,000

Btuh, each opening will be 100 square inches

.

A g

r

illed

opening 10"X10" has 100 square inches of area. If fly

screen must be used over openings, double the area and

inspect and clean the screen frequently.

Openings must never be reduced or closed. If doors or win-

dows are used for air supply, they must be locked open.

Protect against closure of openings by snow and debris.

Inspect frequently.

No mechanical draft exhaust or supply fans are to be used in

or near the boiler area.

The flow of combustion and ventilating air to the boiler must

not be obstructed.

WATER PIPING

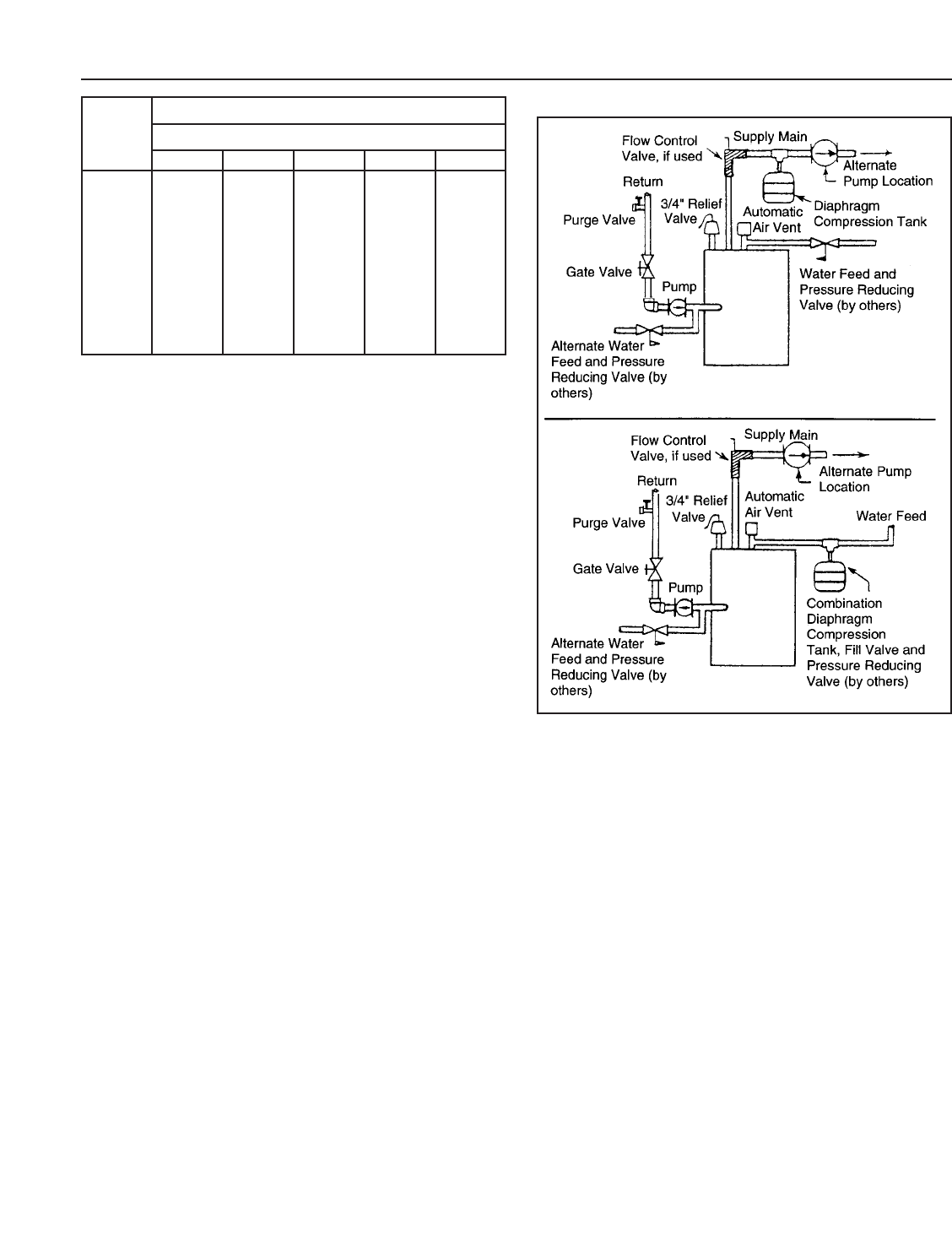

I. CIRCULATING SYSTEMS

A. Packaged water boilers are equipped with a water circu-

lating pump, mounted to return the water into the boiler.

For some installations, the pump should be on the sup-

ply main. See PUMP LOCATION, on page 12.

II. AIR CONTROL SYSTEM

A. DIAPHRAGM-TYPE COMPRESSION TANKS are used

to control system pressure in an AIR ELIMINATING

SYSTEM; an automatic air vent is used to REMOVE air

from the system water. See illustration.

If system pressure needs fur

ther control, add an addi

-

tional tank or install a larger capacity tank.

Locate the tank near the boiler, as illustrated.

An automatic air v

ent should be installed in the top of

the

boiler

.

See illustr

ation.

1

/2 3/4 1 1-1/4 1-1/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

5

0 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

9

0 40 84 160 320 490

100 38 79 150 305 460

Length

of Pipe

in Feet

Gas Flow In Piping -- cu. ft. per hr.

Iron Pipe Size (Ips)—inches

Figure 10. Air Eliminating System

At pressure drop of 0.3 in.water, specific gravity = 0.60.