MARK V – MOUNTED OVERARM PIN ROUTER 555970

31

moving your workpiece into the bit un-

til the edge of your stock also makes

contact with the Guide Pin.

Once contact is made with the Guide

Pin, move the workpiece around and

away from the Starter Pin, maintaining

contact with the Guide Pin at all times

until you’ve completed your cut.

Re-position the Depth Control Handle

for each subsequent pass until your de-

sired final depth-of-cut is reached. Once

you’ve completed the final pass, loosen

the Depth Control Handle, raise the

Router, re-tighten the Handle and turn

off the Motor. Only when the Motor has

stopped completely should you remove

and inspect the workpiece.

USING PILOTED BITS FOR

DECORATIVE EDGING

Cutting decorative edges on workpieces with

piloted bits is a common operation for a

hand-held router. With this operation, the Bit

pilot controls your lateral depth-of-cut, while

the vertical depth-of-cut is controlled by the

plunge mechanism of your hand-held router

(in the case of plunge-style routers), or by

changing the height relationship between the

router motor and its base through some

other method.

With the Overarm Router, the process is al-

most identical...with two differences:

• First and foremost, with the Overarm

Router, your hands are used to grip the

workpiece instead of the router motor.

This provides improved visibility of the

cut and allows you to rout the edges of

workpieces that may be too small or

oddly-shaped to grip properly with

clamping devices.

WARNING

NEVER attempt to work with a small

piece of stock less than 12" x 12" or that

puts your hands closer than 3" from

the guard.

• And secondly, with the Overarm Router,

your stock is supported by the Worktable,

while your vertical depth-of-cut is con-

trolled with micro-precision by the up-

down action of the Arm.

Piloted router Bits come in two styles: 1) Bits

with solid steel pilots...or...2) Bits with a

ball bearing pilot.

When making cuts with a piloted Bit, your

up-down depth-of-cut — and the number

of cuts you’ll have to make to form the

complete profile — can vary, based on two

factors:

• The amount of stock that must be re-

moved to produce the profile you want.

If you’re forming an edge on thick stock,

you may not be able to cut a full profile

all at once without workpiece burning or

tear-out. In these cases, you’ll have to

make more than one pass...lowering the

Arm with each subsequent pass until the

profile you desire is achieved.

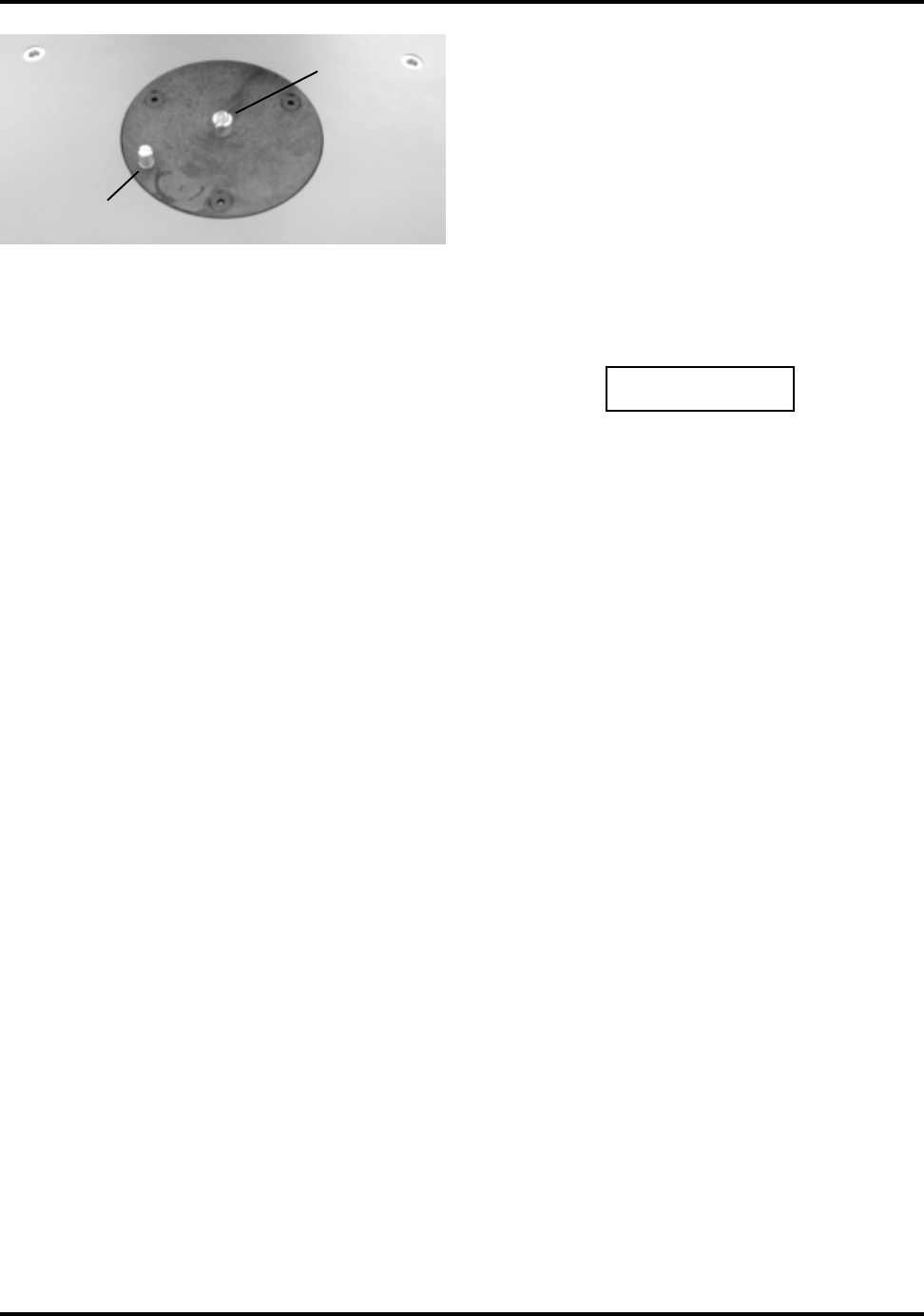

Figure 23. Use the Pin Routing Table Insert

when routing against a pin.

STARTER

PIN

GUIDE

PIN