MARK V – MOUNTED OVERARM PIN ROUTER 555970

23

2. Cut out your fixture blank – As men-

tioned, fixtures should be made of a

laminate-covered material, such as 3/4"

thick sink cut-outs. Be sure to make

your fixture blank about 4" longer and

4" wider than your finished project, so

you have room to grip your fixture and

still keep your hands well out of harm’s

way.

3. Mount your template to the fixture

blank – Mount it to the non-laminate-

covered side of your fixture blank. Cen-

ter the template in the fixture and use

screws or nails to hold the template

firmly in position. Be sure to put screws

or nails through each segment of the

template and don’t forget to counter-

sink all screw or nail heads to keep

them from marring your Router Table

surface.

If there are to be multiple grooves in

your fixture (such as those in Figure 10),

be sure to leave adequate space between

the template segments for your Guide

Pin to ride in while you make your

fixture.

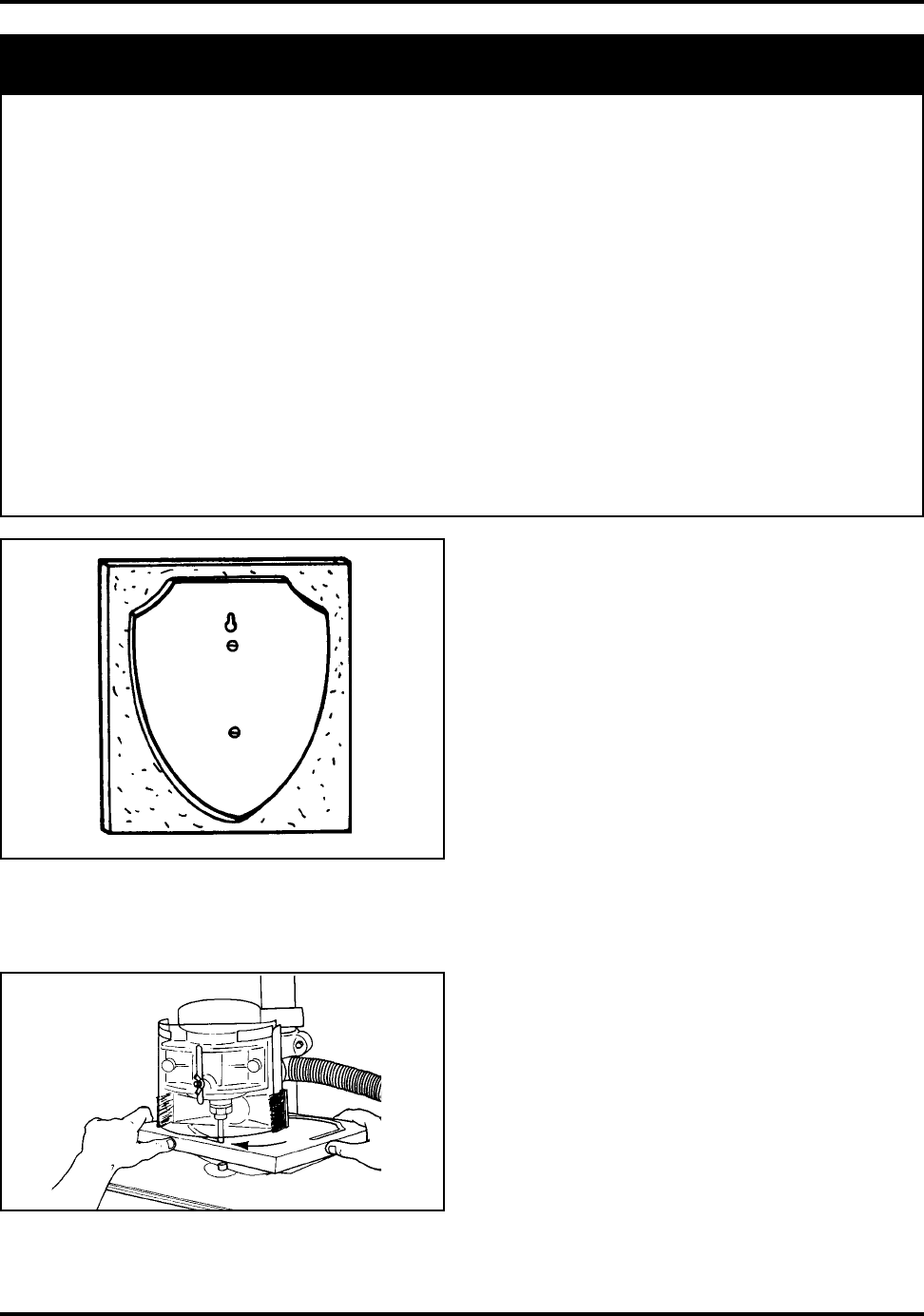

Figure 13. Using an existing item

(in this case a plaque) as a template

for making your fixture

Figure 14. Guide the edge of your existing

item against the pin to cut a matching

groove in the laminate side of your fixture.

WHY MAKE A GROOVED FIXTURE?

The question is often asked...

”Why should I cut grooves in a fixture instead of just screwing a template to one side of

the fixture, the workpiece to the other, and guiding my template against the Table Pin,

as I would when making the fixture?”

The answer is simple. When guiding your fixture

against a Table Pin, you must con-

stantly maintain a steady pressure against the Pin at all times. A momentary lapse in

concentration can easily result in a cut going outside your desired shape. As a result,

against-the-pin routing is always a slower, more risky process than dropping the fixture

over the Table Pin.

When routing over a Table Pin, the Pin is captive in its groove and cannot go outside

your desired shape unless the fixture is raised off the table surface, r eleasing the Pin from

its groove. Over-the-Pin routing allows you to move more rapidly through the cut, with

little fear of slip-ups that could ruin your workpieces.