555970 MARK V – MOUNTED OVERARM PIN ROUTER

14

CAUTION

Over-tightening the Motor Bracket nuts

may cause damage to the motor and/or

housing of your router.

INSTALL THE REAR GUARD AND

DUST COLLECTOR ASSEMBLY

Install a flat washer over each stud of the

front Motor Clamp, and then slip the rear

guard/dust chute with strip brushes onto

the clamp studs and secure with two more

flat washers and wing nuts. See Figure 5 for

correct assembly order.

MOUNT THE OVERARM ROUTER

TABLE ONTO THE MARK V

WORKTABLE

Model 500

Remove the MARK V Table Insert. Use the

two buttonhead Allen capscrews with wash-

ers to mount the Overarm Router Table to

the MARK V Worktable by inserting them

through the two elongated mounting holes

in the Router Table and threading them di-

rectly into the Model 500 MARK V Table In-

sert mounting holes (See Fig. 6).

Models 505, 510, 520

Use the sliding T-nuts and 1/4"-20 flat head

machine screws provided. Lay the Router

Table right-side-up on a flat surface in front

of you with the eight threaded insert holes

away from you. You will notice two pairs of

countersunk holes in the Table surface, about

7-1/2" in from the “front” edge of the Table

(See Fig. 6). These are the holes you will use

to mount your Overarm Router’s Table to

your Model 505, 510 or 520 MARK V’s Work-

table.

For the majority of your conventional and

pin routing operations, you will use the two

left holes in each pair to mount the Table to

the “front” Miter Gauge slot in your MARK

V’s Worktable. This approach will provide

the maximum workpiece support in “front”

of your Router bit and motor.. . and allow

you to use your Two-Piece Router Fence (in-

cluded).

If you would prefer to have more workpiece

support “behind” your Router bit and mo-

tor, use the two right holes in each pair to

mount the Table to the “back” Miter Gauge

slot in your MARK V’s Worktable. When us-

ing this approach, the Table must be rotated

180° and installed with the eight threaded

Fence inserts toward the “front” of the Table.

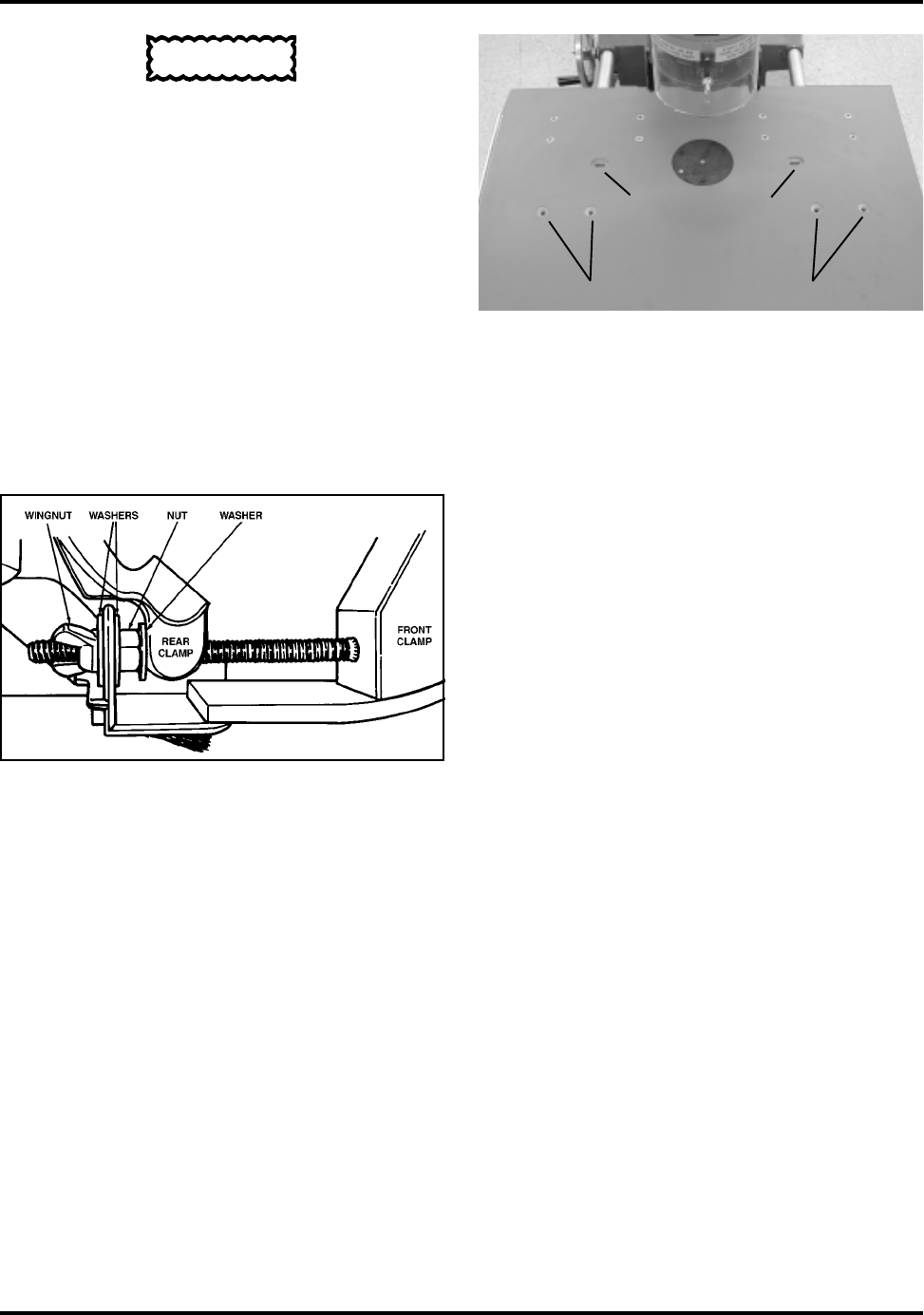

Figure 6. Use the left hole of each pair

when mounting the Worktable on

Model 505, 510 and 520 MARK V’s for

most applications. Use counterbored

slots for Model 500.

Figure 5. Overhead view of proper motor

clamp hardware assembly order

(looking down from above).

FOR MODELS 505, 510,520

FOR MODEL 500