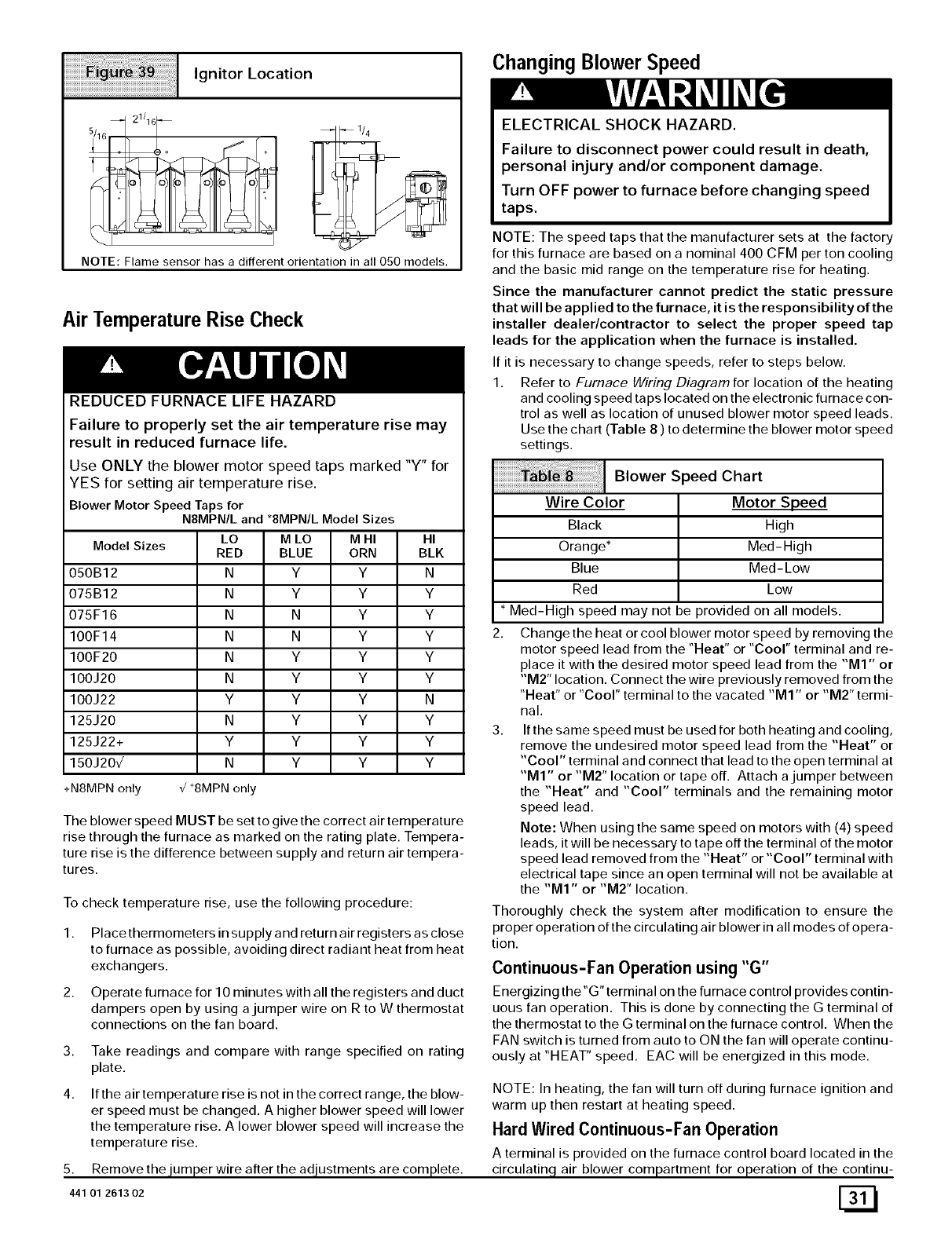

Ignitor Location

NOTE: Flame sensor has a different orientation in all 050 models.

Air TemperatureRise Check

REDUCED FURNACE LIFE HAZARD

Failure to properly set the air temperature rise may

result in reduced furnace life.

Use ONLY the blower motor speed taps marked "Y" for

YES for setting air temperature rise.

Blower Motor Speed Taps for

NSMPNtL and *8MPN/L Model Sizes

ModelSizes

050B12

075B12

075F16

100F14

100F20

100J20

100J22

125J20

125J22+

150J20{

+N8MPN only

LO

RED

N

N

N

N

N

N

Y

N

Y

N

{ _8MPNonly

M LO M HI HI

BLUE ORN BLK

Y Y N

Y Y Y

N Y Y

N Y Y

Y Y Y

Y Y Y

Y Y N

Y Y Y

Y Y Y

Y Y Y

The blower speed MUST be set to give the correct air temperature

rise through the furnace as marked on the rating plate. Tempera-

ture rise is the difference between supply and return air tempera-

tures.

To check temperature rise, use the following procedure:

1. Place thermometers in supply and return air registers as close

to furnace as possible, avoiding direct radiant heat from heat

exchangers.

2. Operate furnace for 10 minutes with all the registers and duct

dampers open by using a jumper wire on R to W thermostat

connections on the fan board.

3,

4.

Take readings and compare with range specified on rating

plate.

If the air temperature rise is not in the correct range, the blow-

er speed must be changed. A higher blower speed will lower

the temperature rise. A lower blower speed will increase the

temperature rise.

5. Removethe ULU.m._erwire after the adiustments are complete.

441 01 261302

Changing Blower Speed

ELECTRICAL SHOCK HAZARD.

Failure to disconnect power could result in death,

personal injury and/or component damage.

Turn OFF power to furnace before changing speed

taps.

NOTE: The speed taps that the manufacturer sets at the factory

for this furnace are based on a nominal 400 CFM per ton cooling

and the basic mid range on the temperature rise for heating.

Since the manufacturer cannot predict the static pressure

that will be applied to the furnace, it is the responsibility of the

installer dealer/contractor to select the proper speed tap

leads for the application when the furnace is installed.

If it is necessary to change speeds, refer to steps below.

1. Refer to Furnace Wiring Diagram for location of the heating

and cooling speed taps located on the electronic furnace con-

trol as well as location of unused blower motor speed leads.

Use the chart (Table 8 ) to determine the blower motor speed

settings.

I Blower Speed Chart

Wire Color Motor Speed

Black High

Orange* Med- High

Blue Med-Low

Red Low

* Med-High speed may not be provided on all models.

2. Change the heat or cool blower motor speed by removing the

motor speed lead from the "Heat" or "Cool" terminal and re-

place it with the desired motor speed lead from the "M1" or

"M2" location. Connect the wire previously removed from the

"Heat" or "Cool" terminal to the vacated "M1" or "M2" termi-

nal.

3. If the same speed must be used for both heating and cooling,

remove the undesired motor speed lead from the "Heat" or

"Cool" terminal and connect that lead to the open terminal at

"MI" or "M2" location or tape off. Attach a jumper between

the "Heat" and "Cool" terminals and the remaining motor

speed lead.

Note: When using the same speed on motors with (4) speed

leads, it will be necessary to tape off the terminal of the motor

speed lead removed from the "Heat" or "Cool" terminal with

electrical tape since an open terminal will not be available at

the "M1" or "M2" location.

Thoroughly check the system after modification to ensure the

proper operation of the circulating air blower in all modes of opera-

tion.

Continuous-Fan Operationusing "G"

Energizing the"G" terminal on the furnace control provides contin-

uous fan operation. This is done by connecting the G terminal of

the thermostat to the G terminal on the furnace control. When the

FAN switch is turned from auto to ON the fan will operate continu-

ously at "HEAT" speed. EAC will be energized in this mode.

NOTE: In heating, the fan will turn off during furnace ignition and

warm up then restart at heating speed.

Hard Wired Continuous-Fan Operation

A terminal is provided on the furnace control board located in the

circulatinq, air blower compartment for operation of the continu-