9

2A. Water Supply & Chemical Mixing– Manual Fill:

• Pour up to 12 gallons of hot water into the solution tank at the front of the machine. The water

temperature cannot exceed 180°F.

• Measure and add the appropriate amount of the desired liquid chemical to the water in the solution tank.

The amount of chemical will vary depending on the type of chemical used, the amount of water in the

tank, and the material being cleaned; consult the chemical packaging for specific mixture ratios.

• Powdered chemicals should be dissolved in water before adding to the water in the solution tank.

DO NOT RUN OUT OF WATER WHILE USING THE MACHINE! Ensure that the tank

contains enough water to complete each job. If the water level is low: stop cleaning, turn off the

pump, and refill the tank. Running the pump dry will damage the pump and void the warranty.

2B. Water Supply & Chemical Dilution – Auto-Fill:

• The chemical dilution rate is controlled by the metering tip, and the dilution rate can only be changed by

changing the metering tip (See “How to Change the Metering Tip” on Page 10 for instructions.)

Chemical Feed Setup:

• Remove the chemical feed hose from the solution tank.

• Place the end of the hose into a container of liquid chemical.

• If the tip is removed, and the proportioning system operated with no tip, the dilution rate will be 8:1 (the

equivalent to adding 16-1/4oz of chemical to each gallon of water.)

• The standard tip included with the M1200 is the turquoise tip with a dilution rate of 256:1. This means

that for each gallon of water flowing into the machine, 1/2 ounce of chemical will be added.

• If a fresh water rinse with no chemical is desired, simply leave the chemical feed hose inside the

solution tank.

Pro

p

ortionin

g

Valve

Chemical Feed Hose

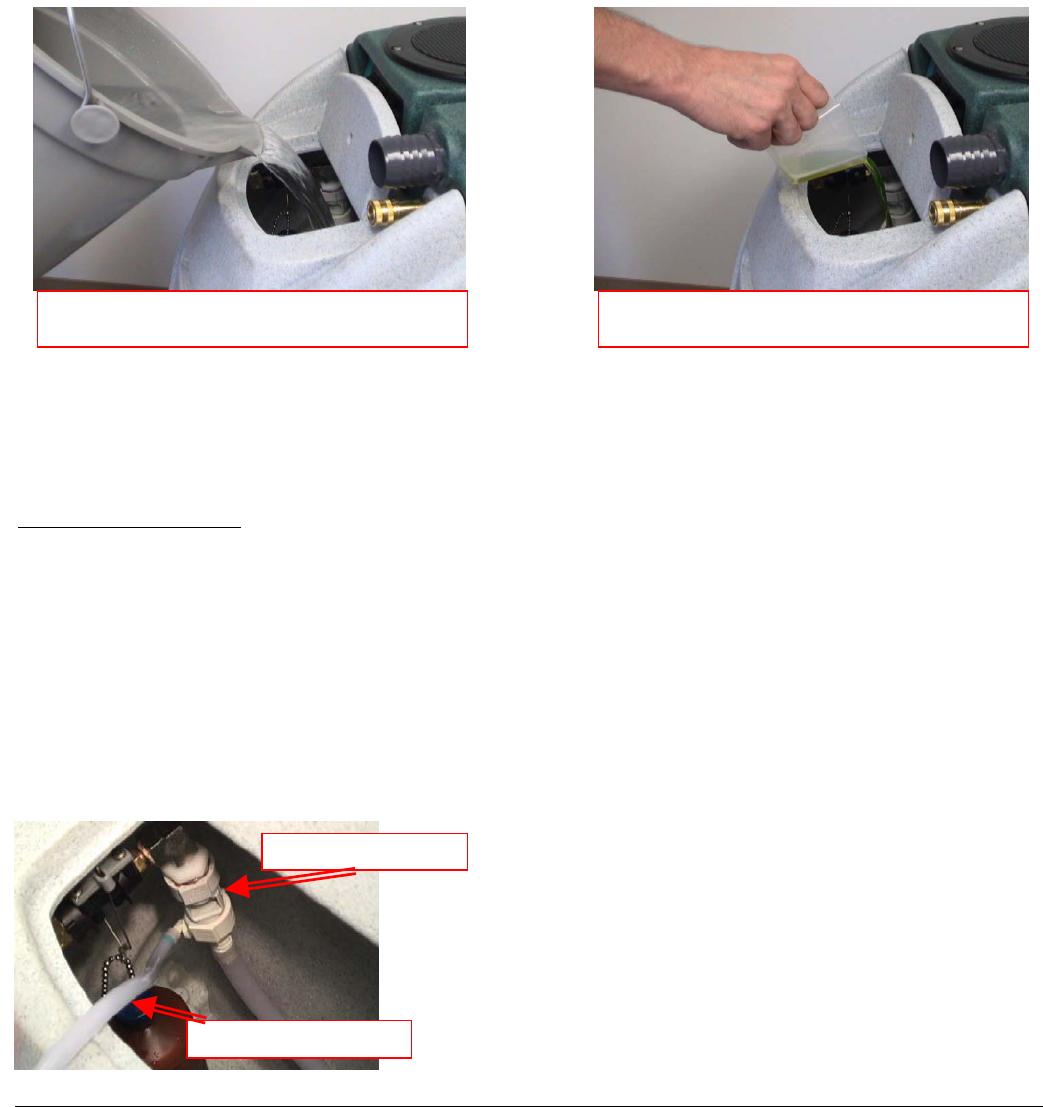

Add appropriate amount of chemical to water

in solution tank

Pour appropriate amount of hot water into

solution tank