CHECKING AND ADJUSTING

PROCEDURE 1—GAS VALVE SAFETY SHUTDOWN TEST

With main burners firing, disconnect ignition cable from intermittent pilot control box. Gas valve should shut off main burners. TURN OFF

ELECTRIC POWER to boiler before reconnecting ignition cable to prevent electric shock.

PROCEDURE 2—PILOT BURNER ADJUSTMENT

Pilot flame should surround 3/8- to 1/2-in. of pilot sensor. (See Fig. 9.) If flame needs adjusting, proceed as follows:

1. Remove screw cover over pilot adjusting screw. (See Fig. 10.)

2. Insert small screwdriver and adjust flame as needed. (See Fig. 9 and 11.) Turn screw counterclockwise to increase flame and clockwise to

decrease flame.

3. Replace screw cover over pilot adjusting screw.

PROCEDURE 3—MAIN BURNER(S)

The main burners do not require primary air adjustment and are not equipped with primary air shutters. Main burner flames should form sharp

blue inner cones in a softer blue out mantel, with no yellow. Puffs of air from blowing on the flame or stamping on the floor will cause the flames

to turn orange momentarily. This is not unusual. Remain still when observing the main burner flames. If the flame appearance is not correct, check

main burner orifices and the burner throat and flame ports for dust and lint obstruction. It may be necessary to remove the rollout shield to observe

the main burner flames. Replace rollout shield after observation. (See Fig. 11.)

PROCEDURE 4—LIMIT CONTROLS ADJUSTMENT

Instructions for each control are included with controls.

Table 6 shows recommended boiler water temperatures. These settings can be changed after becoming familiar with system operation. For

example, if system is not giving quite enough heat in very cold weather, the limit setting can be raised to 220°F.

PROCEDURE 5—THERMOSTAT HEAT ANTICIPATOR ADJUSTMENT

Instructions for final adjustment of thermostat are packaged with thermostat.

Set heat anticipator at 0.2.

Check thermostat operation. When set above temperature indicated on thermometer, boiler burners should ignite. Make certain thermostat shuts

boiler off when room temperature reaches selected setting and starts boiler operating when room temperature falls a few degrees.

PROCEDURE 6—SAFETY CONTROLS CHECK

After setting limit control to desired setting, check to see if it shuts off gas supply to burners. Set thermostat to call for heat and let boiler run until

temperature of water reaches limit setting. Gas valve should shut off and circulator should keep running until thermostat is satisfied or water cools

enough to restart burners through limit control.

To check operation of contacts in pressure switch, disconnect rubber tubing (located between blower and pressure switch) from pressure switch

while boiler is operating. The burners should extinguish, and blower should keep running. When tubing is reconnected to pressure switch, ignition

sequence should begin, resulting in ignition of main burners.

Finally, set thermostat for desired temperature. Special conditions in home and location of thermostat govern this setting.

Safe lighting and other performance criteria were met with gas manifold and control assembly provided on boiler when boiler underwent tests

specified in ANSI Z21.13.

Fig. 9—Pilot Flame and Sensor

A95160

3

⁄8″ to

1

⁄2″

FLAME

ON SENSOR

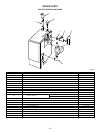

Fig. 10—Automatic Gas Valve

A95520

GAS CONTROL

KNOB SHOWN

IN "ON" POSITION

PILOT

ADJUSTMENT

(UNDER CAP

SCREW)

GAS

INLET

INLET

PRESSURE

TAP

WIRING

TERMINALS (3)

OUTLET

PRESSURE

TAP

GROUND

TERMINALS (2)

GAS

OUTLET

PILOT

OUTLET

OFF

ON

PRESSURE REGULATOR

ADJUSTMENT

(UNDER CAP SCREW)

Table 6—Recommended Boiler Water Temperatures

TYPE OF HEATING UNIT LIMIT CONTROL SETTING

Standing Radiators 180°F

Baseboard and Convector Radiators 200°F

—16—

→