MAYCO LS400/LS500 PUMP — OPERATION AND PARTS MANUAL — REV. #6 (09/19/11) — PAGE 59

LS400/LS500 PUMP — TRAILER SAFETY GUIDELINES

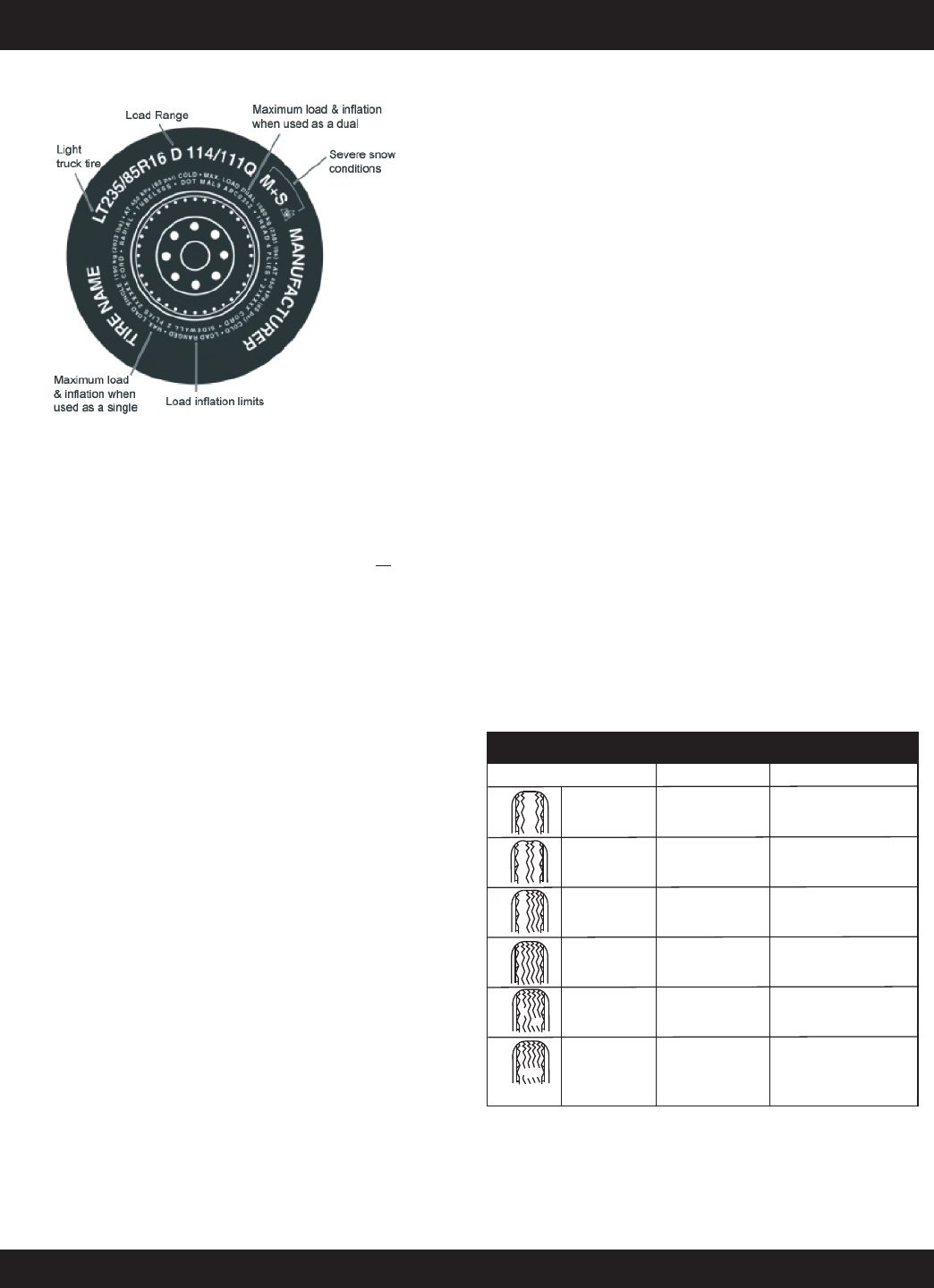

Figure 58. UTQGS Tire Information

Reference Figure 58 for additional tire information for light

trucks.

Tires for light trucks have other markings besides those

found on the sidewalls of passenger tires.

LT: The “LT” indicates the tire is for light trucks or trailers.

ST: An “ST” is an indication the tire is for trailer use only.

Max. Load Dual kg (lbs) at kPa (psi) Cold: This informa-

tion indicates the maximum load and tire pressure when the

tire is used as a dual, that is, when four tires are put on each

rear axle (a total of six or more tires on the vehicle).

Max. Load Single kg (lbs) at kPa (psi) Cold

This information indicates the maximum load and tire

pressure when the tire is used as a single.

Load Range

This information identifies the tire’s load-carrying capabili-

ties and its inflation limits.

Tire Safety Tips

Slow down if you have to go over a pothole or other

object in the road.

DO NOT run over curbs or other foreign objects in the

roadway, and try not to strike the curb when parking.

Check tire inflation pressure weekly during use to in-

sure the maximum tire life and tread wear.

DO NOT bleed air from tires when they are hot.

Inspect tires for uneven wear patterns on the tread,

cracks, foreign objects, or other signs of wear or trauma.

Remove bits of glass and foreign objects wedged in the

tread.

Make sure your tire valves have valve caps.

ALWAYS check tire pressure on tow vehicle and trailer

before towing. Check tire pressure at least once a month.

DO NOT overload tow vehicle. Check the tire

information and loading placard for safe allowable tire

loading conditions.

Tire Repair

The proper repair of a punctured tire requires a plug for the

hole and a patch for the area inside the tire that surrounds

the puncture hole. Punctures through the tread can be

repaired if they are not too large, but punctures to the sidewall

should not be repaired

. Tires must be removed from the

rim to be properly inspected before being plugged and patched.

Replacing Worn or Damaged Tires

Replace the tire before towing the trailer if the tire treads

have less than 1/16 inch depth or the telltale bands are

visible. Check inflation pressure weekly during use to insure

the maximum tire life and tread wear. A bubble, cut or bulge

in a side wall can result in a tire blowout. Inspect both side

walls of each tire for any bubble, cut or bulge; and replace a

damaged tire before towing the trailer.

Table 8 below will help pinpoint the causes and solutions of

tire wear problems.

WEAR PATTERN SOLUTION

CAUSE

Center Wear

Over Inflation

Adjust pressure to

particular load per

tire manufacturer.

Edge Wear Under Inflation

Make sure load does

not exceed axle rating.

Align wheels.

Side Wear

Adjust pressure to

particular load per

tire manufacturer.

Loss of chamber

or overloading.

Toe Wear

Incorrect toe-in

Align wheels.

Cupping

Out-of balance

Check bearing adjust-

ment and balance tires.

Flat Spots

Wheel lockup &

tire skidding.

Avoid sudden stops

when possible and

adjust brakes.

TABLE 7 TIRE WEAR TROUBLESHOOTING