MAYCO LS400/LS500 PUMP — OPERATION AND PARTS MANUAL — REV. #6 (09/19/11) — PAGE 43

LS400/LS500 PUMP — MAINTENANCE (PUMP)

WHEEL BEARINGS

After every 6 months of operation inspect the wheel bearings.

Once a year, or when required, disassemble the wheel hubs

remove the old grease and repack the bearings forcing grease

between rollers, cone and cage with a good grade of high

speed wheel bearing greases (never use grease heavier than

265 A.S.T.M. penetration “No. 2.”).

1. Fill the wheel hub with grease to the inside diameter of

the outer races and also fill the hub grease cap.

2. Reassemble the hub and mount the wheel. Then tighten

the adjusting nut, at the same time turn the wheel in

both directions, until there is a slight bind to be sure all

the bearing surfaces are in contact.

3. Back off the adjusting nut 1/6

to 1/4 turn or to the nearest

locking hole or sufficiently to allow the wheel to rotate

freely within limits of .001” to .010” end play. Lock the

nut at this position.

4. Install the cotter pin and dust cap, and tighten all

hardware.

EXTENDED STORAGE INSTRUCTIONS

The following preventative maintenance is recommended

for extended periods of storage.

1. Check brake system for proper fluid level in master

cylinder and bleed all lines.

2. Lubricate all links and pivots to prevent any rusting.

3. Remove wheel and drum assemblies and spray a good

anti-corrosion compound (CRC formula 5-56) under rubber

boot on forward end of brake wheel cylinder. Avoid

spraying drum and brake lining.

4. Grease all bearings and reinstall wheel and drum

assemblies.

5. Make sure breakaway cable is fully released.

6. After extended storage, refer to the Maintenance Steps

listed above to insure that the trailer is ready for towing.

PRESSURE TEST

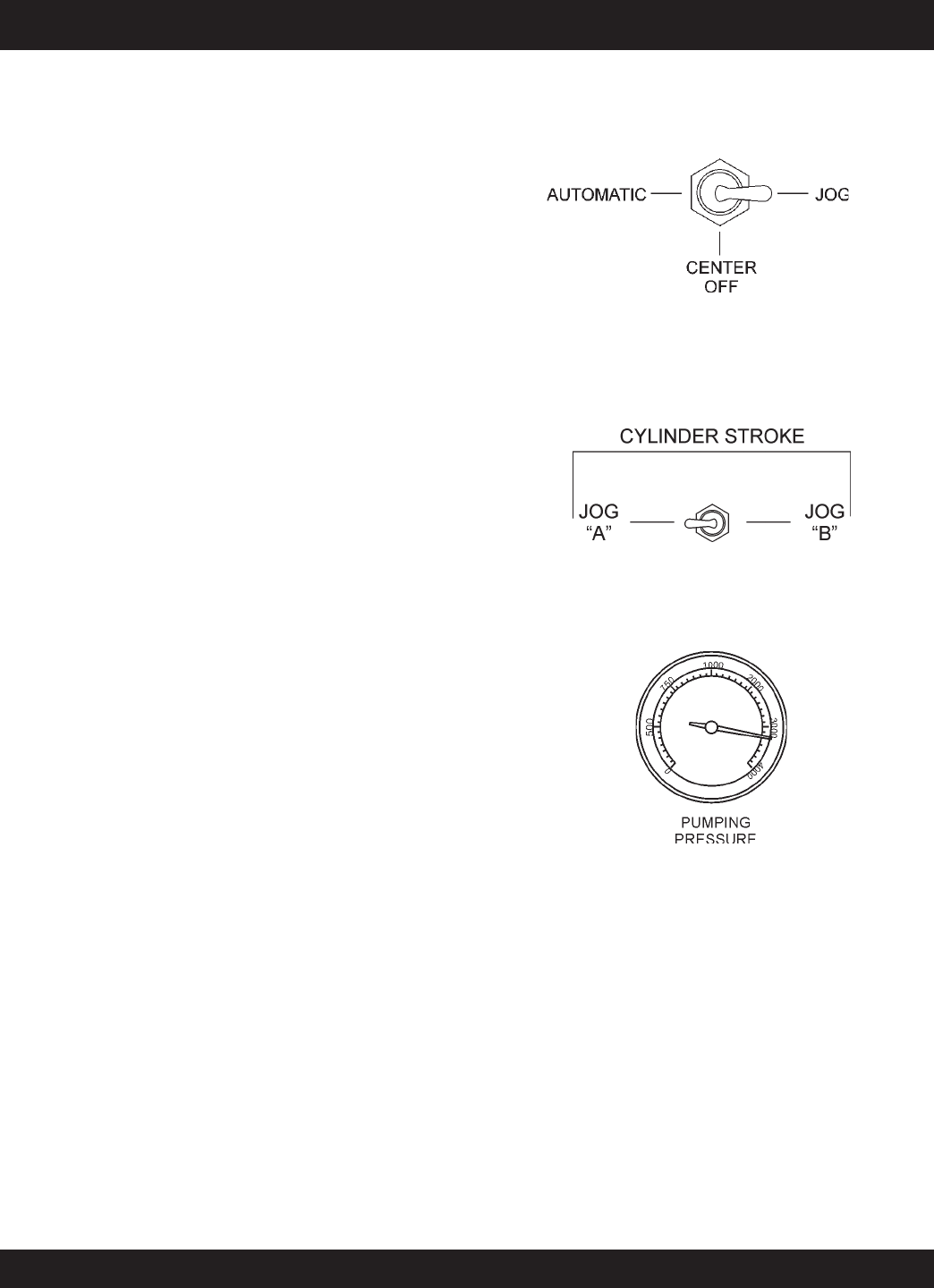

1. To determine the pressure of the Hydraulic System, set

the

Cylinder Stroke Control Switch

(Figure 42) to the

JOG position.

Figure 43. Manual Cylinder Jogging Switch

13. The Pumping Pressure Gauge (Figure 44) should read

approximately 4400 ± 50 PSI.

Figure 44. Pumping Pressure Gauge

2. Turn and hold the Manual Cylinder Jogging Switch

(Figure 43) to either JOG “A” or JOG “B” position to

test the pressure of that cylinder.

Figure 42. Cylinder Stroke Control Switch (JOG)