3. MOUNTING AND WIRING

3

−

12

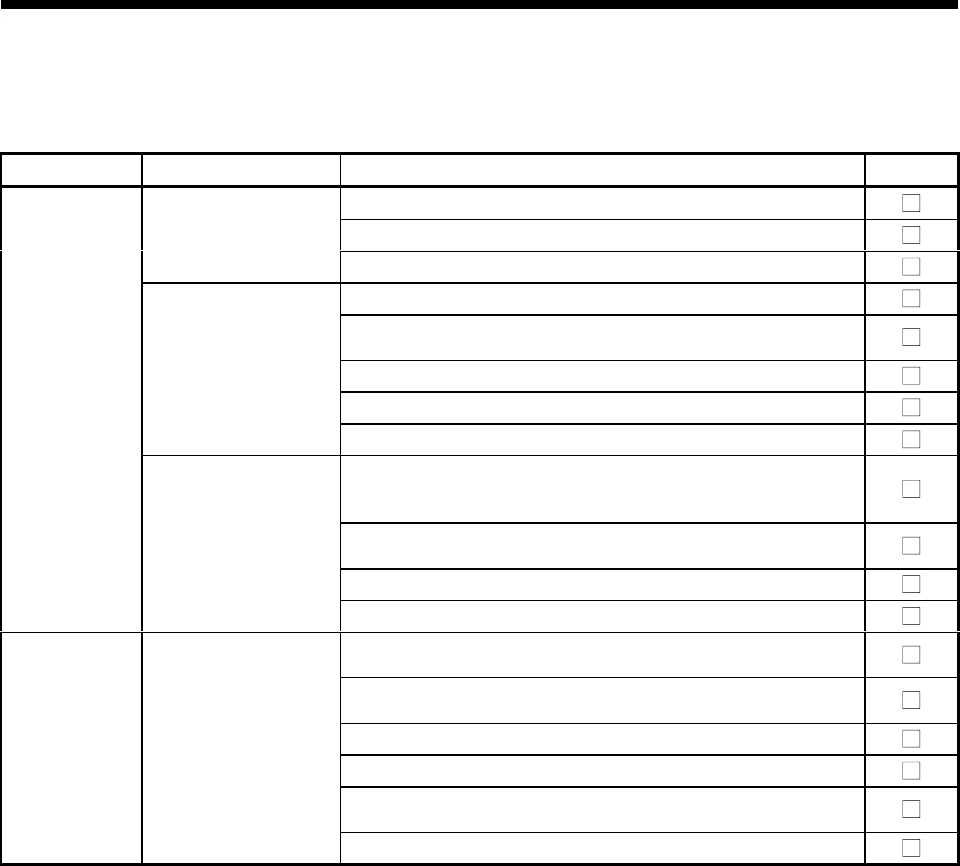

3.6 Mounting/Wiring Checklist

At the worksite, copy the following table for use as a check sheet.

Item Sub Item Mounting/Wiring Confirmation Check

Check for loose or distorted mounting.

Check that the mounting screw tightening torque is as specified.Base unit mounting

Check the unit for damage.

Check that the mounted module models are correct.

Check that the A172SENC and A1SY42 are mounted to the

motion slots.

Check for loose or distorted mounting.

Check that the mounting screw tightening torque is as specified.

Mounting of modules to

base unit

Check the modules for damage.

Check that the amplitude, eccentricity and axial displacement

relative to the machine side rotary shaft are within the

permissible values.

Check that a flexible coupling is used for coupling with the

machine side rotary shaft.

Check the module for damage.

Unit/module

mounting

Synchronous encoder

mounting

Check that excessive impact was not given during mounting.

Check that the 100VAC, 200VAC and 24VDC wires are twisted

as closely as possible and run in the shortest distance.

Check that the 100VAC, 200VAC and 24VDC wires are not

bundled with and run close to the power and I/O wires.

Check that each wiring is of the specified wire size.

Check for loose terminal block screws.

Check that the terminal block screw tightening torque is as

specified.

Wiring

Running of power

supply and I/O wires

Check that LG and FG are class 3-grounded.