7 Domestic water heaters (continued)

47

Installation & Service Manual

Water Chemistry

The required temperature rise and the standard pump sizing

are based on the heating of potable water with chemistry

within the specified limits. Caution should be used when

heating water softened to less than 5 grains per gallon. Many

commercial water softeners reduce hardness to 0 grains which

may result in long term problems in the system. Softened

water will usually have a lower pH which can be aggressive

and corrosive causing non-warrantable damage to the heater,

pump, and associated piping.

Corrosion due to water chemistry generally shows up first in

the hot water system because heated water increases the rate

of corrosive chemical reactions. As water is heated it becomes

less soluble. The dissolved minerals and solids will precipitate

and collect as scale if water velocity is not properly controlled.

Follow the temperature rise requirements for unsoftened

water. Consult the manufacturer when heating potable water

with hardness or total dissolved solids exceeding these

specifications. Heating of high hardness and/or high total

dissolved solids water may require a larger circulating pump,

an optional cupro-nickel heat exchanger and a revised

temperature rise specification based on the water chemistry of

the water to be heated.

Softened Water Systems

Decreasing the flow rate will reduce the erosion process,

however the heat exchanger should be monitored to ensure

the scale/liming process is not made worse. The unit should

be placed on a comprehensive inspection schedule until

optimum flow rates can be established. Problematic water

areas may require heat exchanger inspection every two weeks.

The total scale accumulation should never exceed the

thickness of a piece of paper. Should scale accumulation

exceed this thickness the flow rate will need to be increased.

The tubes should not have a bright shiny copper look. This

would indicate that the erosion process has begun and the

flow rate will need to be decreased. Once the proper flow rates

have been established the inspection intervals can be

increased to every 30 days, once a quarter, or to a bi-annual

inspection. This procedure should ensure proper operation of

the unit as long as the water quality stays consistent.

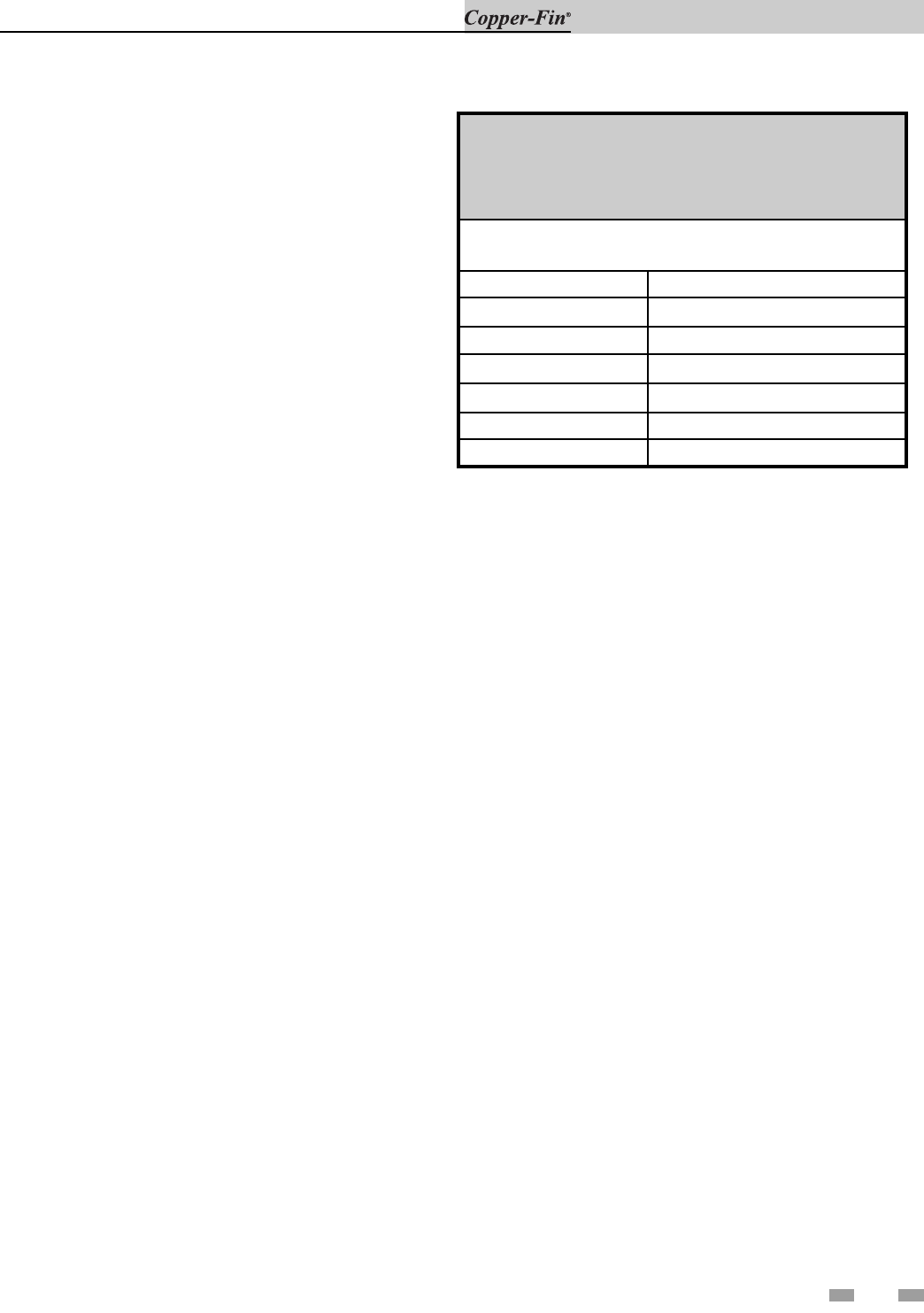

TABLE - 7B

COMMON WATER MANIFOLD SIZE FOR

MULTIPLE HOT WATER SUPPLY BOILER

INSTALLATIONS

Pipe sizing chart provides minimum pipe size for common

manifold piping and tank tappings to ensure adequate flow.

Number of Units Common Manifold Size (Min.)

1 2"

2 2"

3 2 1/2"

4 3"

5 3 1/2"

6 3 1/2"

Pump Operation

1. The water heater/hot water supply boiler must be

connected to a properly sized pump that circulates water

between the heater and storage tank.

2. A standard water heater is furnished with a 1/6 HP, 120

VAC, 3.6 AMP circulating pump to be mounted on the

units in let water connection. This pump is sized based on

installation of a single storage tank and heat er in close

proximity. If the number of fit tings and straight pipe

exceeds the quantities shown in this sec tion, a larger pump

will be required.

3. The pump must run continuously when the burners are

firing.

4. Lubricate the pump to the manufacturers rec om men da tions.

Pump damage due to inadequate lu bri ca tion is

non-warrantable.

5. Pump is sized to heater input and water hard ness. Care

should be taken to size the pump correctly. See “Water

Chemistry”, this page.

The standard pump selection is based on the fol low ing pipe and

fittings from the unit to the stor age tank:

6 - 90° elbows 2 - ball valves

2 - unions 1 - cold water tee

Plus the following length of straight pipe based on the heater

size:

90,000 through 360,000 Btu/hr Models

Not more than 45 feet of straight pipe

399,999 through 500,000 Btu/hr Models

Not more than 25 feet of straight pipe

For every elbow and tee in excess of those shown above,

DEDUCT 5 FEET from maximum allowable straight pipe in

heater to tank circulating loop.