3 Gas connections (continued)

21

Installation & Service Manual

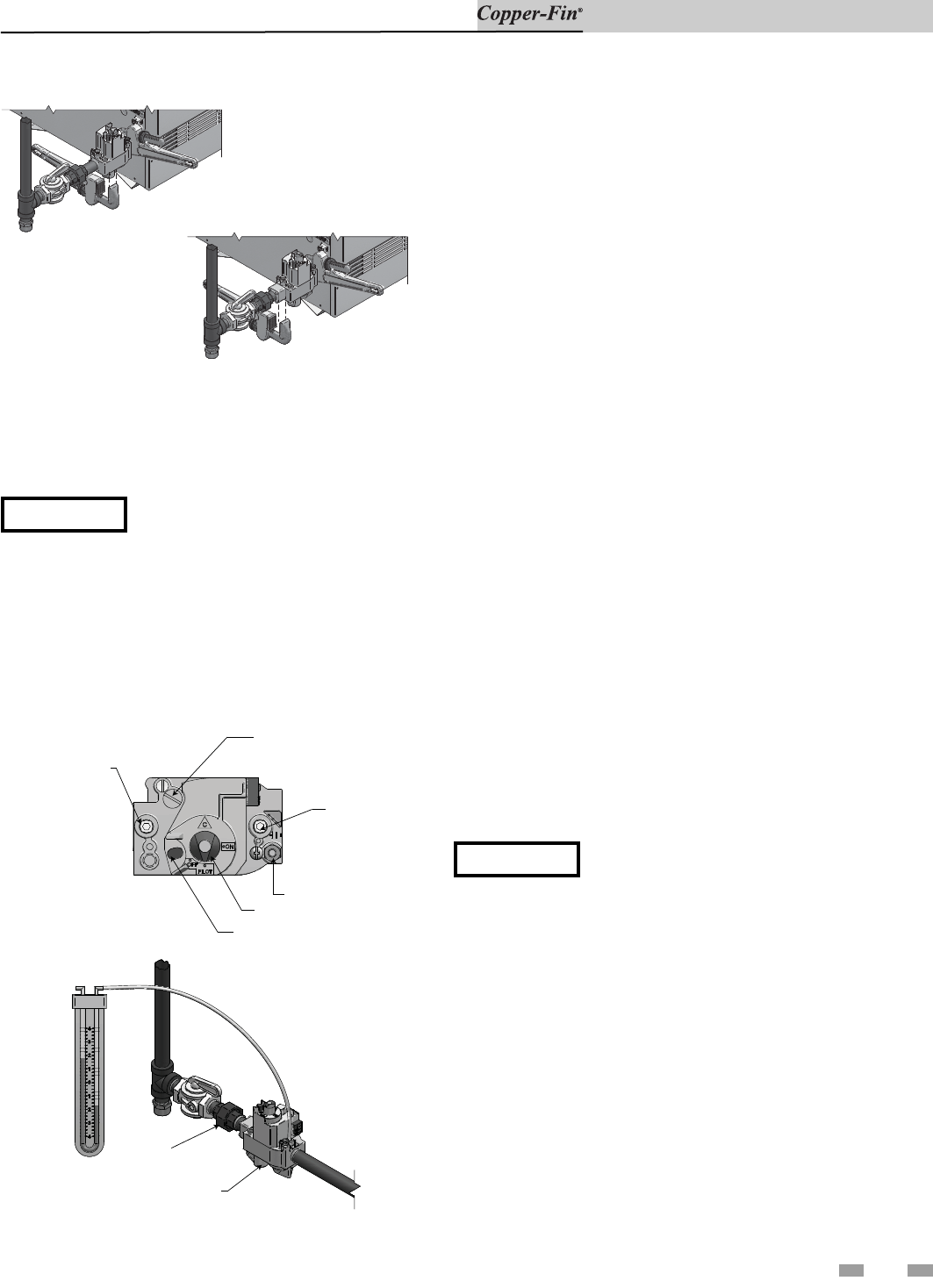

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE

IS USED

APPLY WRENCH FROM

BOTTOM OF GAS CONTROL

TO EITHER SHADED AREA

WHEN FLANGE

IS NOT USED

Figure 3-2_Wrench

8. For L.P. gas, consult your L.P. gas supplier for expert

installation.

IMPORTANT

Upon completion of any piping

con nec tions to the gas system, leak test all

gas con nec tions with a soap solution

while system is un der pressure.

Immediately repair any leaks found in the

gas train or related components. Do Not

op er ate an appliance with a leak in the gas

train, valves or related piping.

Gas Manifold Pressure Adjustment

Procedure

PRESSURE REGULATOR

ADJUSTMENT

(UNDER SCREW CAP)

OUTLET

PRESSURE TAP

PILOT OUTLET

GAS CONTROL KNOB

RED RESET BUTTON

INLET

PRESSURE

TAP

UNION

GAS VALVE

MANOMETER

Figure 3-3_Manifold Pressure Adjustment

1. Turn the power “OFF” at the main dis con nect switch.

2. Turn gas valve control knob to “PILOT” po si tion on

standing pilot models. Ensure that the stand ing pilot

remains on. If the pilot goes out, follow the “Lighting

Instructions” in Section 6 - Startup for standing pi lot

models to light the pilot. Turn gas valve control knob to

“OFF” po si tion on spark ignition models.

3. Remove the 1/8" hex plug located on the out let side of the

gas valve and install a fitting suitable to connect to a

manometer or magnahelic gauge. See FIG. 3-3. Minimum

range of scale should be up to 5" w.c. for Natural gas

mod els and 10" w.c. for L.P. gas models.

4. The 500,000 Btu/hr model will have two gas valves with a

pressure regulator on each valve. Repeat the following

adjustment pro ce dure to set the manifold pressure on each

gas valve.

5. Remove the pressure regulator adjustment cap screw on

the gas valve. See FIG. 3-3 for location.

6. Turn the power “ON” at the main dis con nect switch.

7. Turn gas valve control knob to “ON” po si tion.

8. Set the thermostat(s) to call for heat.

9. Observe gas regulator pressure when all burn ers are firing.

See Table 3B, Manifold Pressure (page 19) for proper

regulator pressure settings.

10. If adjustment is necessary, turn regulator ad just ment screw

clockwise to raise regulator gas pres sure, counterclockwise

to lower gas pres sure, to proper setting. N

OTE: Adjustment

fitting is plas tic and may require slightly greater turning

force than a metal fitting.

11. Turn the power “OFF” at the main dis con nect switch.

NOTICE

Do not increase regulator pres sure beyond

specified pressure setting.

12. Turn gas valve control knob to “PILOT” po si tion on

standing pilot models. Turn gas valve control knob to

“OFF” position on spark ignition models.

13. Remove fitting from the gas valve and re place the 1/8" hex

plug that was previously removed and tighten.

14. Repeat the adjustment procedure for the sec ond gas valve

on the 500,000 Btu/hr model.

15. Turn the gas valve control knob(s) to “ON” position.

16. Turn the power “ON” at the main dis con nect switch. The

appliance is now ready to op er ate.

If manifold pressure can not be properly adjusted, use the

procedure on page 22 to check gas supply pressure with a

manometer connected to the inlet pressure tap on the gas

control.