26

4 Hydronic piping

Installation & Service Manual

9. Inspect the liquid level in the expansion tank. The

system must be full and under normal operating

pressure to ensure proper water level in the expansion

tank. Ensure that diaphragm type ex pan sion tanks are

properly charged and not water logged.

10. Start the boiler according to the Section 6 - “Start-Up

Instructions” in this manual. Operate the system,

including the pump, boiler and radiation units, for one

hour.

11. Recheck the water level in the expansion tank. If it

exceeds half the tank volume, open the tank to reduce

the water level. Recheck pres sure charge on diaphragm

type tanks.

12. Shut down the entire system and vent all ra di a tion units

and high points in the system.

13. Close the water makeup valve and check the strainer and

pressure reducing valve for sediment or debris. Reopen

the water makeup valve.

14. Verify system pressure with the boiler pres sure gauge

before beginning regular operation.

15. Within three days of start-up, recheck and bleed all air

vents and the expansion tank using these instructions.

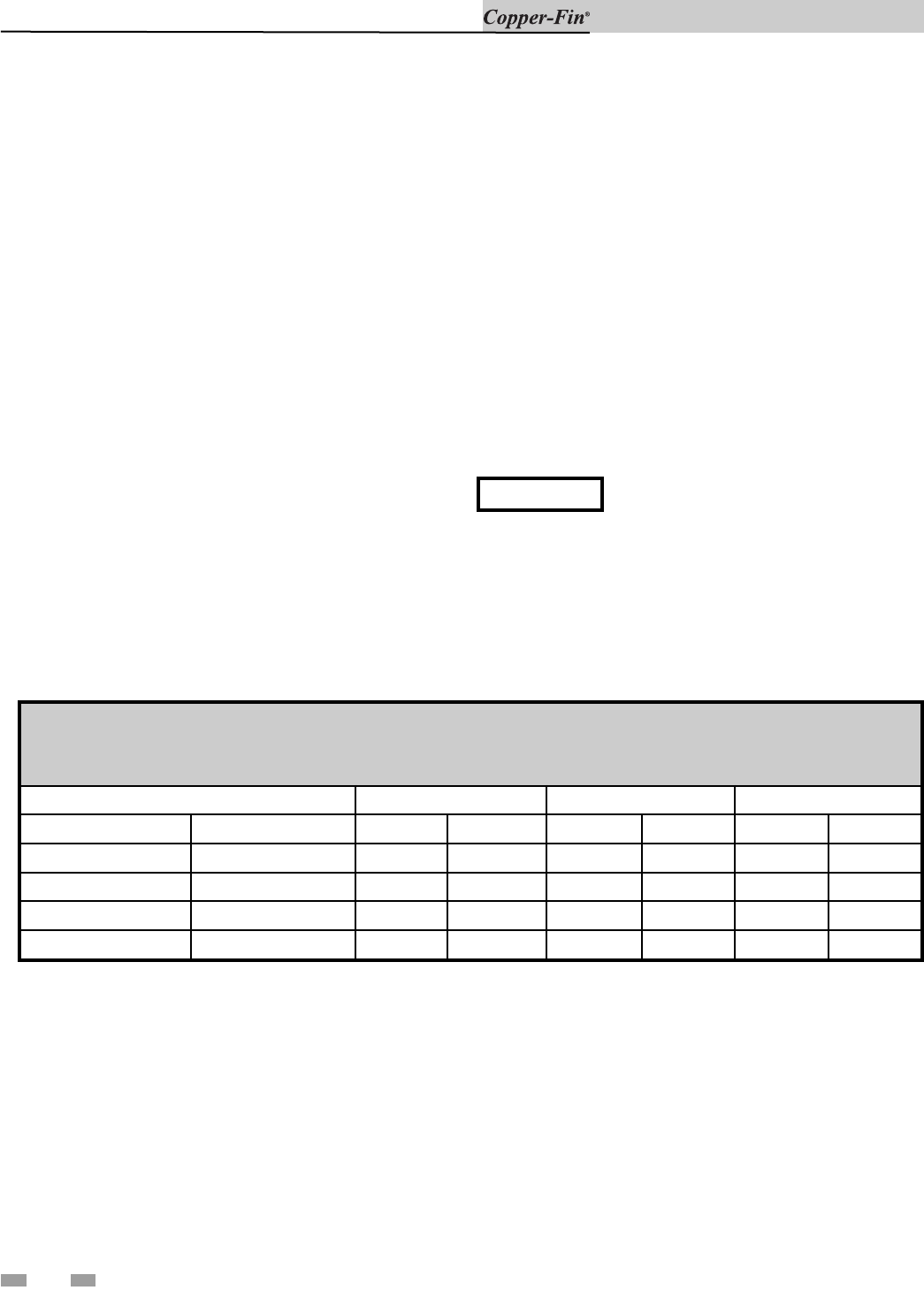

TABLE - 4B

SYSTEM TEMPERATURE RISE CHART

Based on Boiler Output in Btu/hr

Btu/hr

20°F T 30°F T 40°F T

Input Output GPM Ft/hd GPM Ft/hd GPM Ft/hd

315,000 258,300 26.0 4.1 17.3 2.2 13.0 1.3

360,000 295,200 29.7 5.4 19.8 2.5 14.9 1.5

399,999 327,180 -- -- 22.0 3.6 16.5 2.0

500,000 410,000 -- -- 27.6 6.6 20.7 3.5

Piping of the Boiler System

The drawings in this section (see FIG’s 4-4 through 4-6) show

typical heating boil er piping installations. Before beginning the

in stal la tion, consult local codes for specific plumb ing

re quire ments. The installation should provide unions and

valves at the inlet and outlet of the boil er so it can be isolated for

service. The boiler cir cu lat ing pump, air sep a ra tor, expansion

tank and oth er components required for proper installation

must be purchased locally. An air separation device must be

supplied in the in stal la tion piping to eliminate trapped air in

the system. Lo cate a system air vent at the highest point in the

sys tem. The system must also have a properly sized expansion

tank installed. Typically, an air charged di a phragm-type

expansion tank is used. The expansion tank must be installed

close to the boiler and on the suction side of the system pump

to ensure proper op er a tion.

ƽ CAUTION

This boiler system should not be operated at

less than 12 PSIG.