Site Preparation and Installation

10

2.4.2 Evaporator Air Distribution

Filter Box

The optional filter box mounts directly to the return air opening of the evaporator. The filter box is

supplied with two (2) 20% (Liebert part no. A-0320) or 30% (Liebert part no. A-0400) 25" x 20" x 4" fil-

ters.

Connections for Ducted Systems

Use flexible duct work or non-flammable cloth collars to attach duct work to the unit and to help con-

trol the transmission of vibrations to building structures. Insulation of duct work is vital to prevent

condensation during the cooling cycle. The use of a vapor barrier is required to prevent absorption of

moisture from the surrounding air into the insulation.

If the return air duct is short, or if noise is likely to be a problem, sound-absorbing insulation should

be used on the duct. Duct work should be fabricated and installed in accordance with local and

national codes.

NOTE

Do not operate the unit without filters installed in return air system.

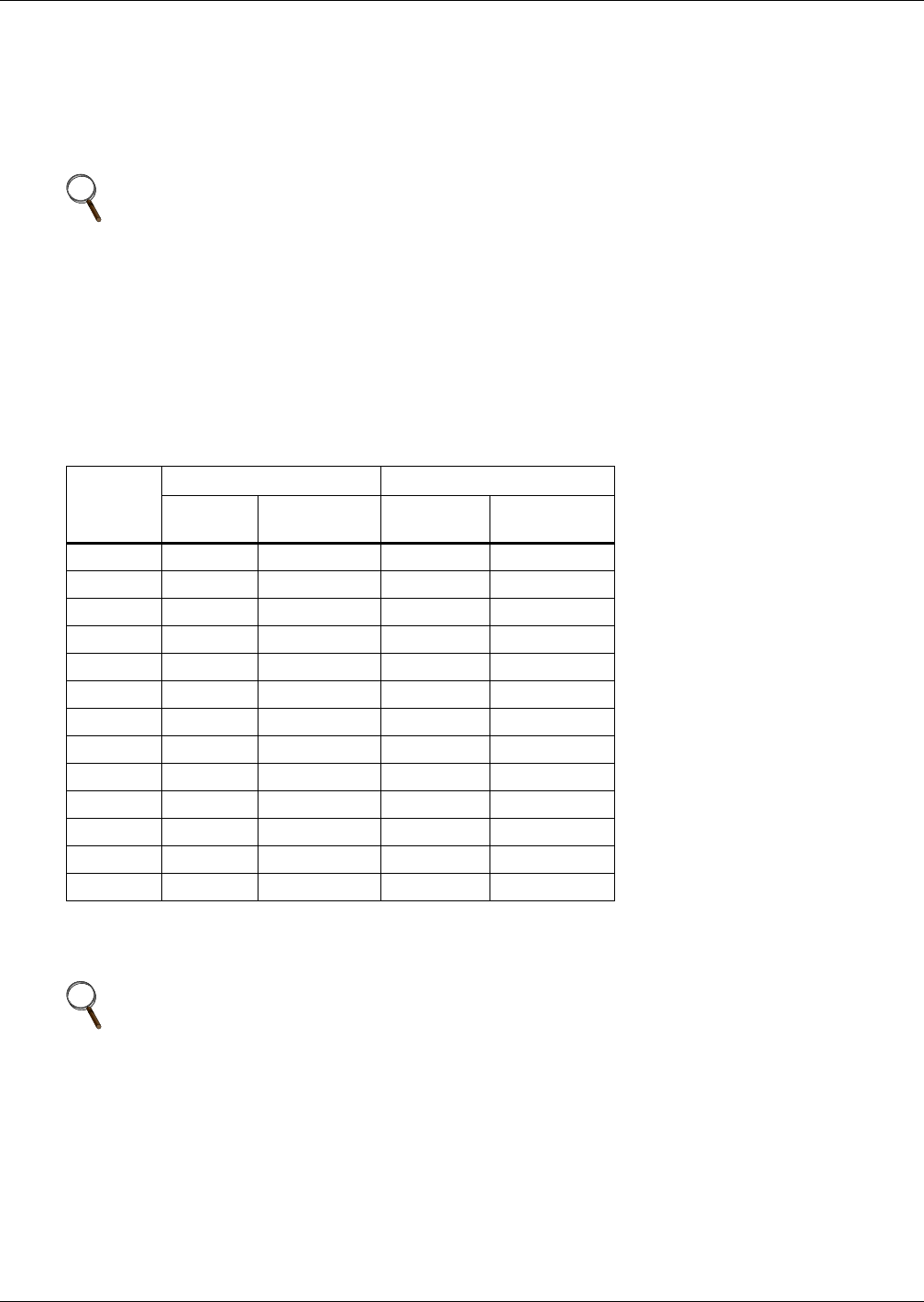

Table 5 Evaporator external static pressure (60) at 3750 CFM (6371 CMH)

Turns

Open

2 hp Motor (std) 3 hp Motor (opt)

RPM

External

Static, in. RPM

External

Static, in.

0n/a n/a 1146 1.9

0.5 n/a n/a 1125 1.8

1n/a n/a 1104 1.7

1.5 946 0.9 1083 1.6

2 922 0.8 1063 1.5

2.5 972 0.7 1042 1.4

3 899 0.6 1021 1.3

3.5 851 0.5 1000 1.2

4 828 0.4 979 1.1

4.5 804 0.3 958 1.0

5 780 0.2 938 0.9

5.5 757 0.1 917 0.8

6 733 0 896 0.7

If free-cooling or hot water coil is ordered, reduce available external static

pressure by 0.3" (8 mm). Contact Liebert Representative for other Air Volumes.

Factory setting is 0.5" (13 mm) with 2 hp motor. Field adjust to suit application.

NOTE

Maximum return air static pressure should not exceed 0.3" (8 mm) to provide proper drainage

of the unit.