INSTALLATION

PAGE 8

GAS SUPPLY HOOKUP

If using pipe other than black iron pipe see NFPA 54-National

Fire Protection Association / ANSI Z223.1-American National

Standards Institute; and local code for specific requirements

for the type of pipe used. Alternative gas piping systems such

as CSST may be used subject to local code and proper sizing.

This appliance is equipped with a flexible gas line and

fitting for a gas supply line connection. Connection can

be made using either the 3/8” NPT male fitting or, by re-

moving the fitting, to the flex line 3/8” female flare. The

flex line can be routed to the gas supply through either

the pedestal bottom or through the rear pedestal cover

depending upon the orientation of the supply line. Some

areas may have certain restrictions against the use of

flexible gas lines. Check local codes. The gas appliance

control valve has a 3/8” NPT female type inlet for the gas

supply line, if hard plumbing is required.

If the gas supply will be routed to the appliance from the

rear, the flexible gas line for hookup is readily accessible.

If the gas supply will be routed to the appliance through

the flooring, remove the rear panel. Redirect the flexible

gas line through the large hole in the center of the ped-

estal base for gas supply connection.

A gas supply line must be run to the appliance by a quali-

fied professional. The plumbing of the gas line must

comply with National Standards; NFPA 54-National Fire

Protection Association / ANSI Z223.1-American National

Standards Institute; and local code.

Gas piping must not run in or through air ducts, clothes

chutes, chimneys or gas vents, dumb waiters or elevator

shafts.

Piping should be sloped 1 / 4” per 15 feet (6mm per

4.6m) upward toward the meter from the appliance. The

piping must be supported at proper intervals every 8 to

10 ft. (2.4m to 3.1m) using suitable hangers or straps.

The gas supply line must be purged of air before it is

connected to the appliance.

An accessible, approved shut-off valve must be installed

upstream of any connector so that the appliance may be

isolated to allow service, removal, and replacement

(within six feet of the appliance per NFPA 54, or twelve

inches in some codes). A shut-off valve is provided with

this appliance.

IMPORTANT: In case emergency shut-off is required,

shut off main manual gas valve and disconnect main

power to appliance. These devices should be properly

labeled by the installer.

PRESSURE TESTING:

• The appliance main gas valve must be disconnected from the gas

supply piping system during any pressure testing of that system at

test pressures in excess of *1/2 psi (3.5 kPa).

• The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than *1/2 psi (3.5 kPa).

Make the connection to the gas supply line using the

correct fitting required to the shut-off valve.

Install a drip leg where condensates might accumu-

late. Sediment traps, like drips and collection tees, are

required to be installed. Traps collect moisture and

intercept and hold foreign objects which might block

orifices and valves. A drip leg should be installed in

vertical pipe runs to the appliance.

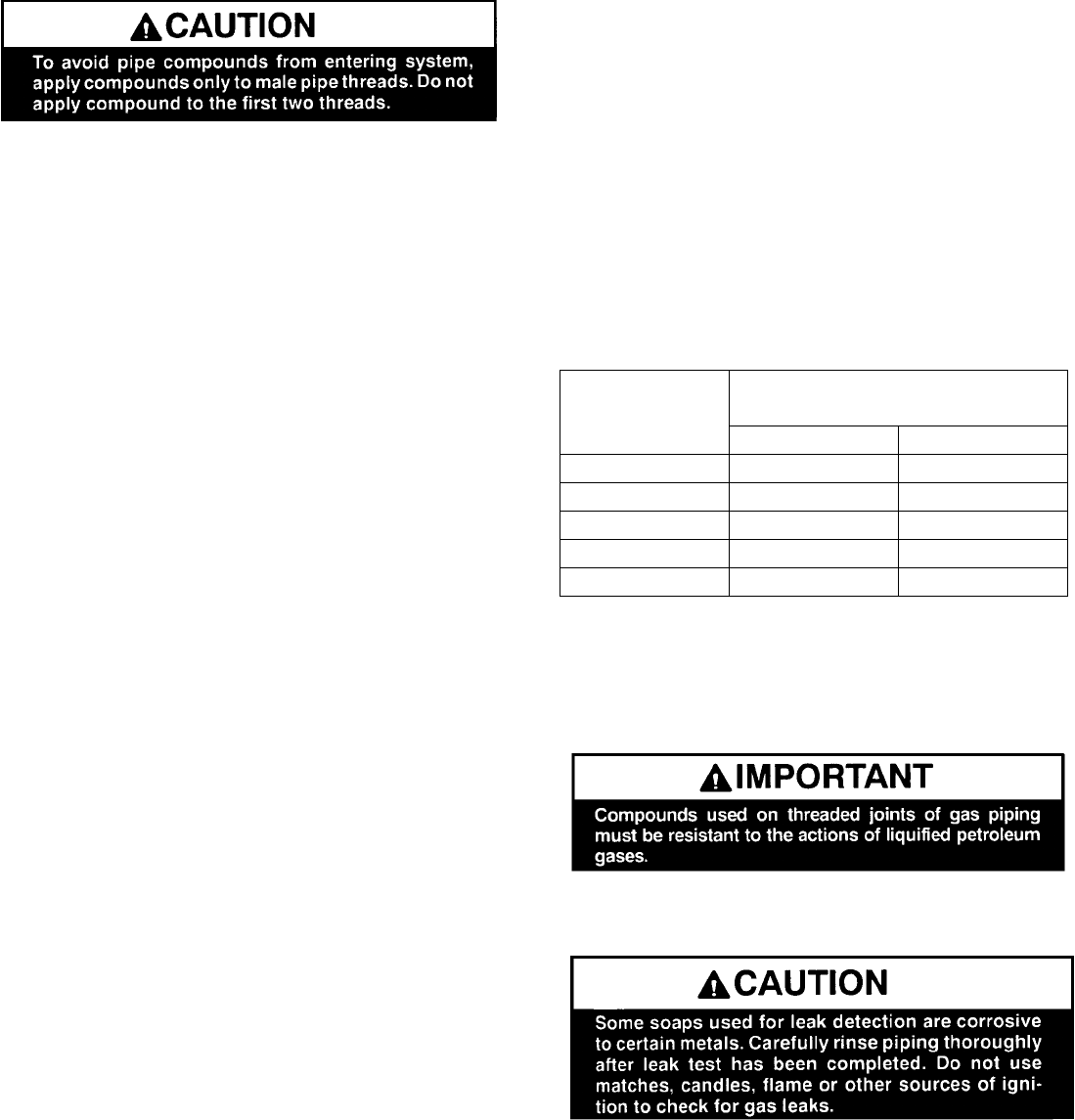

Supply Line Size Requirements

The proper gas line diameter must be used to run

from the supply regulator (at the gas company meter)

to the appliance. Never use galvanized or plastic

pipe. Refer to the table below for suggested sizing of

the gas supply line.

Suggested Sizing of

Schedule 40 Pipe Supply Line

Schedule 40 Pipe

Inside Diameter (Inches)

Schedule 40 Pipe

Length (Feet)

Natural Gas LP. Gas

0-10 1/2 3/8

10-40 1/2 1/2

40-100 1/2 1/2

100-150 3/4 1/2

150-200 3/4 1/2

Use an approved pipe sealant compound for NPT fit-

tings. After all pipe connections are made, apply

normal gas line pressure: 7.0” W.C. for natural gas;

11.0” W.C. for LP gas (propane) and use an approved

leak detection solution to test for the tightness of each

pipe connection joint.

IMPORTANT: All connections must be checked for leaks with

a leak detector or soapy water solution. Never check for gas

leakage with an open flame!

* Note: ½ psi = 14” WC (inches water column).