Page 14

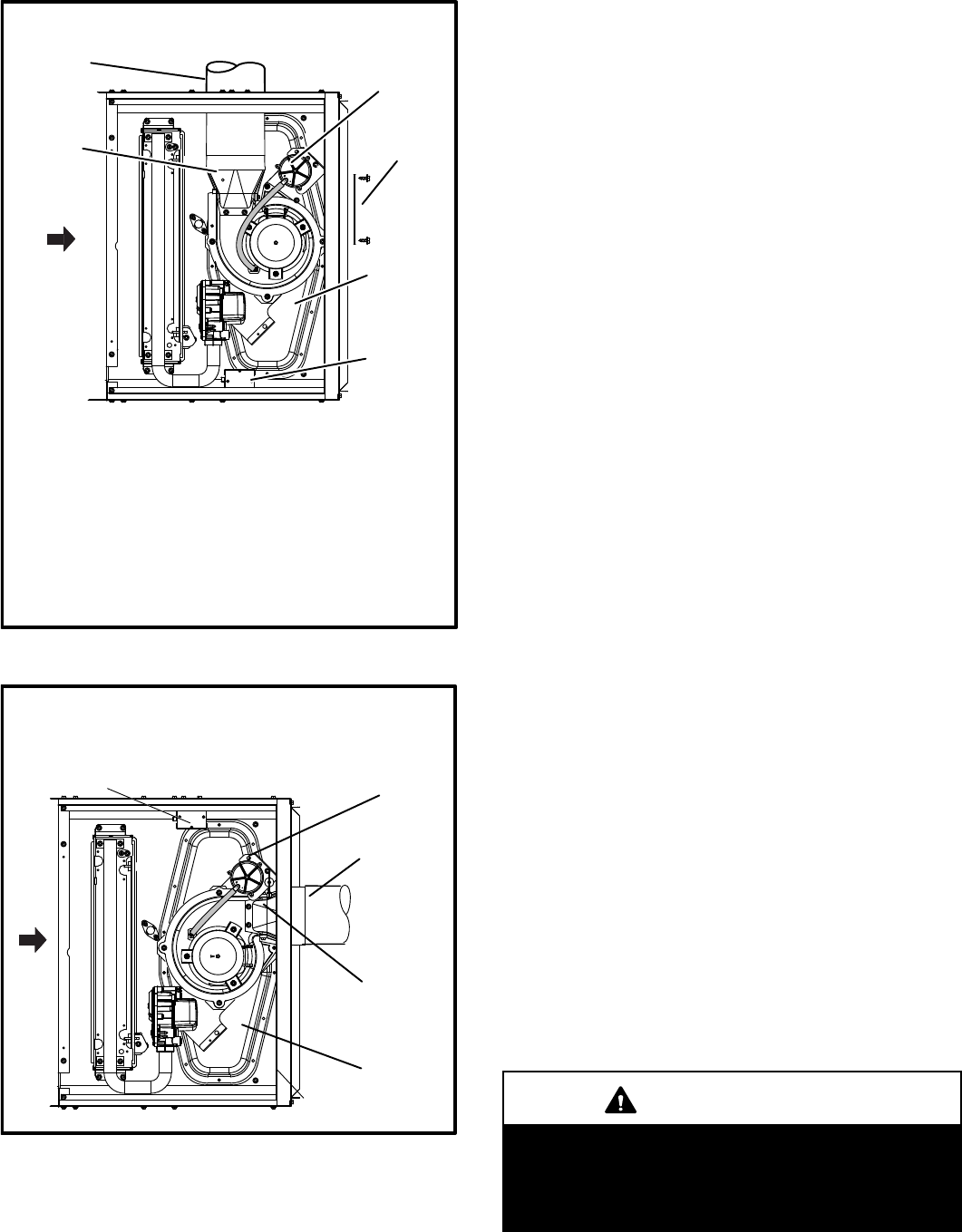

HORIZONTAL RIGHT POSITION

Top Vent Discharge

FIGURE 20

D Remove make-up box assembly (2 screws) and cut wire tie to

free make-up box wires. Re-install make-up box on other side

of cabinet.

D Re-secure make-up box wires: Either pull excess wires through

the blower compartment and secure using supplied wire tie, or

coil excess wire and secure to the gas manifold.

FLOW

AIR

Flue

Transition

Vent Pipe

Pressure Switch

Cover Plate

Make-Up Box

Collector Box

D Gas supply piping must be brought into the unit from the bot

tom in order to accommodate the flue pipe.

D Cut combustion air inducer tubing from 9” to 8” to avoid inter

ference with inducer motor

HORIZONTAL RIGHT POSITION

Side Vent Discharge - no modifications necessary

FIGURE 21

FLOW

AIR

Pressure Switch

Flue Transition

Collector Box

Make-Up Box

Vent Pipe

The EL180UHE series units are classified as fan-assisted

Category I furnaces when vertically vented according to

the latest edition of National Fuel Gas Code (NFPA 54 /

ANSI Z223.1) in the USA. A fan-assisted Category I fur

nace is an appliance equipped with an integral mechanical

means to either draw or force combustion products through

the combustion chamber and/or heat exchanger. The

EL180UHE is not approved for use with horizontal venting.

NOTE - Use these instructions as a guide. They do not su

persede local codes. This furnace must be vented accord

ing to all local codes these installation instructions, and the

provided venting tables in these instructions

The venting tables in this manual were extracted from the

National Fuel Gas Code (NFPA 54 / ANSI Z223.1) and are

provided as a guide for proper vent installation. Proper ap

plication, termination, construction and location of vents

must conform to local codes having jurisdiction. In the ab

sence of local codes, the NFGC serves as the defining doc

ument.

Use self-drilling sheet metal screws or a mechanical fas

tener to firmly secure the vent pipe to the round collar of the

flue transition. If self-drilling screws are used to attach the

vent pipe, it is recommended that three be used. Drive one

self-drilling screw through the front and one through each

side of the vent pipe and collar. See figure 22.

Install the first vent connector elbow at a minimum of six

inches (152 mm) from the furnace vent outlet. See figure

22.

Venting Using a Masonry Chimney

The following additional requirements apply when a lined

masonry chimney is used to vent this furnace.

Masonry chimneys used to vent Category I central fur

naces must be either tile‐lined or lined with a listed metal

lining system or dedicated gas vent. Unlined masonry

chimneys are prohibited. See figures 23 and 24 for com

mon venting.

A chimney with one or more sides exposed to the outside of

the structure is considered to be an exterior chimney.

An exterior masonry chimney that is not tile-lined must be

lined with B1 vent or a listed insulated flexible metal vent.

An exterior tile-lined chimney that is sealed and capped

may be lined with a listed uninsulated flexible metal vent.

If the existing chimney will not accommodate a listed metal

liner, either the chimney must be rebuilt to accommodate

one of these liners or an alternate approved venting meth

od must be found.

Insulation for the flexible vent pipe must be an encapsu

lated fiberglass sleeve recommended by the flexible vent

pipe manufacturer. See figure 23.

Refer to the tables and the venting information contained in

these instructions to properly size and install the venting

system.

IMPORTANT

Once the venting system is installed, attach the “Dis

connected Vent” warning sticker to a visible area of

the plenum near the vent pipe. See figure 22. The

warning sticker is provided in the bag assembly. Or

der kit 66W04 for additional stickers.