Page 12

Return Air Plenum

NOTE - Return air must not be drawn from a room

where this furnace, or any other gas-fueled appliance

(i.e., water heater), or carbon monoxide producing de

vice (i.e., wood fireplace) is installed.

When return air is drawn from a room, a negative pres

sure is created in the room. If a gas appliance is operating

in a room with negative pressure, the flue products can

be pulled back down the vent pipe and into the room. This

reverse flow of the flue gas may result in incomplete com

bustion and the formation of carbon monoxide gas. This

toxic gas might then be distributed throughout the house

by the furnace duct system.

In upflow applications, the return air can be brought in

through the bottom or either side of the furnace. If a fur

nace with bottom return air is installed on a platform, make

an airtight seal between the bottom of the furnace and the

platform to ensure that the unit operates properly and

safely. Use fiberglass sealing strips, caulking, or equiva

lent sealing method between the plenum and the furnace

cabinet to ensure a tight seal. If a filter is installed, size the

return air duct to fit the filter frame.

Venting

A 4-inch diameter flue transition is factory‐installed on the

combustion air inducer outlet of all models. Figure 15

shows the combustion air inducer as shipped from the

factory.

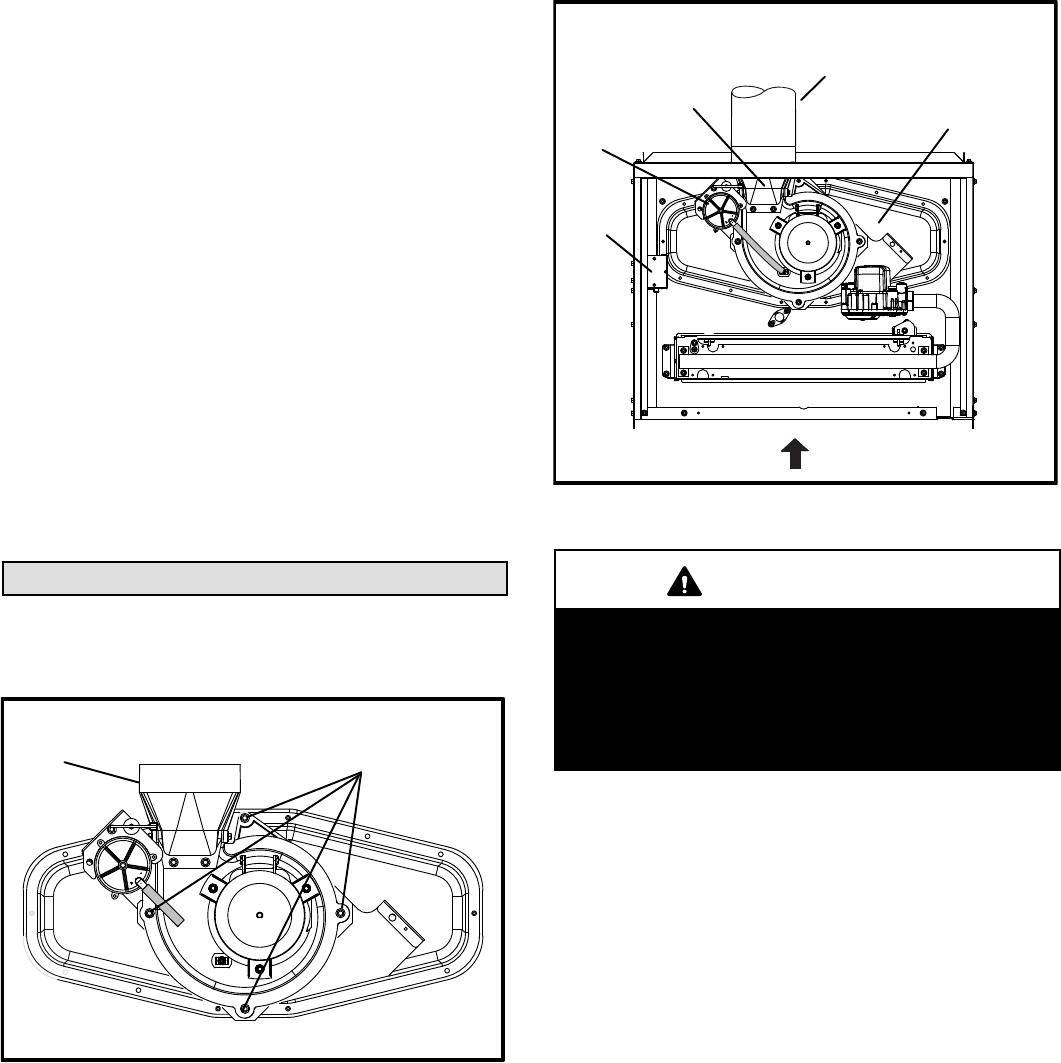

FIGURE 14

Mounting Screws Location

Mounting Screws

Flue Transition

FIGURE 15

UPFLOW POSITION

Top Vent Discharge

FLOW

AIR

Collector Box

Vent Pipe

Flue

Transition

Pressure

Switch

Make-Up

Box

IMPORTANT

The unit will not vent properly with the flue transition

pointed down in the 6 o'clock position.

The combustion air inducer may be rotated clock

wise or counterclockwise by 90° to allow for top or

side vent discharge in all applications. When the unit

is installed, the flue transition must be in the 9

o'clock, 12 o'clock or 3 o'clock position.

If necessary, reposition the combustion air inducer, pres

sure switch and/or make-up box as needed per the follow

ing steps. See figures 16 through 20.

1 - Remove the four mounting screws (figure 14) which

secure the combustion air inducer / pressure switch

assembly to the orifice plate. Lift the assembly and ro

tate it 90 degrees clockwise or counterclockwise to ei

ther the 3 o'clock position or to 9 o'clock position. Re-

secure with four screws. Gasket should be left in place.

2 - Use tin snips to cut preferred opening on the cabinet

for repositioning the flue outlet. Use the cut-out piece

as a cover plate to patch unused opening on cabinet.