Page 9

CBWMV SERIES

Electrostatic Discharge (ESD) - Precautions

And Procedures

CAUTION

Electrostatic discharge can affect electronic com-

ponents. Take precautions during air handler instal-

lation and service to protect the air handler’s elec-

tronic controls. Precautions will help to avoid con-

trol exposure to electrostatic discharge by putting

the air handler, the control and the technician at the

same electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an un-

painted unit surface, such as the blower deck, be-

fore performing any service procedure.

Refer to table 3 for field wiring.

1. Refer to the CBWMV unit’s nameplate for minimum

circuit ampacity and maximum overcurrent protection

size.

2. Install a separate disconnect switch (protected by ei-

ther fuse or circuit breaker) near the air handler so that

power can be turned off for servicing.

3. Complete the wiring connections to the equipment.

Use the provided unit wiring diagram and the field wir-

ing diagrams shown in table 3. Use 18−gauge wire or

larger that is suitable for Class II rating for thermostat

connections.

4. Electrically ground the unit according to local codes or,

in the absence of local codes, according to the current

National Electric Code (ANSI/NFPA No. 70) for the

USA and current Canadian Electric Code part 1 (CSA

standard C22.1) for Canada. A green ground wire is

provided in the field make−up box.

5. Install the room thermostat according to the instruc-

tions provided with the thermostat. See table 3 for field

wiring connections in varying applications. If the air

handler is being matched with a heat pump, refer to the

FuelMaster21

®

installation instruction.

Removeable Jumpers

Removeable Jumper DS to Y1ĊThe factory−installed

wire jumper that connects terminals DS and Y1 on the TB1

terminal strip in the control box must be removed when the

air handler is installed in a system supporting dehumidifi-

cation using a SignatureStat

t

thermostat (e.g., Humidi-

trol

®

Enhanced Dehumidification Accessory or Harmony

t

zone controls).

Removeable Jumper R to OĊThe factory−installed wire

jumper that connects TB7 (24V) terminal R to TB1 termi-

nal O must be removed when the air handler is installed in

applications which include a heat pump unit and the Fuel-

Master21

®

control board. If the jumper is left intact, termi-

nal O will remain energized, eliminating the heat mode in

the heat pump.

Removeable Jumper Y1 to Y2ĊThe factory−installed

wire jumper that connects Y1 and Y2 on the TB1 terminal

strip must be removed if two−stage cooling is used. If the

jumper is not removed the outdoor unit will only operate in

second−stage cooling.

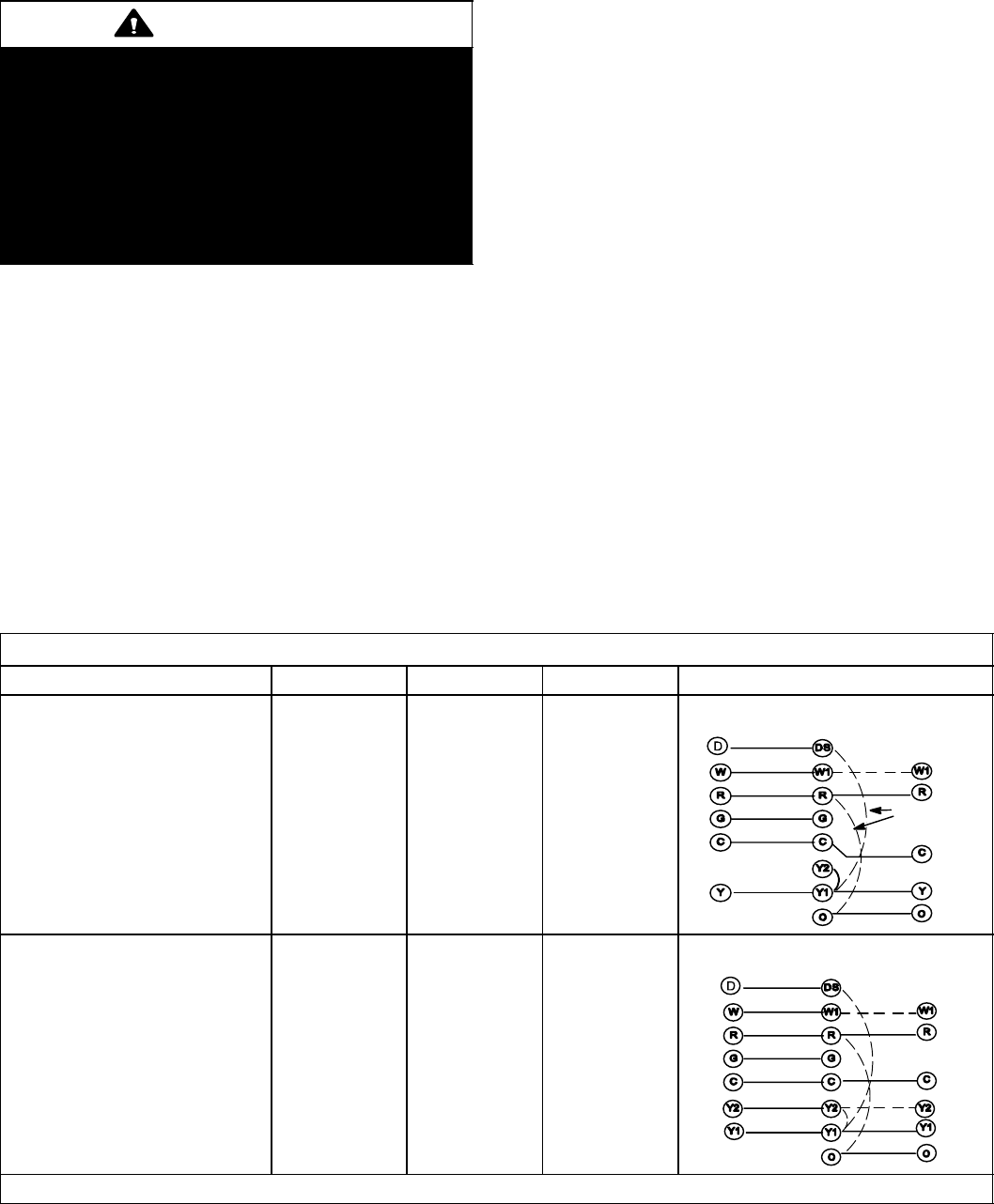

Table 3

Field Wiring Application Jumper Settings (See figure 12)

Thermostat (Application) TB1 Y1 to Y2 TB1 DS to Y1 TB1 R to O Wiring Connections

1 Heat / 1 Cool with

SignatureStatt Thermostat

[Single-Stage Heat Pump]

Yes No

(Remove)

No

(Remove)

SignatureStatt CBWMV

TERMINALS

OUTDOOR

UNIT

JUMPERS

REMOVED

2 Heat / 2 Cool with

SignatureStatt Thermostat

[Two-Stage Heat Pump (Refer

to FM21 Instructions)]

No

(Remove)

No

(Remove)

No

(Remove)

CBWMV

TERMINALS

OUTDOOR

UNIT

SignatureStatt

ALL JUMPERS

REMOVED

O" terminal used only with heat pumps.