14

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

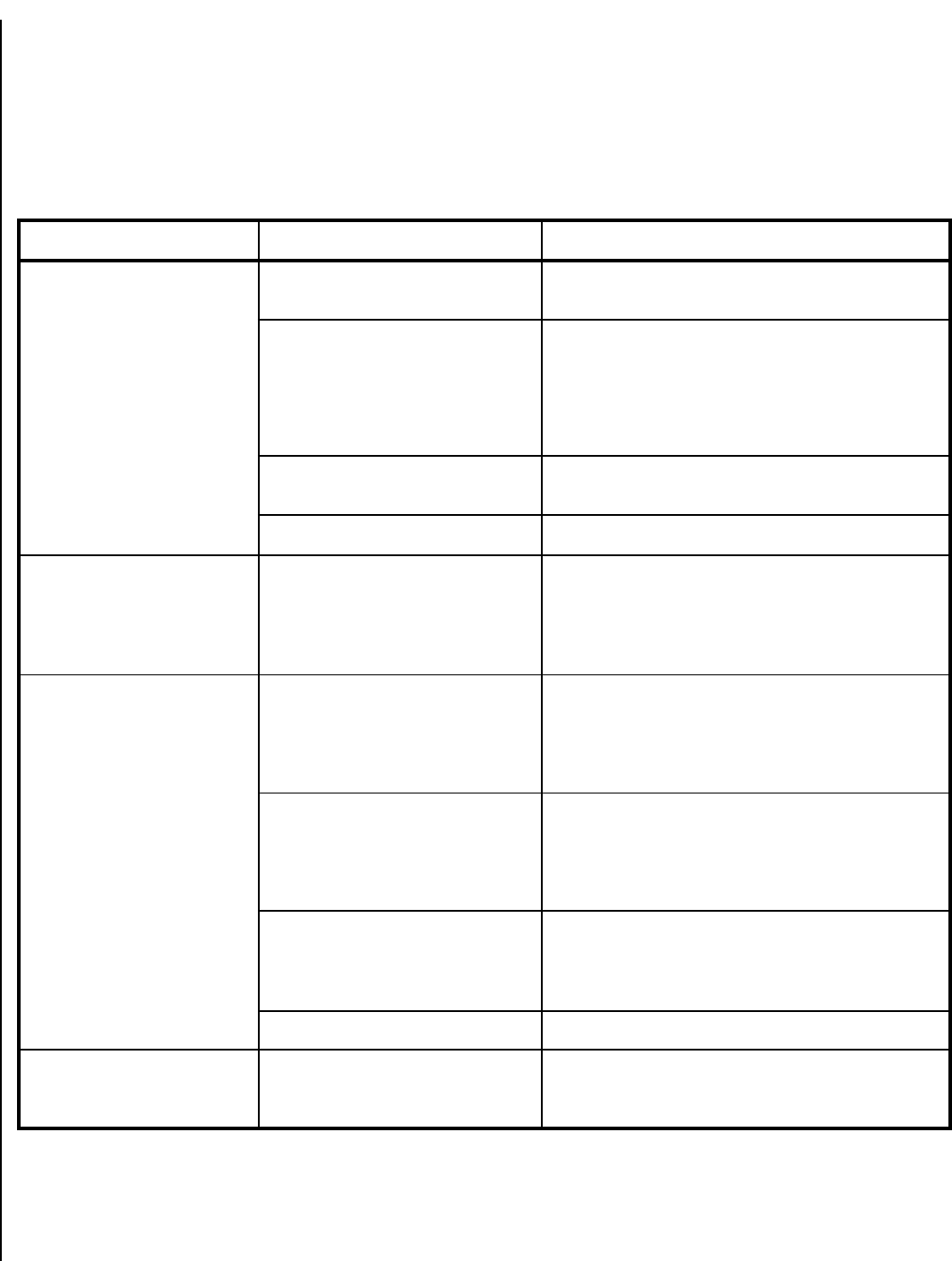

TROUBLESHOOTING THE MILLIVOLT GAS CONTROL SYSTEM

1. Spark ignitor will not light

pilot after repeated

triggering of ignitor button.

2. Pilot will not stay lit after

carefully following the

lighting instructions.

3. Pilot burning, no gas to

burner, Valve knob “ON,”

Wall Switch “ON.”

4. Frequent pilot/burner outage

problem.

CORRECTIVE ACTIONSYMPTOM

A. Defective ignitor

(no spark at electrode).

B. Defective or misaligned electrode

at pilot (spark at electrode).

C. Gas supply pressure errant.

D. Pilot orifice plugged.

A. Defective pilot generator

(thermogenerator).

A. Damper closed or Damper Switch

defective.

B. Wall switch or wires defective.

C. Thermopile may not be generating

sufficient millivoltage.

D. Plugged burner orifice.

A. Pilot flame may be too low or

blowing (high) causing the pilot/

valve safety to drop out.

Check for spark at electrode and pilot; if no spark and

electrode wire is properly connected, replace ignitor.

Using a match, light pilot. If pilot lights, turn off pilot and

trigger the ignitor button again. If pilot lights, an improper

gas mixture caused the bad lighting and a longer purge

period is recommended. If pilot will not light – check gap at

electrode and pilot - should be ¹⁄₈" to have a strong spark. If

gap measures ¹⁄₈", replace pilot

(Figure 9 ).

Check inlet gas pressure. It should be within the limits as

marked on the rating plate.

Clean or replace pilot orifice.

Check pilot flame, it must impinge on thermogenerator

(Figure 9

)

. Clean and/or adjust pilot for maximum flame

impingement on thermogenerator. Ensure that the connec-

tion between the valve and thermogenerator are tight and

secure.

Ensure damper control lever is locked in the open position,

all the way to the right. If the damper control lever is locked

in the open position troubleshoot through Steps B., C. and

D. below. If the main burner will still not light, determine if

the damper switch is defective and replace if necessary.

Check wall switch and wires for proper connections. Jumper

wire across terminals at wall switch, if burner comes on,

replace defective wall switch. If okay, jumper wires across

wall switch wires at valve, if burner comes on, wires are

faulty or connections are bad.

Check thermopile with millivolt meter. Take reading at ther-

mopile terminals of gas valve. Should read 325 millivolts

minimum with optional wall switch “OFF.” Replace faulty

thermopile if reading is below specified minimum.

Check burner orifice for stoppage and remove.

Clean and/or adjust pilot flame for maximum flame impinge-

ment on thermogenerator

(Figure 9

)

.

POSSIBLE CAUSES

Note: Before troubleshooting the gas control system, be sure external gas shut off valve (located at gas supply inlet) is in

the “ON” position.

Important: Valve system troubleshooting should only be accomplished by a qualified service technician.