536636-UIM-D-1211

6 Johnson Controls Unitary Products

TXV METERING DEVICES

If the model (C) number is of the following format: 4F, 4G, 4H, 4J,

and 4K will have the coil with R410A TXV metering device installed at

the factory.

If the model (C) number is of the 3X model series:

The coil will require an orifice or R410A TXV to be installed in the field.

Refer to installation manual with TXV kit. It is recommended to install a

orifice or TXV kit prior to brazing line sets.

Please refer to Outdoor Unit Tech Guide to verify which metering device

is installed in this coil and that this is a valid system match for the AC or

HP unit installed.

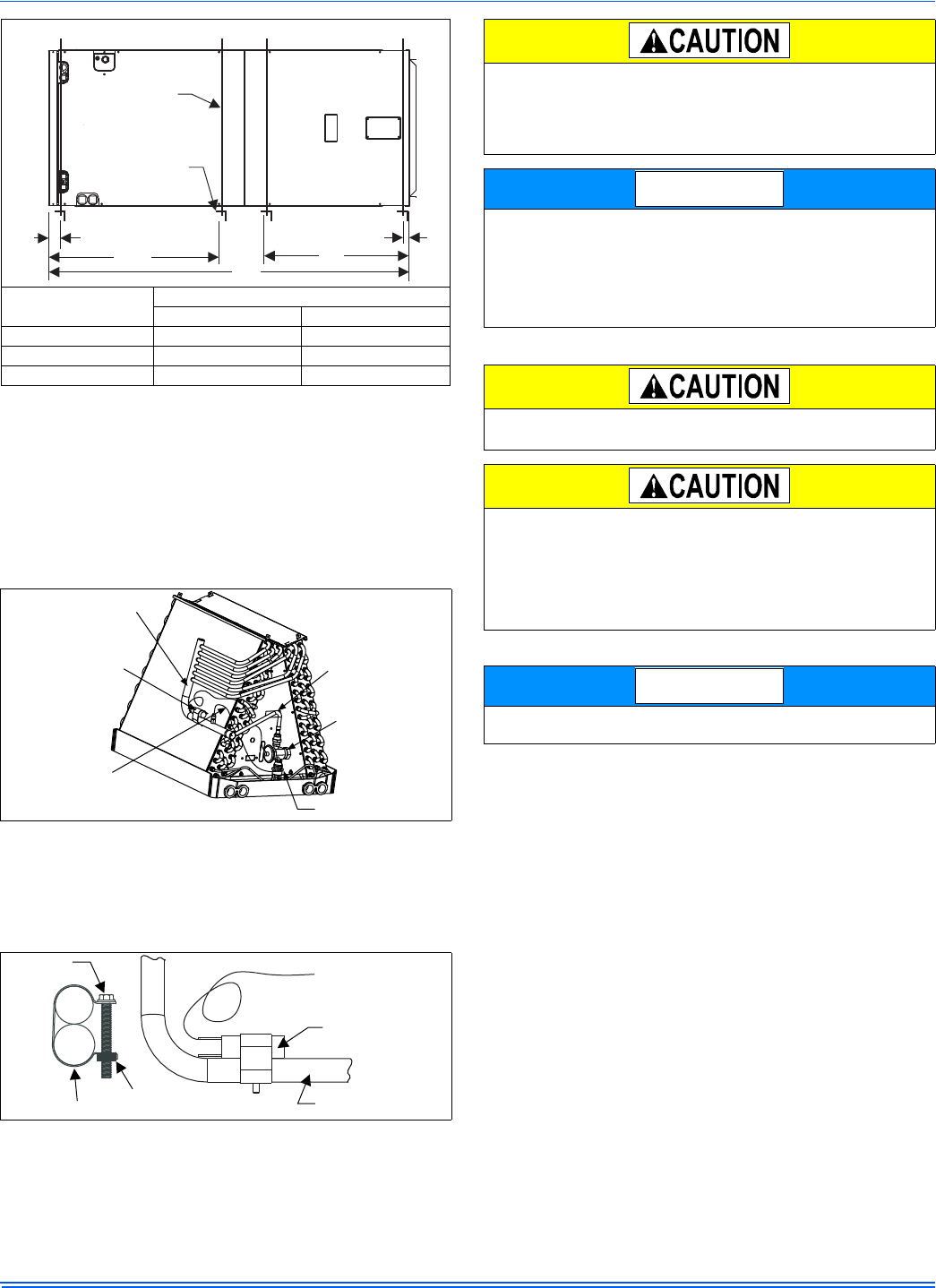

The temperature sensing bulb is attached to the coil suction header

line.

REFRIGERANT LINE CONNECTION

Connect lines as follows:

1. Suction and liquid line connections are made outside the cabinet.

Leave the tubing connection panel attached to the cabinet with the

tubes protruding through it. Coil access panel should be removed

for brazing. The lines are swedged to receive the field line set

tubes.

2. Cut the end of the suction tube using a tube cutter. Place the tube

cutter as close as possible to the end of the tube to allow more

space for the connection and brazing of the suction line.

3. Remove the heat shield from the Customer Packet, soak in water,

and install over coil tubing to prevent overheating of cabinet.

4. Wrap a water soaked rag around the coil connection tubes inside

the cabinet to avoid damaging the TXV bulb.

5. Remove grommets where tubes exit the cabinet to prevent burning

them during brazing.

6. Purge refrigerant lines with dry nitrogen. Follow outdoor unit braz-

ing instructions.

7. Braze the suction and liquid lines.

8. Remove the heat shield.

9. Re-attach the grommets to the lines carefully to prevent air leak-

age.

10. Attach the coil access panel to the cabinet.

Refer to Outdoor unit Installation Manual for evacuation, leak check and

charging instructions.

Lines should be sound isolated by using appropriate hangers or strap-

ping.

All evaporator coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or

equivalent. DO NOT use soft solder.

Units

(Nominal Tons)

Dimension

WW XX

24B 20 46

36C 24 52

AV*48D, 60D 28 57

FIGURE 8: Typical Horizontal Installation

FIGURE 9: TXV

FIGURE 10: Proper Bulb Location

WW

XX

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTALAPPLICATIONS

2

1-1/2

MIN. 1-1/2” x 1-1/2”

Angle Recommended

length 26” minimum with

2” clearance on both

sides ofAir Handler

MIN. 3/8”

THREADED ROD

YY

VAPOR

LINE

THERMAL

EXPANSION

VALVE BULB

(Required insulation

not shown for clarity)

THERMAL

EXPANSION

VALVE

DISTRIBUTOR BODY

LIQUID

LINE

TXV

EQUALIZER

LINE

TXV BULB

(Cover completely

with insulation)

SCREW

CLAMP

NUT

SUCTION LINE

COIL UNDER PRESSURE.

Relieve pressure by depressing schrader core. Coil may have factory

installed TXV or may require orifice or TXV to be added. See outdoor

unit documentation for correct orifice or TXV to be used. Refer to coil

nameplate for TXV identification for this unit.

The coil should be open to the air for no more than 2 minutes to keep

moisture and contaminates from entering the system. If the coil can-

not be installed into the refrigeration system in that time, the ends

should be temporarily closed or plugged. For a short term delay, use

masking tape over the ends of the copper tubing to close the tube to

the air. For a longer term delay, use plugs or caps. There is no need

to purge the coil if this procedure is followed.

Coil is under inert gas pressure. Relieve pressure from coil by

depressing schrader core.

Dry nitrogen should always be supplied through the tubing while it is

being brazed, because the temperature required is high enough to

cause oxidation of the copper unless an inert atmosphere is provided.

The flow of dry nitrogen should continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only

low pressure dry nitrogen is introduced into the tubing. Only a small

flow is necessary to displace air and prevent oxidation.

Route the refrigerant lines to the coil in a manner that will not obstruct

service access to the coil, air handling system, or filter.

NOTICE

NOTICE