898841-UIM-B-0113

Johnson Controls Unitary Products 17

LEAK TEST AND EVACUATION

Air and moisture remaining in the refrigerant system will have undesir-

able effects as indicated below:

1. Pressure in the system rises.

2. Operating current rises.

3. Cooling or heating efficiency drops.

4. Moisture in the refrigerant circuit may freeze and block capillary

tubing (30 kBtu size only).

5. Water may lead to corrosion of parts in the refrigeration system.

The line set between the indoor and outdoor units must be leak tested

and evacuated to remove any non-condensable and moisture from the

system.

AIR PURGING WITH VACCUM PUMP

Be sure to use a vacuum pump with counter-flow prevention function to

make oil inside the pump does not flow back into the system pipes

when the pump stops.

1. Run the vacuum pump.

2. Connect the charge hose from the manifold valve to the service port

of the gas side packed valve.

3. Connect the charge hose to the port of the vacuum pump.

4. Open fully the low pressure side handle of the gauge manifold

valve.

5. Operate the vacuum pump to begin evacuating.

6. The operation time for evacuation varies with the lineset length and

capacity of the pump. Allow the pumpto operate until the system

has been evacuated downto 300 microns. Allow the pump to con-

tinue running foran additional 15 minutes.

7. Turn off the pump and leave the connection secured to the suction/

vapor 2-way service port. After five minutes, if the system fails to

hold 500 microns or less, check all connections for tight fit and

repeat the evacuation procedure.

8. Close the low pressure valve handle of gauge manifold.

9. Open fully the valve stem of the packed valves (both gas and liquid

sides).

10. Remove the charging hose from the service port.

11. Securely tighten the caps on the packed valves.

ADDING REFRIGERANT FOR LONGER LINE SET

1. Open the low side manifold gauge valve and weigh in liquid refriger-

ant. Use Table 6 to calculate the correct weigh-in charge.

2. Close manifold gauge valves.

LEAK TEST

Use the following procedure to test for system leaks:

1. Connect the manifold gauge set and dry nitrogen gas cylinder to the

suction/vapor service port. See Figure 30.

2. Open valve on nitrogen cylinder.

3. Pressurize the system to no more than 150 PSIG with dry nitrogen.

4. Check for leaks using soapy water.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder

• Relieve the nitrogen pressure by: loosening the charge hose con-

nector at the nitrogen cylinder.

• When the system pressure is reduced to normal, disconnect the

hose from the cylinder.

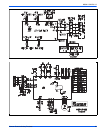

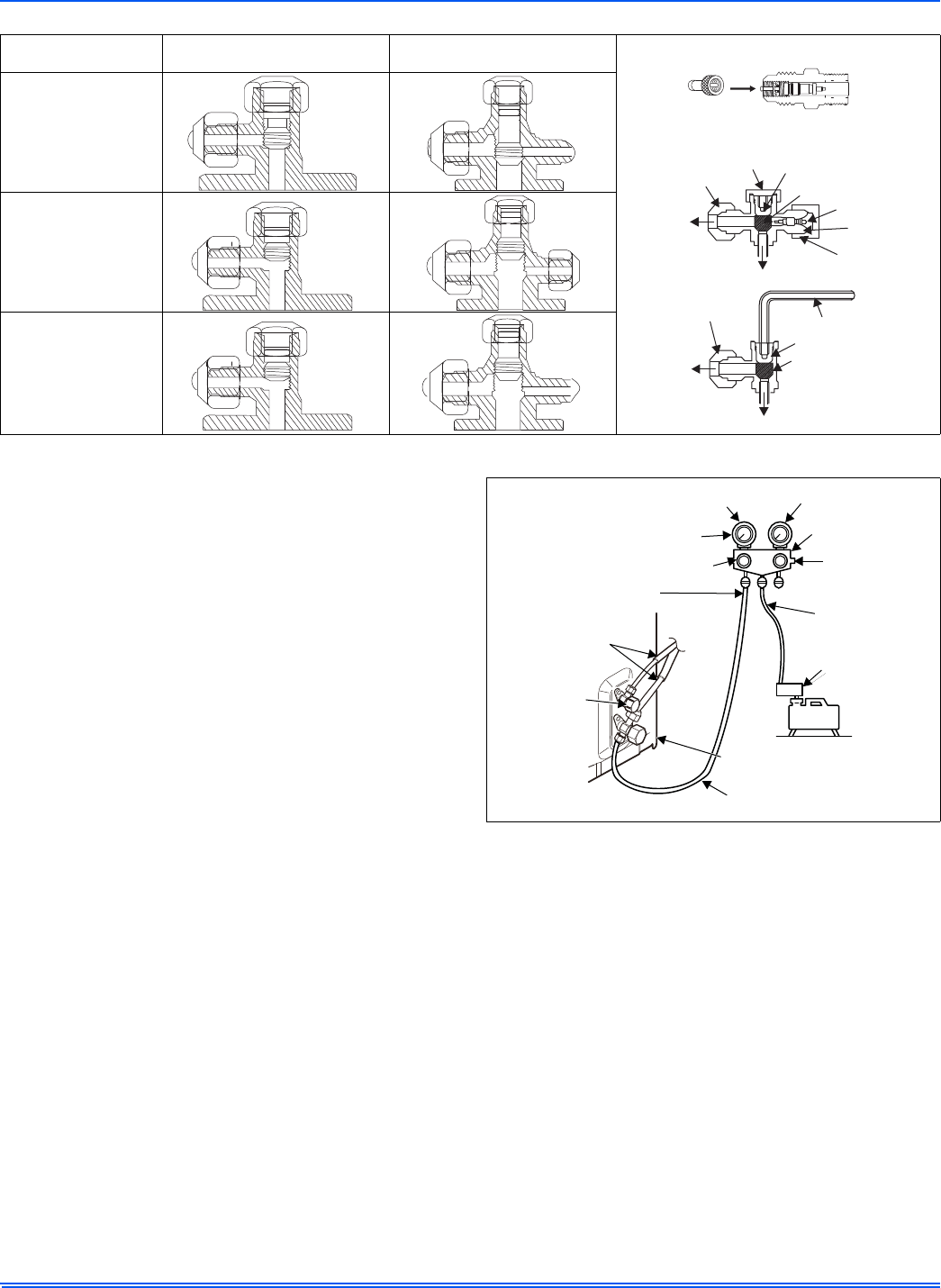

Action

Shut-off

2-way Valve

Suction/Vapor

2-way Service Valve

Evacuating with a

vacuum pump

Outdoor unit running

Checking pressure

and adding refrigerant

FIGURE 38: Service Valve Operation

SUCTION/VAPOR

2-WAY SERVICE VALVE

HOSE WITH

SCHRADER VALVE

PUSH

REQUIRES FIELD PROVIDED 5/16” FEMALE

FLARE TO 1/4” MALE FLAREADAPTER.

VALVE CAP

OPEN POSITION

CLOSED POSITION

SCHRADER CORE

FLARE CAP

TO LINE SET

SERVICE

PORT CAP

SERVICE

PORT

TO OUTDOOR UNIT

FLARE CAP

ALLEN WRENCH (5MM)

OPEN POSITION

CLOSED POISTION

TO OUTDOOR UNIT

TO LINE SET

CLOSED

FULLY

OPEN

FULLY

OPEN

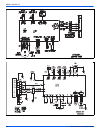

FIGURE 39: Gauge Set Connections for Test Leaks, Evacuation

Charging

COMPOUND

PRESSURE

GAUGE

PRESSURE GAUGE

-101kPa

(-76cmHg)

HANDLE LOW

MANIFOLD VALVE

HANDLE HIGH

(KEEP FULL

CLOSED)

CHARGE HOSE

CHARGE HOSE

CONNECTING

PIPE

PACKED VALVE

ATLIQUID SIDE

VACUUM PUMP

ADAPTER FOR

COUNTER-FLOW

PREVENTION

PACKED VALVEAT GAS SIDE

SERVICE PORT

SCHRADER CORE

VACUUM

PUMP