GENERAL

7

Concord CXSi/H - Installation & Servicing

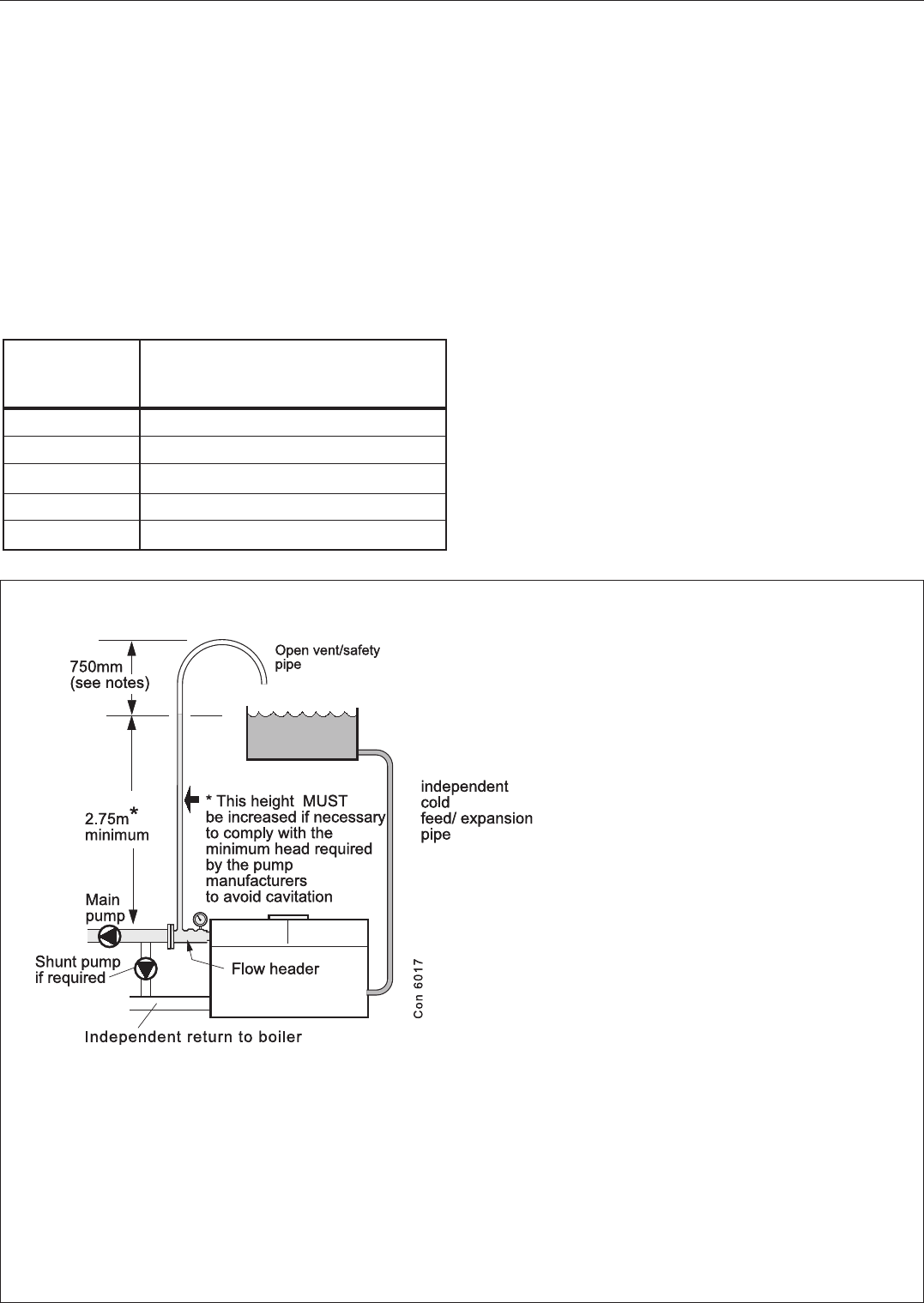

Note. This diagram does not show safety valves, water flow

switches, etc., necessary for the safe operation of the system.

3

OPEN VENTED SYSTEMS - minimum static head requirements

Particular reference should be made to BS. 6644: Section 2; Subsection

10 and Guidance note PM5 "Automatically controlled steam and hot

water boilers" published by the Health and Safety Executive.

The information and guidance given below is not intended to override any

requirements of either of the above publications or the requirements of

the local authority, gas or water undertakings.

Other British Standards applicable are BS.5422 and BS.6700.

The information provided is based on the

following assumptions:

1. The open vent MUST be brought to either

the 1

1/2" BSP tapping on the flow header

provided or to the unused 2" BSP flow

tapping at the top rear of the boiler.

2. An independent cold feed/expansion pipe

connection is made to the LH lower front

connection. Cold feed/expansion pipe

connections made to the pumped system

return will result in an increase in the static

head requirement, caused by the

additional resistance of the distributor tube.

Surging may also increase.

3. The maximum flow rate through the boiler

is based on a temperature difference of

11°C at full boiler output and the circulating

pump is positioned in the flow to the

system.

4. The boiler is at the highest point of

circulation in the system. Systems

designed to rise above the boiler flow

tappings will automatically require a

minimum static head higher than that

shown.

5. The position of the open vent/safety pipe

above the expansion cistern water level is

given as a guide only. The final position will

depend upon the particular characteristics

of the system. Pumping over of water into

the expansion cistern must be avoided.

WATER TREATMENT FOR HOT WATER AND

HEATING BOILERS

There is a basic need to treat the water contained in all heating and

indirect water systems, particularly open vented systems. It is

assumed, incorrectly, that because boilers are operating in

conjunction with what is apparently a closed circuit an open vented

system will not, under normal circumstances, allow damage or loss

of efficiency due to hardness salts and corrosion once the initial

charge of water has been heated up a few times.

1mm of lime reduces the heat transfer from metal to water by 10%.

In practice the deposition of these salts is liable to cause noises

from the boiler body or even premature boiler failure. Corrosion

and the formation of black iron oxide sludge will ultimately result in

premature radiator failure.

Open vented systems are not completely sealed from the

atmosphere if proper venting and expansion of system water is to

be achieved. The same tank is used to fill the system with water

and it is through the cold feed pipe that system water expands into

the tank when the boiler passes heat into the system. Conversely,

when the system cools, water previously expanded is drawn back

from the tank into the system, together with a quantity of dissolved

oxygen.

Even if leakage from the heating and hot water system is eliminated

there will be evaporation losses from the surface of the tank which,

depending upon ambient temperature, may be high enough to

Table 4 - Flow rates for fully pumped systems

Boiler Minimum flow rates for a

temperature difference of 35°C (63°F)

l/s g.p.m.

CXSi 110/H 0.75 9.9

CXSi 120/H 0.82 10.8

CXSi 140/H 0.96 12.7

CXSi 160/H 1.10 14.6

CXSi 180/H 1.24 16.4

PUMP POSITIONS

Whenever practically possible the circulating pump(s) should be

positioned so that it pressurises the system being served. The

vertical distance between the pump(s) and any cold feed and

expansion cistern MUST comply with the pump manufacturers

requirements, in order to avoid cavitation. These requirements

override the information given in Frame 3 if the static head required

for the pump(s) exceeds that required for the boiler.

MINIMUM FLOW OF WATER - Refer to Table 4

The system design must provide for an adequate flow rate through

the boiler at all times when the boiler is firing. The minimum flow

rate should correspond to a temperature difference across the boiler

flow and return of 35°C (63°F), assessed at catalogue rating.

157294-3.pmd 11/8/2005, 9:58 AM7