EXCEL 10 FCU CONTROLLER LNS PLUG-INS USER GUIDE

EN2B-0285GE51 R0909

13

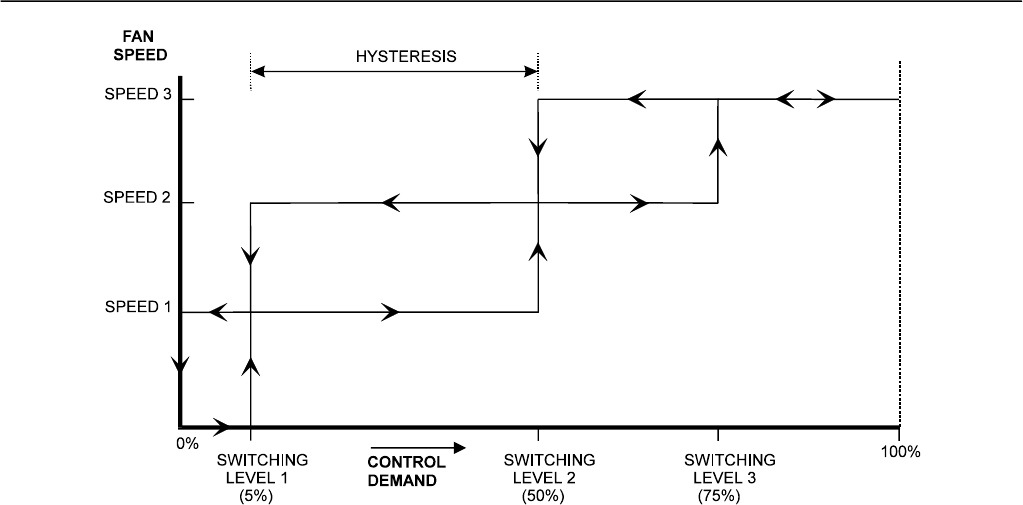

Fig. 9. Three-speed fan switching and hysteresis, cooling mode (defaults for switching levels shown)

Type of Heating and Cooling Equipment

Excel 10 FCU Controllers can operate with either two-pipe or

four-pipe systems. A two-pipe system requires a changeover

input to the controller (hardware or network input).

Excel 10 FCU Controllers can operate with a variety of

actuators for heating and cooling equipment. Floating

actuators can be used; this requires that the valve run time be

specified during configuration of the controller.

The actuator runtimes can be configured in the range 20 sec

to 600 sec in steps of 1 second.

Valves will be synchronized by driving the valve fully closed

(150% of the valve run time) under the following conditions:

• whenever the control level reaches 0% or less;

• at power-on;

• whenever the occupancy status changes to a lower mode,

e.g., from occupied to standby or unoccupied;

• when synchronization has not taken place within the last

24 hours.

Once synchronization has been completed, the output control

will be returned to the normal control loop.

Valve action can be configured as either direct or reverse.

When in a two-pipe system with a changeover input, a floating

actuator can be used which has the middle position (50%) as

the zero energy position. The cool range is then 0 to 50% and

the heat range 50 to 100%. The output must be configured as

floating-mid.

Multi-stage systems can be controlled with up to three

different stages of heating/cooling control. Switching levels

are specified in % of control level (see Fig. 10) as is a

hysteresis setting which applies to all switching levels.

Heating and cooling switching levels and hysteresis are

specified separately. Min. OFF times can be configured, and

for one-, two- and three-stage systems, a min. ON time can

also be configured.

PWM electronic valves and thermal actuators can also be

connected and can be configured as either direct or reverse

action. The cycle time must be specified during configuration.

In the case of PWM valves, the zero and full positions must

also be configured.

Additionally, the W7754K1001 features an extra socket

(located to the left of the terminal blocks) containing a digital

output suitable for connection to a solid-state relay employed

for low-voltage PWM control in high-current electric reheat

applications.