MV100 ELECTRIC CONTROLLERS T100, T200 THERMOSTATIC CONTROLLERS AND V2000 RADIATOR VALVES

62-3048—2 12

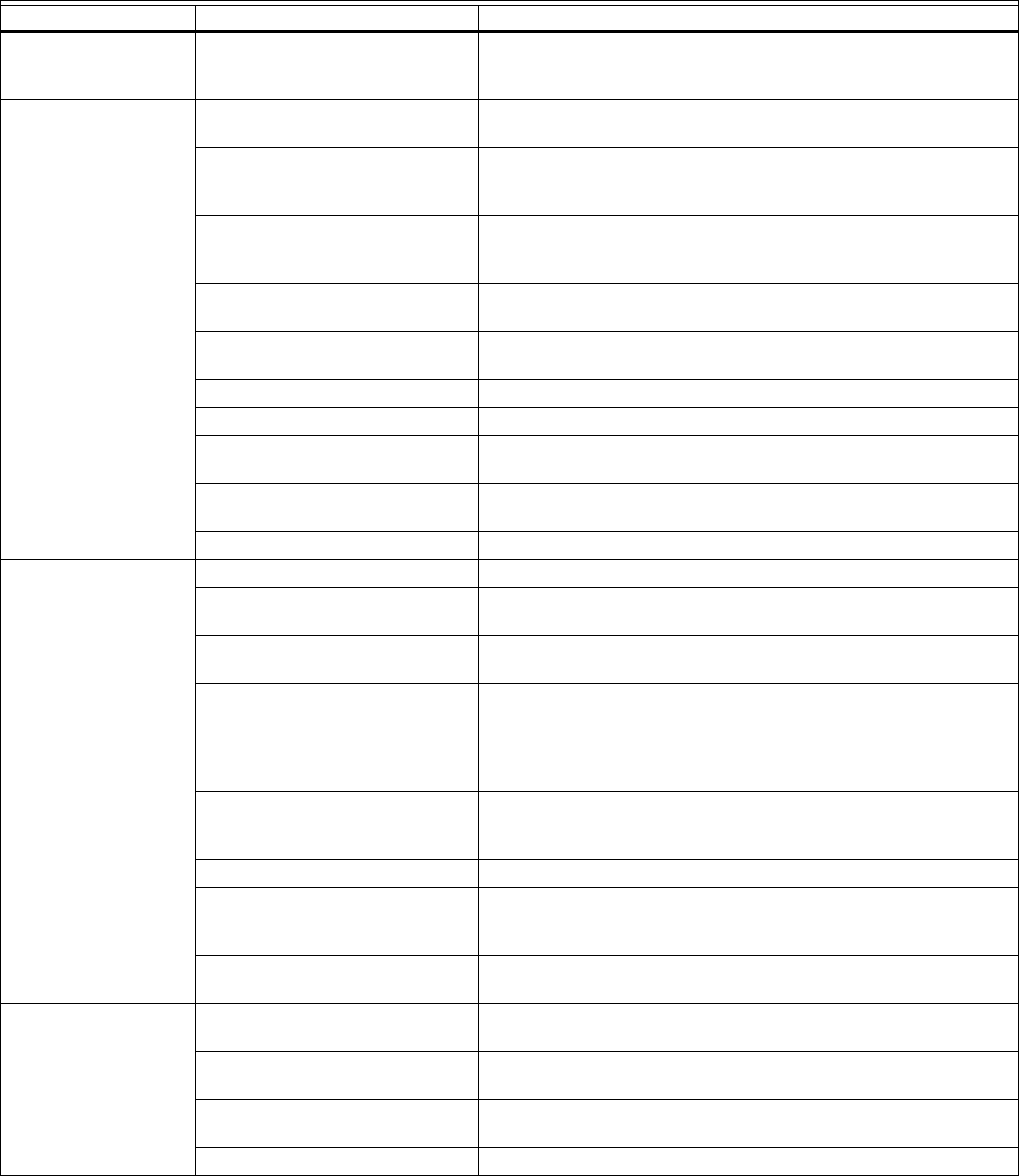

TROUBLESHOOTING

Refer to Table 6 for troubleshooting details.

Table 7. T100/V2000 Troubleshooting.

Symptom Possible Cause Solution

Not all sections of the

radiator are heating.

Many radiators are oversized and

not all sections heat to maintain

the desired temperature.

System is operating properly.

Underheating Sensor in the wrong location. Change the sensor location or change the control type. See

Installation Instructions.

T100A,M Controller mounted in a

vertical position above the hot

pipe.

Mount the T100A,M horizontally, or switch controller to a T100F.

Excess capillary tubing coiled

above or too close to the heat

source.

Coil excess capillary tubing below or away from the heat source.

Flow through the valve is in the

wrong direction.

Check the arrow on the valve body. It should be in the direction of

the flow. Change the valve direction or flow direction.

Inadequate system temperature or

pressure.

Check boiler operating and limiting controls, circulating pump, and

isolating valves.

Defective steam traps. Repair or replace the traps.

Airlock in the hot water system. Fully open the valve to allow air to pass. Install vents.

Scale or debris blocks flow. Flush the system. Do not use oil-based additives. Clean strainer

insert in steam applications.

Heating cabinet dampers are

closed.

Open or remove the dampers.

Single-pipe: Blocked vent. Remove and inspect vent. Replace if necessary.

Overheating Sensor in the wrong location. Change sensor location or change control type.

Control not properly installed. Check for bosses and grooves, reset actuator on valve and tighten

knurled ring to valve body.

Capillary tube broken, kinked or

bent sharply.

Replace control.

Dirt or scale under the seat

prevents tight shutoff.

Remove the control from the valve body, allowing valve to open

fully and flush away scale and debris. Reinstall control. Turn fully

clockwise. If the valve does not close fully, remove the control and

cartridge (see Cartridge Replacement section). Always use a

strainer insert in steam applications.

Flow through the valve is in the

wrong direction, damaging the

valve seat.

Check the arrow on the valve body. It should correspond to the flow

direction. Change the valve direction or flow direction. Remove

valve cartridge and inspect seat disk for damage.

Defective steam traps. Repair or replace traps.

Excessive differential pressure

forces the valve open (hot water

systems).

Install differential pressure regulator (D146A) to maintain less than

15 psi (103 kPa) differential between the supply and return pipes.

Single-pipe: Insufficient air in

system.

Check boiler cycling and system vacuum breakers. Repair or

replace breakers as necessary.

Chattering or knocking. Flow through the valve in the

wrong direction.

Check the arrow on the valve body. It should correspond to the flow

direction. Change the valve direction or flow direction.

Vacuum in the system. Steam—check traps and vents.

Hot water—check expansion tank operation and location.

Excessive differential pressure. Install differential pressure regulator (D146A) to maintain less than

15 psi (103 kPa) differential between the supply and return pipes.

Bent piping. Ensure adequate space for piping.