Reciprocator Repair

14 312350E

10. Clean all sealant from threads of any part you are

reusing. Apply Loctite

®

242 or Perma-Loc

®

115

thread sealant to first two or three internal threads of

valve assembly (31).

If you removed capscrew (51) apply thread sealant

to first two or three internal threads of valve stop

(26). Apply primer to external threads of valve

sleeve (29). Let dry for three or four minutes.

Assemble. Remove excess sealant.

11. Remove o-ring (13*) from bottom of spool valve (31)

and replace it with a new o-ring.

12. Use a spanner wrench to screw piston (22) onto

displacement rod (34). Torque to 40 to 48 ft-lb (54 to

65 N.m).

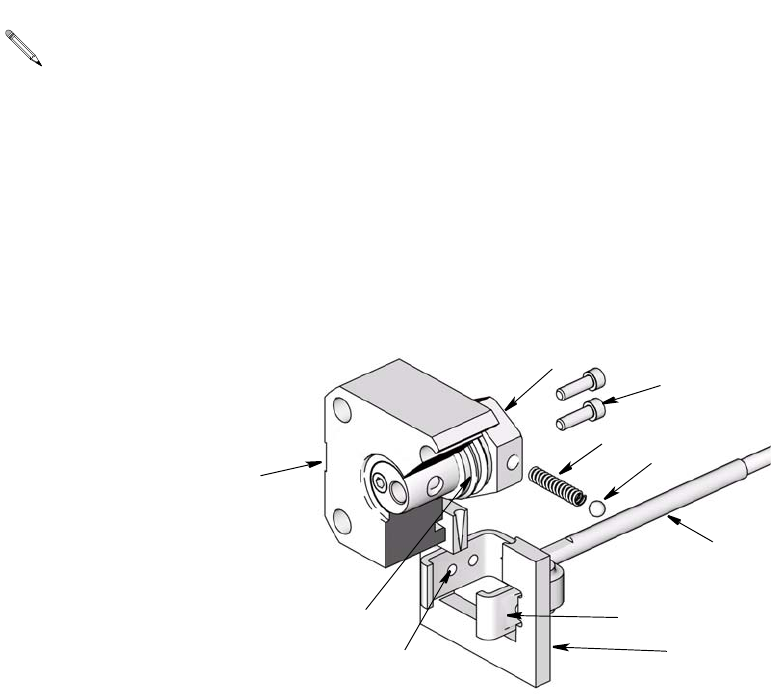

See F

IG. 10 for steps 13-16.

13. Lay Assembly A and Assembly B on work bench.

14. Slide Assembly B in into center of tool (D), Part No.

189305. Align upper detent holes (C) of yoke (9)

with center line of tool (D).

15. Insert spring (6) and one ball (7) into valve stop (26)

of Assembly A. Tilt valve stop and start guiding it

into tool (D), making sure ball is sliding into rounded

slot in tool (D). Place other ball at the other end of

spring and push it in with your thumb while rotating

valve stop (26) until spring is horizontal and balls

are in place. Continue holding this assembly

together.

16. Slide valve stop assembly down into tool. Make sure

balls (7) snap into upper set of holes (C) in yoke (9)

and curved ends of guide clamp have engaged

valve sleeve (29) groove. Slide tool (D) back over

rod (12) to remove it.

F

IG. 10

Allow 24 hours to cure before operating

reciprocator.

9

ti10606a

12

D

C

7

6

Assembly A

Assembly B

31

26

51

29