Reciprocator Repair

12 312350E

Reciprocator Repair

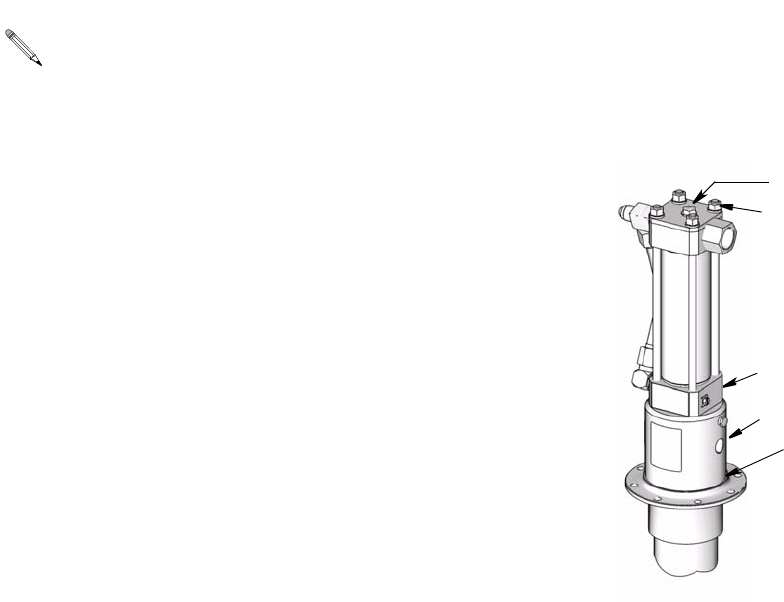

See FIG. 7 and FIG. 9 and Reciprocator Parts, page 18.

Drain Oil Out of Reciprocator

Before you begin, drain oil out of reciprocator.

1. Relieve pressure, page 7.

2. Place reciprocator in a drain pan.

F

IG. 7

See F

IG. 7 for steps 1-3, except where noted.

1. Place adapter (43) in a vise. Remove four cap-

screws (46). Pull bottom cap (32) off adapter (43). If

needed, replace seals as described on page 10.

2. Loosen both nuts on fluid tube (45). Use a wrench to

rotate tube fittings (1, 60) to the side and then

remove tube (45). Check o-rings (1a, 60a) on fittings

and replace them if they are worn or damaged.

Install plugs in fittings to prevent contamination. See

F

IG. 4 and Reciprocator Parts drawing, page 18.

3. Remove capscrew (3), nuts (36) and lockwashers

(37) on top of reciprocator.

• Clean and inspect all parts for wear or damage.

Replace worn parts as needed. For best

results, always replace all the o-rings and seals

when you disassemble the pump. Repair Kit

247455 is available. Parts included in the kit

are marked with an asterisk, for example (23*),

in the text and drawings. Always replace seals

(23* and 24*) and seals (16* and 44*) together.

• Assembly tool 189305 is required for reassem-

bling the reciprocator.

•Loctite

®

242 thread sealant and Loctite

®

Primer T or Perma-Loc

®

115 thread sealant

and Perma-Bond

®

Surface Conditioner I are

required. Be sure their shelf life is within the

manufacturer’s recommendations.

• Use Loctite

®

609 on yoke (9) and rod (12) on

page 13, step 9 only. Use Loctite

®

242 or

Perma-Loc

®

115 on other threaded surfaces as

required.

3, 39, 2

36, 37

32

43

46

(hidden from view)

ti10602a