7

Combi HP thermostatic mixer shower

Exposed

Note: The outlet of the shower must not be

connected to anything other than the hose and

showerhead supplied.

DO NOT use jointing compounds on any pipe

fittings for the installation.

DO NOT

solder fittings near of the shower unit,

as heat transfer can damage components.

Note: Suitable isolating valves (complying with

Water Regulations) must be fitted on the hot

and cold water supplies to the shower as an

independent means of isolating water supplies

should maintenance or servicing be necessary.

When connecting pipework avoid using tight

90° elbows. Swept or formed bends will give the

best performance.

IMPORTANT:

The water circuit should be

installed such that the flow is not significantly

affected by other taps and appliances being

operated elsewhere on the premises. Water

pressure must not fall below specification of

the shower.

Note: The hot water pipe entry must be on the

left.

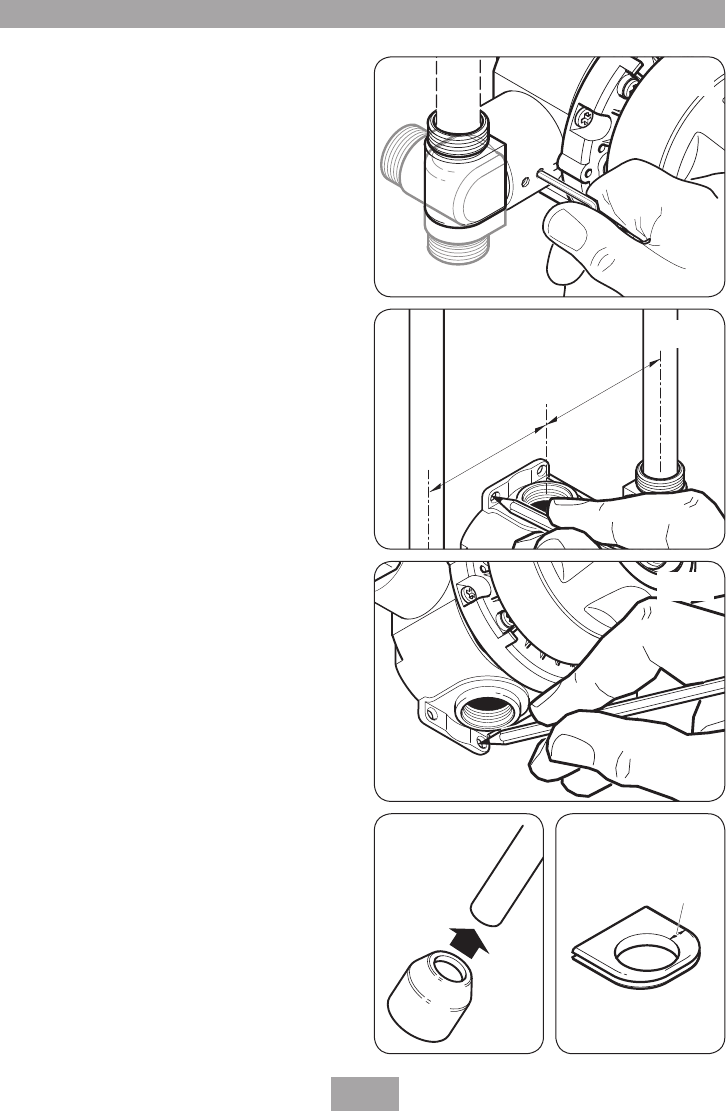

Rising and falling supplies

Having decided on the position of the shower

and direction of pipe entry, complete the

pipework to the shower area.

Note: The final separation between pipe

centres needs to be about 153 mm but absolute

accuracy is not needed as the inlet elbows are

adjustable between 146 mm and 160 mm.

Flush pipework to clear the system of all

debris and check for leaks.

IMPORTANT:

The inlet elbows contain check

valves that may be damaged if debris is not

flushed through prior to fitting.

Where this is not possible refer to the

‘flushing

procedure’ on page 20.

Clip the pipework to the wall surface so that the

pipe centres are 21 mm off the wall.

Offer the valve, together with the inlet elbows,

to the pipework. Make sure the inlet elbow grub

FITTING THE SHOWER TO THE WALL - EXPOSED

FITTING THE SHOWER TO THE WALL

T00227

Fig.8

T00228

=

=

Fig.9

T00229

Fig.10

T00230

T00231

/RQJ

VLGH

Fig.11 Fig.12