10

Combi HP thermostatic mixer shower

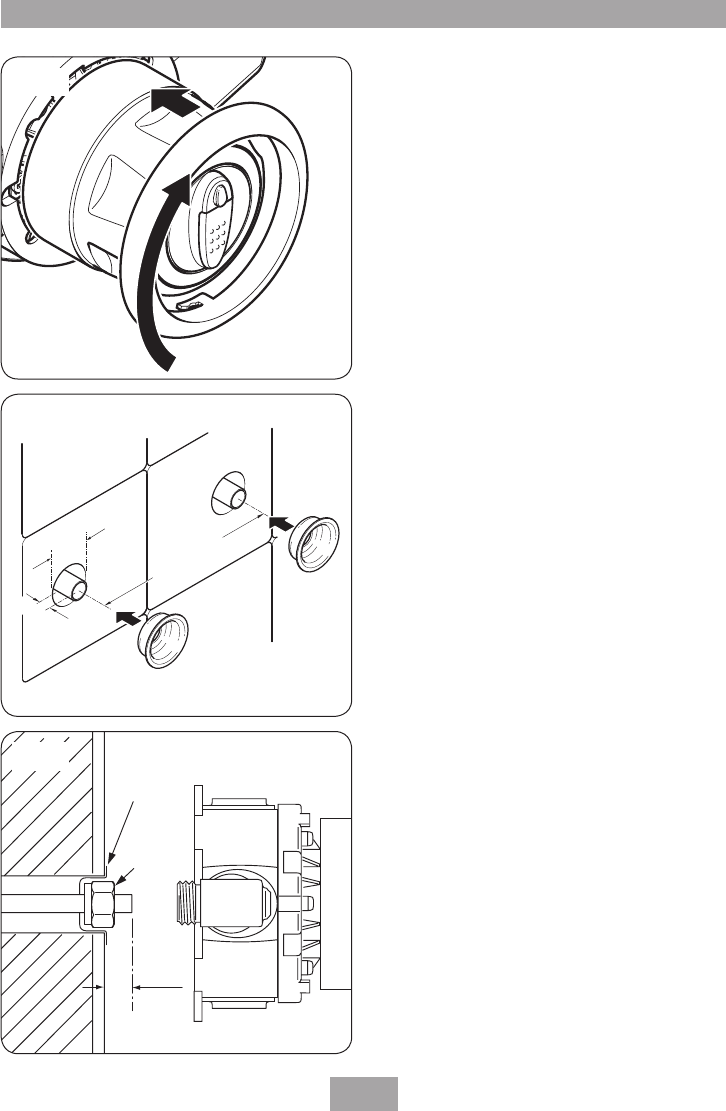

Rear entry supplies

Note: The final separation between pipe

centres needs to be about 153 mm but absolute

accuracy is not essential as the inlet elbows

are adjustable between 146 mm and 160 mm

(fig.23).

Using a spirit level, mark the route of incoming

hot and cold water supply pipes at a distance of

153 mm centres.

Remove the plaster and brickwork to the

required depth to conceal the supply pipework.

Note: It is advisable that pipework installed

in solid walls be provided with enough free

play inside a cavity to allow entry into the inlet

elbows for tightening, before securing the valve

to the finished wall surface.

Install the hot and cold pipework — the hot pipe

must enter from the left. Make sure the finished

pipework projects from the front face of the tiled

surface of the wall by 9.5 mm (fig.24).

Allow for two circular recesses measuring 32 mm

diameter by 14 mm depth, to accept the rear

entry pipe trims (fig.23).

Flush pipework to clear the system of all

debris and check for leaks.

IMPORTANT:

The inlet elbows contain check

valves that may be damaged if debris is not

flushed through prior to fitting.

Where this is not possible refer to the

‘flushing

procedure’ on page 20.

Make good the wall and complete the tiling.

Check that the rear entry pipe trims are sealed in

with either silicon sealant or grout (fig.24).

Note: Failure to fit the rear entry pipe trims

could result in the entry of water into the wall

cavity.

Offer the valve, together with the inlet elbows,

to the pipework making sure the inlet elbow

grub screws are slack allowing the inlet elbows

to be rotated to the correct position and move

freely in and out of the valve housing (fig.8).

Check that the valve is central between the

two pipes, then mark two diagonal fixing holes

(figs.25 and 26).

T00242

T00244

9.5

mm

Pipe

trim

Inlet

nut

T00243

32 m

m

dia

.

9.5 mm

153 m

m approx

Fig.22

Fig.23

Fig.24